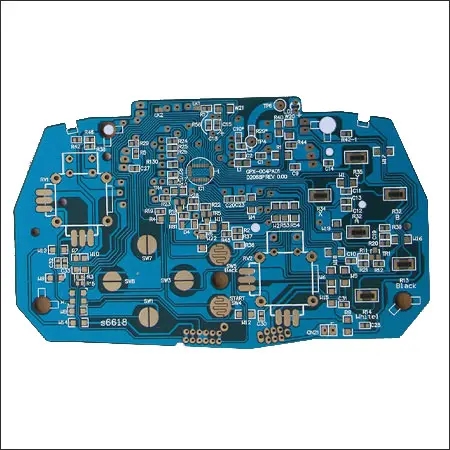

Some defects of SMT chip and some common components processed

Minimization of all weld joint defects should be the goal of any SMT manufacturer. By understanding defects, root causes, and how to prevent SMT chip defects, you can greatly improve the quality of all components you manufacture. According to industry statistics, the top three PCBA assembly defects account for 74% of all manufacturing defects, including short circuit, faulty soldering and component displacement.

Poor soldering 44%

When there is no connection between the lead wire and the pad or other connection points on the PCB cause an open connection, a welded joint occurs. This also happens when the solder only appears on the PCB pad and there is no solder on the component lead.

bridging

Welding bridge (short circuit) 15%

When solder is incorrectly crossed and one lead is connected to another, a short circuit occurs, sometimes referred to as weld bridging. This short dimension can be microscopic and very difficult to detect. If no short circuit is detected, it may cause serious damage to circuit components, such as burning or bursting of components and/or burning of PCB wiring.

Components offset by 15%

Component offset can be described as misalignment between an item and its target. Since the element can float on the molten solder, element displacement may occur during reflow. Parts with many pads (such as BGA parts) may be rearranged due to the surface tension of molten solder, but most of the time the parts will remain where they are placed, which is a sufficient reason to ensure that the parts are accurately placed in their assumed positions in the middle of the mat or land area.

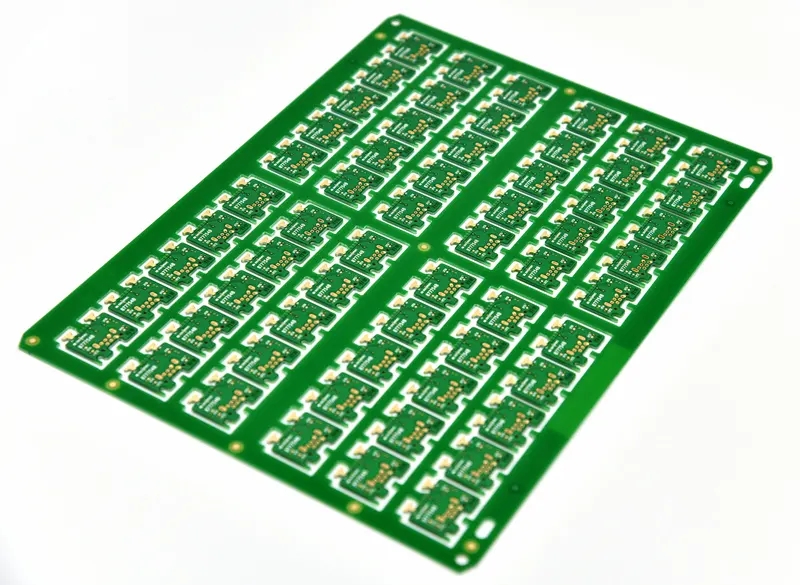

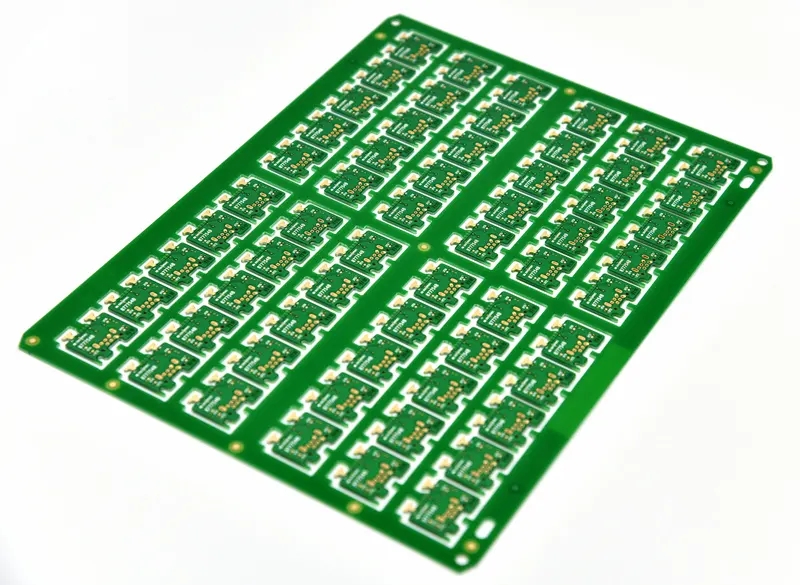

Some common components for SMT chip processing

SMT chip processing customers are very concerned about processing quality, and the quality of chip processing is the top priority. However, for SMT OEM, the selection of electronic components is also one of the key factors affecting product quality. Electronic processing is inseparable from electronic components, and the selection of components is also one of the core issues. It is necessary to ensure the quality of products, but also to control the cost within the budget, so as to achieve the balance between quality and cost. The following professional SMT processing factory will briefly introduce some commonly used components for SMT chip processing.

Common materials for SMT chip processing

1. Chip resistance

Resistance is an electronic component with resistance characteristics, which is widely used in SMT chip processing. Resistors are divided into fixed resistors and variable resistors (potentiometers), which play the role of voltage sharing, shunt and current limiting in the circuit.

2. Chip capacitor

Capacitance is also one of the basic components of SMT processing. It is the storage part of electric energy. It plays the role of coupling, filtering, DC and tuning in electronic circuits.

3. Induction coil

It is also called inductance, which can store magnetic energy. Inductive coil in SMT chip processing is usually composed of frame, winding, shielding cover, iron core, etc. The resistance of the potentiometer can be changed. During SMT processing, the resistance needs to be continuously adjusted within the specified range, which is called potentiometer. The potentiometer is composed of a housing, a sliding end, a rotating shaft, a ring resistor body and three lead ends.

4. Transformer

The transformer is generally composed of iron core and coil. The coil has two or more windings. The winding connected to the power supply is called the primary coil, and the rest is called the secondary coil. When there is AC current in the primary coil, AC magnetic flux will be generated in the magnetic core to induce the voltage in the secondary coil. The transformer is mainly used for AC voltage transformation, current transformation, power transformation, impedance transformation and buffer isolation.

5. Crystal diode

The crystal diode is composed of PN junction, electrode lead and additional sealed housing, and has single conductivity.

6. Field effect transistor

This diode is also a PN junction semiconductor device. Unlike transistors, SMT chips do not use the conductivity of the PN junction, but use its insulation characteristics.

PCB manufacturers, PCB designers and PCBA manufacturers will explain some defects of SMT chips and some common components processed.