Once electrostatic discharge occurs in the grounding design, it should be bypassed as soon as possible and should not directly invade the internal circuit. For example, if the internal circuit is shielded by a metal case, the case should be well grounded, and the PCB grounding resistance should be as small as possible, so that the discharge current can be discharged from the outside of the case

Grounding design

Once electrostatic discharge occurs, it should be bypassed as soon as possible, and do not directly invade the internal circuit. For example, if the internal circuit is shielded by a metal case, the case shall be well grounded, and the grounding resistance shall be as small as possible, so that the discharge current can flow into the ground from the outer layer of the case, and the disturbance generated when discharging the surrounding objects can also be introduced into the ground, without affecting the internal circuit. For metal chassis, the circuit inside the chassis is usually grounded through I/O cables, power lines, etc. When electrostatic discharge occurs on the chassis, the potential of the chassis rises, while the potential of the internal PCB circuit is kept near the ground potential due to grounding. At this time, there is a large potential difference between the chassis and the circuit. This will cause a secondary arc between the chassis and the circuit. Damage the circuit. The secondary arc can be avoided by increasing the distance between the circuit and the housing. When the distance between the circuit and the enclosure cannot be increased, a layer of grounded metal baffle can be added between the enclosure and the circuit to block the arc. If the circuit is connected with the chassis, it shall be connected through only one point. Prevent current from flowing through the circuit. The connection point between the circuit board and the chassis shall be at the cable inlet. For plastic chassis, there is no problem of chassis grounding.

Cable design

A properly designed cable protection system may be the key to improve the non susceptibility of system ESD. As the largest "antenna" in most systems, I/O cables are particularly vulnerable to ESD interference to induce large voltage or current. On the other hand, the cable also provides a low impedance channel for ESD interference if the cable shield is connected to the enclosure ground. Through this channel, the ESD interference energy can be released from the system grounding loop, thus indirectly avoiding conductive coupling. In order to reduce ESD interference radiation coupling to the cable, the line length and loop area should be reduced, common mode coupling should be suppressed and metal shielding should be used. Shielded cables, common mode chokes, overvoltage clamping circuits and cable bypass filters can be used for input/output cables. At both ends of the cable, the cable shield must be connected with the shell shield. Installing a common mode choke on the interconnection cable can make the common mode voltage drop caused by electrostatic discharge on the choke rather than on the circuit at the other end. When the two enclosures are connected by shielded cables, the two enclosures are connected together by the shielding layer of the cables, so that the potential difference between the two enclosures can be minimized. Here, the bonding mode between the chassis and the cable shielding layer is very important. It is strongly recommended to overlap 360 ° between the chassis and the cable shield at both ends of the cable.

Keyboard and Panel

The keyboard and control PCB panel must be designed to ensure that the discharge current can flow directly to the ground without passing through the sensitive circuit. For insulated keyboard, a discharge protector (such as metal bracket) shall be installed between the key and the circuit to provide a discharge path for the discharge current. The discharge protector shall be directly connected to the chassis or rack, but not to the circuit ground. Of course, the use of larger buttons (to increase the distance between the operator and the internal line) can directly prevent electrostatic discharge. The keyboard and control panel shall be designed so that the discharge current can directly reach the ground without passing through the sensitive circuit. Insulated shaft and large knob can prevent discharge to control key or potentiometer. Now, more electronic product panels use film buttons and film display windows. Because the film is composed of high-voltage resistant insulating materials, it can effectively prevent ESD from entering the internal circuit through the buttons and display windows to cause interference. In addition, the keys of most keyboards now are lined with high-voltage resistant insulating film, which can effectively prevent ESD interference.

circuit design

The unused input terminals in the equipment are not allowed to be disconnected or suspended, but should be connected to the ground wire or power supply terminal directly or through appropriate resistance. Generally speaking, the interface circuit connected with the external equipment needs to be protected, including the power line, which is often ignored by the hardware design. Taking microcomputer as an example, it should be considered to arrange the links of protection circuit: serial communication interface, parallel communication interface, keyboard interface, display interface, etc.

Filters (shunt capacitors or a series of inductors or a combination of both) must be used in the circuit to prevent EMI coupling to the device. If the input is high impedance, a shunt capacitor filter is most effective, because its low impedance will effectively bypass the high input impedance. The closer the shunt capacitor is to the input, the better. If the input impedance is low, the best filter can be provided by using a series of ferrite, which should also be as close to the input as possible.

