Building 6, Zone 3, Yuekang Road,Bao'an District, Shenzhen, China

+86-13410863085Mon.-Sat.08:00-20:00

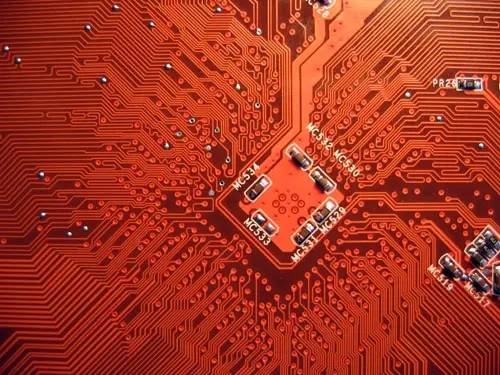

Marking of SMD resistance and function of SMD adhesive

Marking method on SMT chip resistor

As an important part of SMT chip processing, chip resistors are usually small in size, so they are usually printed with numbers and letters instead of words. What do these characters mean? Next, let me show you how to quickly identify these resistors.

1. Nominal method of digital cable location

J-means the accuracy is 5%, F-means the accuracy is 1%.

(1) The 5% precision resistance value indicates: the first two digits indicate the effective real number, the third digit indicates the number of zeros, and the basic organization is Î), for example: 302=3000=3K Î), and the third digit "2" indicates two zeros. Mainly used for E24 series.

(2) The 1% precision resistance value indicates that the first three bits are effective real numbers, the fourth bit indicates how many zeros there are, and the basic organization is Î, for example: 3002=30000 Î), and the fourth bit "2" indicates two zeros. Mainly used for E24 and E29 series.

(3) If it is a decimal point, use R to represent the decimal point, for example: 3R5 represents 3.5 Î ©, R35 represents 0.35 Î ©

2. Color circle naming method

SMD resistors are the same as ordinary resistors. Most of them use four rings (sometimes three) to express their resistance. The first ring and the second ring are significant figures, and the third ring is the magnification. For example, "brown green black" means 15 ° C); "Blue Grey Liuding Silver" means "68k Î ©” The error is ± 10%.

You need to look up the code table for the E96 series. There is a special table, such as 39X, where 39 represents 249, and X represents a power from 10 to - 1, i.e. 24.9 Î).

Different SMT manufacturers have different printing rules for chip resistors, but in general, most of the rules follow sub rules

Function of patch adhesive

SMT adhesive or SMT patch adhesive plays a special role in SMT patch processing. The heat hardening process of SMT patch adhesive is irreversible. Glue has this feature, and it is usually produced together with parts to complete the processing of circuit boards.

Function of patch adhesive

1. During SMT wave soldering, components can be fixed on the circuit board to prevent components from falling when the circuit board passes through the solder slot.

2. In the process of double-sided reflow welding, the use of patch adhesive can prevent large parts on the welded side from falling due to the heating and melting of solder.

3. During reflow welding and precoating, it can prevent displacement and stand upright during installation.

4. When replacing circuit boards and components in batches, the patch adhesive can be used for marking.

5. Easy to replace parts

6. Stable dosage

7. Fast curing epoxy adhesive, thixotropic effect and airless state. It is very suitable for dispensing of high-speed mounters and has good shape control of dispensing points.

Patch adhesive is widely used for patch processing For double-sided circuit boards, SMT patch red glue is usually used to prevent some components from falling Because the application effect of the patch adhesive will be affected by the thermal curing conditions, the objects to be connected, the equipment to be used, the operating environment, and the selection of the patch adhesive should be determined according to the production process

Marking method on SMT chip resistor

As an important part of SMT chip processing, chip resistors are usually small in size, so they are usually printed with numbers and letters instead of words. What do these characters mean? Next, let me show you how to quickly identify these resistors.

1. Nominal method of digital cable location

J-means the accuracy is 5%, F-means the accuracy is 1%.

(1) The 5% precision resistance value indicates: the first two digits indicate the effective real number, the third digit indicates the number of zeros, and the basic organization is Î), for example: 302=3000=3K Î), and the third digit "2" indicates two zeros. Mainly used for E24 series.

(2) The 1% precision resistance value indicates that the first three bits are effective real numbers, the fourth bit indicates how many zeros there are, and the basic organization is Î, for example: 3002=30000 Î), and the fourth bit "2" indicates two zeros. Mainly used for E24 and E29 series.

(3) If it is a decimal point, use R to represent the decimal point, for example: 3R5 represents 3.5 Î ©, R35 represents 0.35 Î ©

2. Color circle naming method

SMD resistors are the same as ordinary resistors. Most of them use four rings (sometimes three) to express their resistance. The first ring and the second ring are significant figures, and the third ring is the magnification. For example, "brown green black" means 15 ° C); "Blue Grey Liuding Silver" means "68k Î ©” The error is ± 10%.

You need to look up the code table for the E96 series. There is a special table, such as 39X, where 39 represents 249, and X represents a power from 10 to - 1, i.e. 24.9 Î).

Different SMT manufacturers have different printing rules for chip resistors, but in general, most of the rules follow sub rules

Function of patch adhesive

SMT adhesive or SMT patch adhesive plays a special role in SMT patch processing. The heat hardening process of SMT patch adhesive is irreversible. Glue has this feature, and it is usually produced together with parts to complete the processing of circuit boards.

Function of patch adhesive

1. During SMT wave soldering, components can be fixed on the circuit board to prevent components from falling when the circuit board passes through the solder slot.

2. In the process of double-sided reflow welding, the use of patch adhesive can prevent large parts on the welded side from falling due to the heating and melting of solder.

3. During reflow welding and precoating, it can prevent displacement and stand upright during installation.

4. When replacing circuit boards and components in batches, the patch adhesive can be used for marking.

5. Easy to replace parts

6. Stable dosage

7. Fast curing epoxy adhesive, thixotropic effect and airless state. It is very suitable for dispensing of high-speed mounters and has good shape control of dispensing points.

Patch adhesive is widely used for patch processing For double-sided circuit boards, SMT patch red glue is usually used to prevent some components from falling Because the application effect of the patch adhesive will be affected by the thermal curing conditions, the objects to be connected, the equipment to be used, the operating environment, and the selection of the patch adhesive should be determined according to the production process

Just upload Gerber files, BOM files and design files, and the KINGFORD team will provide a complete quotation within 24h.