PCB design: what is ffc wiring and what is fpc wiring?

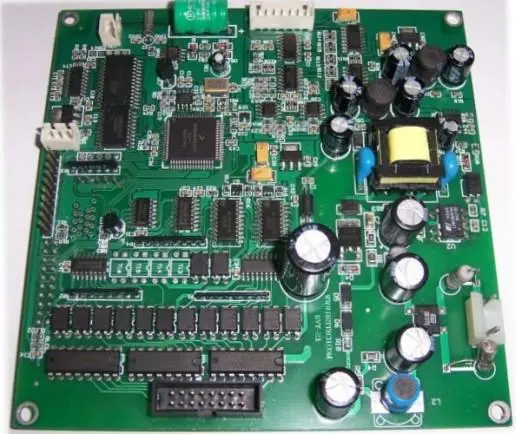

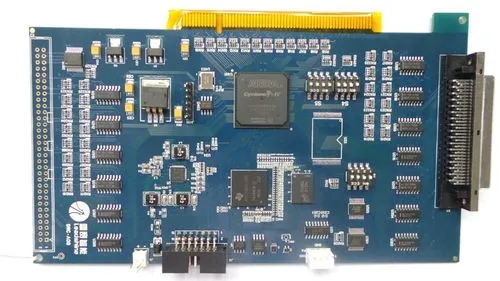

Wiring, also known as flexible circuit board (FPC) It is used for data transmission of active components and areas, such as the hard disk connected to the computer motherboard, the data cable of the optical drive, the data cable of the mobile phone motherboard connected to the display screen, and so on. Devices that are also connected between data lines are collectively referred to as cabling. The cable arrangement mode is mainly divided into round head (R-FFC is directly welded) and flat head (short FFC, socket insertion). It is most suitable for data transmission cables between mobile parts and mainboards, boards and miniaturized electrical equipment. Because the price of FFC flat cable is better than FPC (flexible printed circuit), its application will be more and more extensive. In most places where FPC is used, FFC can basically be used instead.

Wiring characteristics

The wire layout is small and the weight is light. The original designed wiring board is used to replace larger wire harness. Cabling is usually a solution for miniaturization and mobility on the currently cut TING edge assembly board. Wire placement (sometimes referred to as flexible printed circuits) is to etch copper circuits or print polymer thick film circuits on polymer substrates. For thin, light, compact and complex devices, design solutions range from single-sided conductive circuits to complex multi-layer 3D prototype PCB assembly. The total weight and volume of the flat cable is 70% less than that of the traditional round harness. Wire placement can also provide additional mechanical stability by using reinforcing materials to increase strength or lining.

2. The wire can be moved, bent and twisted without damaging the wire, and can adapt to different shapes and special package sizes. The only limitation is volume space. Because it can withstand millions of times of dynamic bending, cabling can be well applied to the continuous or periodic movement of internal systems as part of the final product function. Solder joints on rigid PCB are subject to thermal mechanical stress and fail after hundreds of cycles. Some products with small shape factor/package size benefit from wire placement.

3. The wiring has excellent electrical and dielectric properties, "said the heat-resistant CEO. LT Electronics. "Low dielectric constant allows fast transmission of electrical signals; good thermal performance makes the element easy to cool; higher glass transition temperature or melting point makes the element work well at higher temperatures.

4. Wiring has higher assembly reliability and quality. Wiring reduces the hardware required for internal wiring, such as solder joints, trunk lines, backplane lines and cables commonly used in traditional electronic packaging, so that wiring can provide higher assembly reliability and quality. It is precisely because of the small size of circuit board components that less materials are used. " With the emergence of quality engineering, a thin flexible system is designed to be assembled in only one way, thus eliminating many human errors usually associated with independent cabling engineering.

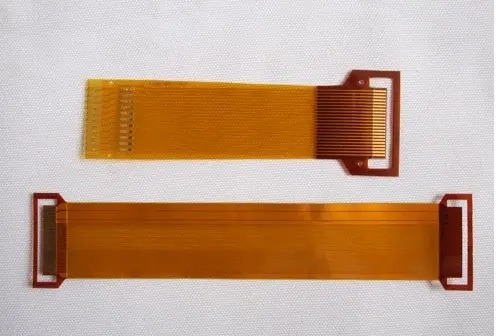

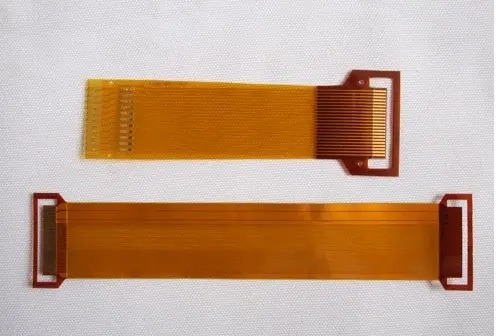

What is FFC wiring

FFC cabling is also known as flexible flat cable. The number and spacing of conductors can be arbitrarily selected to make cabling more convenient, greatly reduce the volume of electronic products, reduce production costs, and improve production efficiency. It is most suitable for moving parts and motherboards. PCB board is used for data transmission cable between PCB board and miniaturized electrical equipment. Common specifications include 0.5mm/0.8mm/1.0mm/1.25mm/1.27mm/1.5mm/2.0mm/2.54mm, etc.

Line arrangement difference between FFC and FPC

FPCs are flexible printed circuits. As far as their manufacturing is concerned, they are formed in different ways:

1. FPC is a flexible circuit board with different single-sided and double-sided, multi-layer pcb structures, which is chemically etched by FCCL (flexible copper foil).

2. FFC is made of flat copper foil and two layers of insulating foil film. The finished product is simple and thick. PCB design and PCB processing manufacturers introduce PCB design: what is ffc wiring and what is fpc wiring?