Common scraper types and common patch adhesives in SMT processing

Squeegee Type

The most common scraper types in SMT processing are diamond and drag skirt.

1、 Rhombus

The diamond is not very common now. It is composed of a square with a section of about 10 mm x 10 mm. It is clamped by a splint to form a 45 ° angle on both sides. It can work on both sides and only needs a scraper, because it skips the solder paste bar at the end of each stroke. However, one inconvenience is that the solder paste will run upward, and its flexibility is not strong, so it cannot fit PCB very well, which will cause missed printing and easy to get dirty. As shown below:;

diamond

2、 Drag skirt

The drag skirt is very common, which is composed of polyethylene with rectangular section, supported by plywood and requires two scrapers, one in the direction of silk screen travel and one in the direction of silk screen travel. There is no need to skip the solder paste bar, because the solder paste is between two scrapers, and the angle of each stroke can be determined separately. About 40mm scraper is exposed, while solder paste only moves upward for 15-20mm, so this form is cleaner. Before use, the scraper must be adjusted so that its guide edges are straight and parallel. First check whether its edges are straight. If not, adjust the fixing screws of the clamping plate.

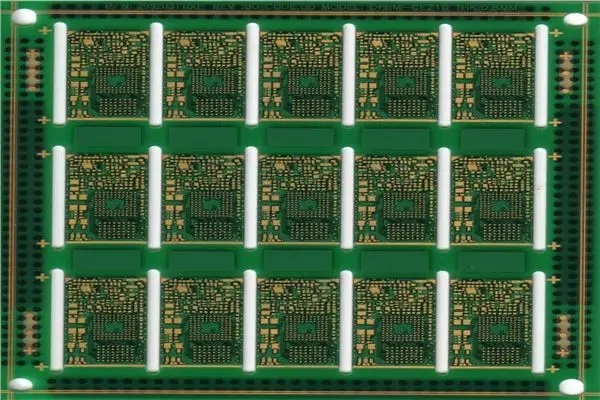

Common SMT pasters and their components

Patch adhesive is also called red adhesive. SMD is mainly used for chip resistor and chip mounting process. It is a necessary bonding material for wave soldering process of surface mount components. Before wave soldering, it is necessary to fix the mounted components on the corresponding positions of PCB with patch adhesive to prevent the components from falling into the tin pot during wave soldering. The quality of chip adhesive directly affects the quality of wave soldering process for chip components. Patch adhesive is mainly composed of bonding material, curing agent, filler and other additives. The commonly used patch adhesives in SMT processing mainly include epoxy resin patch adhesives and acrylic acid patch adhesives.

1、 Epoxy resin patch adhesive

Epoxy resin patch adhesive is the most commonly used patch adhesive in SMT processing. Its components mainly include epoxy resin, curing agent, filler and other additives. The curing mode of epoxy resin patch adhesive is mainly thermal curing. Epoxy resin belongs to thermosetting type. High viscosity adhesive thermosetting adhesive can be divided into single component and two components. However, the two-component adhesive has unstable performance and is rarely used at present.

2、 Acrylic patch adhesive

Acrylic patch adhesive is mainly composed of acrylic resin, light curing agent and filler. It belongs to light curing patch adhesive and uses a single component system. Acrylic patch adhesive is characterized by stable performance, short curing time and sufficient curing, easy control of process conditions, and storage conditions at room temperature and away from light for up to one year, but its bonding strength and electrical performance are not as high as those of epoxy type.