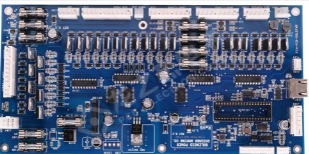

It has been a long time since the development of circuit board production. From the earliest state-owned enterprises, research institutes and other R&D and production, there have also been many people struggling for the development of circuit board industry in this process. Now let's briefly understand the

Circuit board factory

In the 1950s, there were PCB and CCL R&D centers in China, such as 10 institutes, 15 institutes, Shanghai 615 Institute, Nanjing 734 Factory, Jiangnan Computing Technology Institute, etc. A large number of old experts, represented by Yu Tiezhong, Yao Shouren, Li Shihao, Gu Changyin, Lin Jindu, Gu Xinshi, Guo Guiting, etc., have appeared. They have contributed their youth to the development of China's electronic circuits together with the majority of employees for half a century. Today, I want to introduce the substrate for printed boards of the circuit board factory.

Introduction of Substrates for Printed Boards in Circuit Board Factory

(1) Epoxy glass cloth copper clad plate is made of electronic grade glass fiber cloth as reinforcement and epoxy resin as adhesive. The epoxy glass cloth CCL has good electrical performance, high mechanical strength, and little change due to environmental impact. Its performance is better than that of phenolic paper based CCL, but its cost is correspondingly higher for circuit board manufacturers. Most of the epoxy glass cloth copper clad plates are used to make double-sided printed boards and multilayer printed boards. They are used in durable electronic equipment such as computers, communication equipment, commercial machines and industrial instruments. With epoxy resin modified, the electrical performance and heat resistance are better. High performance epoxy glass cloth copper clad plates are used in digital high-frequency high-speed equipment.

(2) Composite copper clad laminate is made of epoxy resin as adhesive, glass fiber felt core or paper fiber core and glass cloth surface pasted on both sides as reinforcement. The performance and price of composite copper clad laminate are between paper based copper clad laminate and glass cloth copper clad laminate, which can be processed by punching. It is applicable to many circuit board factories in civil consumer equipment that require high mechanical strength and good electrical performance.

(3) Copper clad laminate with special performance requirements. There are many different resin components of copper clad laminate to meet the special performance requirements of printed PCB. Such as modified epoxy resin, polyimide resin (PI: Polyimide), bismaleimide triazine resin (BT), polytetrafluoroethylene (PTFE), cyanate ester resin, polyphenylene ether (PPE), etc., to improve the heat resistance, dielectric constant and dimensional stability of copper clad laminate. In addition, there is a metal base copper clad plate composed of a metal plate, an insulating dielectric layer and a copper foil, including a metal substrate exposed on one side and a coated metal core plate. Gold coated plates include molybdenum plates, copper plates or copper plates. These metal based copper clad plates have high mechanical strength, excellent heat dissipation, dimensional stability, electromagnetic shielding and other advantages. These special copper clad laminates have high relative cost and special processability, and are used in equipment with special requirements.

(4) Flexible copper clad laminate is composed of flexible insulating layer and copper foil. The commonly used insulating layer is polyimide (PI) film or poly (ethylene terephthalate) film with film thickness of 25 jLm, 50 | xm, 75 | jLm, etc.

Polyimide flexible copper clad laminate has good electrical performance, high heat resistance and high cost, and is commonly used in durable electronic equipment, such as computers and mobile phones. Polyester sintered copper clad laminate has good dielectric properties, low cost, but poor heat resistance, and is commonly used in PCB equipment with low requirements. The flame retardant used in the base material is a halogen compound containing bromine, which is harmful to human health and will be prohibited from use. Environmental friendly copper clad laminate with halogen-free flame retardant is now advocated.

Distinguished according to the special performance of copper clad laminate:

① According to the fire resistance of CCL, there are fire retardant and non fire retardant boards. According to UL standard, non flame retardant board is HB grade; Flame retardant board has V0 grade. FR: flame retardant refers to that the base material of CCL has the characteristics of preventing or retarding the spread of flame, and those with "FR" in the specification code of CCL are flame Retardant.

② High Tg copper clad laminate. Tg is the glass transition temperature of the material. Tg high copper clad laminate has good heat resistance and dimensional stability. High Tg copper clad laminate means that its Tg is above 170t.

③ Low dielectric constant copper clad plate refers to the substrate whose dielectric constant is stable at about 3 at 1GHz and dielectric loss is not greater than 0.001. This kind of substrate is suitable for high frequency circuit, also called high frequency substrate.

④ High CTI copper clad plate 〇 CTI refers to the tracking index of comparative leakage, which refers to the combined action of electric field and electrolyte on the surface of insulating layer

The phenomenon of conducting electricity due to the gradual formation of carbonization reflects the electrical safety of the substrate.

⑤ Low CTE copper clad plate. CTE is the coefficient of thermal expansion, and the coefficient of thermal expansion of low CTE substrate in X and Y directions should generally be 21.