Strengthen protective measures on internal circuits. For ports that may suffer from direct conducted electrostatic discharge interference, PCB resistors or parallel diodes can be connected in series at the I/O interface to the positive and negative power supply terminals. The input end of MOS tube is connected with a 100k Ω resistor in series, and the output end is connected with a 1k Ω resistor in series to limit the discharge current. The input end of TTL pipe is connected with a 22~100 Ω resistor in series, and the output end is connected with a 22~47 Ω resistor in series. The input end of the analog tube is connected in series with 100 Ω~100k Ω, and a parallel diode is added to shunt the discharge current to the positive or negative pole of the power supply. The output end of the analog tube is connected in series with a resistance of 100 Ω. Installing a capacitor to the ground on the I/O signal line can shunt the electrostatic discharge current induced on the interface cable to the chassis to avoid flowing to the circuit. But this capacitor will also shunt the current on the housing to the signal line. To avoid this, a ferrite bead can be installed between the bypass capacitor and the circuit board to increase the impedance of the path to the circuit board. It should be noted that the withstand voltage of capacitor must meet the requirements. Electrostatic discharge voltage can be as high as thousands of volts. A transient protective diode can also effectively protect electrostatic discharge, but it should be noted that although the diode limits the voltage of transient interference, the high-frequency interference component has not decreased. Generally, the circuit should have a high-frequency bypass capacitor in parallel with the transient protective diode to suppress high-frequency interference. Gate circuit and gate pulse shall be adopted in circuit design and circuit board wiring. This input mode can only be damaged when electrostatic discharge and gating occur at the same time. However, the pulse edge trigger input mode is very sensitive to the transient caused by electrostatic discharge, and should not be used.

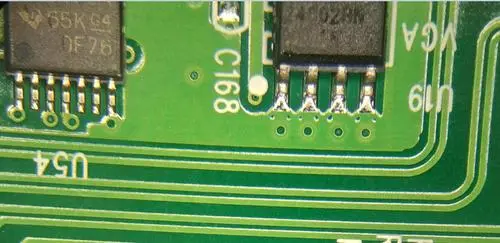

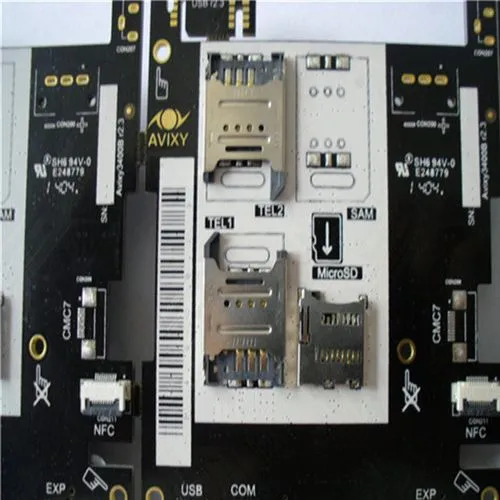

PCB design

Good PCB design can effectively reduce the impact of ESD interference on products, which is also an important part of ESD design in EMC design. You can get detailed guidance from that part of the course. When EMC countermeasures are taken for a finished product, it is difficult to redesign PCB (the cost of improvement is too high), so it will not be introduced here

Software

In addition to the hardware measures, the software suppression scheme is also a powerful method to reduce the system lock and other serious disorders. Software ESD suppression measures are divided into two common categories: refresh, check, and restore. Refreshing involves periodically resetting to the rest state, and refreshing the display and indicator states. You only need to refresh once and assume that the state is correct. You don't need to do anything else. The check/restore process is used to determine whether the program is correctly executed. They are activated at a certain interval to confirm whether the program is completing a function. If these functions are not implemented, a recovery procedure is activated.

General ESD countermeasures:

(1) Add protective diodes in sensitive CMOS and MOS devices;

(2) The sensitive transmission line (including ground wire) is connected with dozens of ohm resistance or ferrite beads;

(3) The electrostatic protection surface coating technology is used to make the ESD hard to discharge, which has been proved to be very effective;

(4) Try to use shielded cables;

(5) Install a filter at the sensitive interface; And isolate the sensitive interfaces that cannot be installed with filters;

(6) Select logic circuit with low pulse frequency;

(7) The shell shield shall be well grounded.