PCBA test in MSL electronics and PCBA processing

In many aspects of PCBA processing, EMS electronic manufacturers often encounter humidity sensitive electronic components. It must be noted that Due to improper management of humidity sensitive components, this will directly lead to poor welding, resulting in defects such as wrong welding, continuous tin, and low tin The management of humidity sensor mainly includes two aspects: storage and feeding

Each humidity sensor has its MSL (humidity sensitivity level), which clearly defines the maximum exposure time and feed interval allowed by the humidity sensor. Once the agreement is exceeded, it must be baked strictly before going online. Humidity sensitive parts are usually stored in moisture resistant cabinets with specific functions. It is recommended to install a specific temperature and humidity alarm on the moisture-proof cabinet to remind the warehouse staff that once the humidity exceeds the standard, the alarm and manual intervention will be carried out. When taking out, check the condition of the humidity label card, and record the time of taking out and returning the remaining data to the box.

There are 8 levels of MSL classification

Level 1 - less than or equal to 30 ° C/85% RH, unlimited floor life

Level 2 - less than or equal to 30 ° C/60% RH one year floor life

Class 2a is less than or equal to 30 ° C/60% relative humidity and the service life of surrounding floors

Level 3 - less than or equal to 30 ° C/60% RH 168 hour floor life

Level 4 - less than or equal to 30 ° C/60% RH 72 hours floor life

Level 5 - less than or equal to 30 ° C/60% RH 48 hour floor life

Class 5a is less than or equal to 30 ° C/60% relative humidity 24 hours of floor life

Grade 6 - less than or equal to 30 ° C/60% RH for a 12 hour working life (for Grade 6, the components must be baked before use and must be refluxed within the time limit specified on the humidity sensitive caution label)

The MSL determination process is:

(1) A good IC performs SAT to confirm that there is no delamination.

(2) Bake the IC to completely remove moisture.

(3) Humidify according to MSL level.

(4) Reflow through infrared for 3 times (analogy IC upload, repair and disassembly, repair and upload).

(5) SAT test whether there is layering phenomenon and IC test function.

If the above tests can be passed, it indicates that the IC package meets the MSL standard.

Generally speaking, the factory will formulate strict forms and require operators to strictly register before each picking, inspection and feeding to ensure the validity of the data. The management of humidity sensor is an extremely critical operation requirement in the whole PCBA processing process, which must be strictly managed.

What is the difference between ICT and FCT in PCBA test?

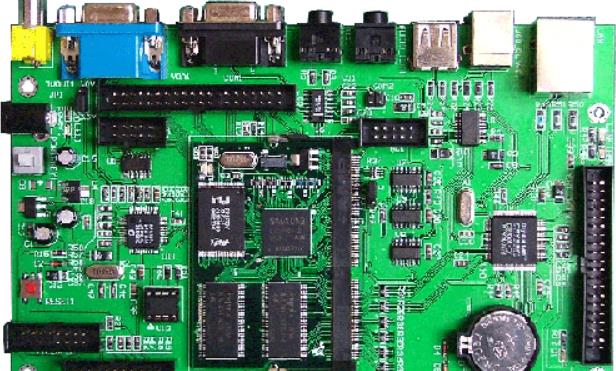

PCBA test is a key step to ensure the delivery quality Generally, the customer needs to provide a test plan, including test points, programs, and test steps PCBA electronic manufacturers shall perform corresponding ICT and FCT tests according to the design archives ICT (In circuit Test, circuit test) is mainly for the component level. By contacting the pin of each component on the PCBA board and measuring whether its value is consistent with the nominal value, it is used to detect resistance and capacitance The value and polarity of inductors and other components are very important means

FCT test

With the rapid development of process capabilities in the electronics industry, ICT testing is becoming less and less, because the quality of many components can reach below 50PPM, fully meeting the processing yield of electronic products At this time, FCT (Function Test) is a particular important The PCBA manufacturer will release the FCT test rack compliance design file, place the PCBA board on the test rack, capture the test points on the PCBA board, write programs through the burner, and then simulate the input and output actions of the product to achieve the test purpose In some cases, PC software is required FCT test is a kind of functional test close to the product level, which can effectively cover the performance range of the product and is a very effective method

The above is the explanation given by the editor of pcb circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High frequency circuit board and SMT chip are waiting for your presence again.