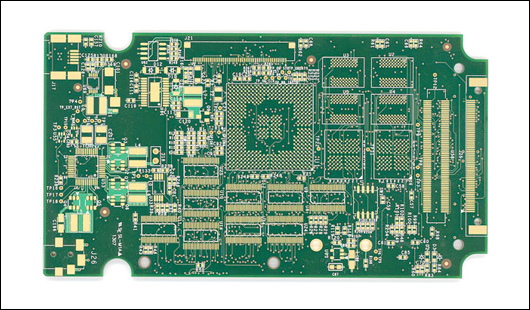

Definition of high TG PCB

A high TG PCB is a board with a high glass transition temperature. "TG" is the temperature point at which the material begins to change from solid state to rubber state. Changes in physical shape will certainly have adverse effects on their functions and performance. If your PCB works under high temperature for a long time, you'd better choose high TG materials.

High TG PCBs indicate that their TG values are generally higher than 170 ° C. Standard PCBs are usually made of materials with a TG value of 140 ° C and can withstand an operating temperature of 110 ° C. However, standard PCBs may not be suitable for extreme temperature environments common in industrial, automotive, and other high temperature electronic applications. When it comes to these situations, FR4 materials will be the best solution.

The thermal resistance of FR4 material is much higher than that of standard polychlorinated biphenyls When selecting a PCB, the TG value should be at least 20-25 ° C higher than the expected operating temperature of the PCB. For example, if the TG value of PCB is 170 ℃, the operating temperature of the device should be lower than 150 ℃.

Importance of High TG PCB

High TG PCB has better performance and stability at high temperature, making it a reasonable solution for high power density design. The higher the TG of the circuit board, the higher the heat resistance, chemical resistance and mechanical stability of the electronic devices.

High TG PCB to multilayer PCB and high-density circuit board These pcbs generate more heat because the components in multilayer PCBs and HDI PCBs are more compact and circuits are very dense. High TG PCBs have good thermal control capability, which helps to ensure the reliability of products during operation.

As we all know, if electronic products often work for a long time, the heat generated in the working process will be transferred to other parts, which will ultimately affect the durability and performance of the products. For some electronic products with multi-function but limited by size and weight, high heat price PCB will be an economical and effective method to improve the efficiency of heat management.