15 points of SMT SMT equipment GKG solder paste printing machine you must know

In SMT processing equipment, many different types of equipment with different functions will be used. There are printing presses, mounters, reflow soldering, dispensing machines, AOI, X-RAY and BGA repair stations. The printing press generally has different brands in China, such as GKG, Desen and Nisson. This article takes GKG solder paste printing machine as an example to lead you to understand the 15 points we must know about the printing machine.

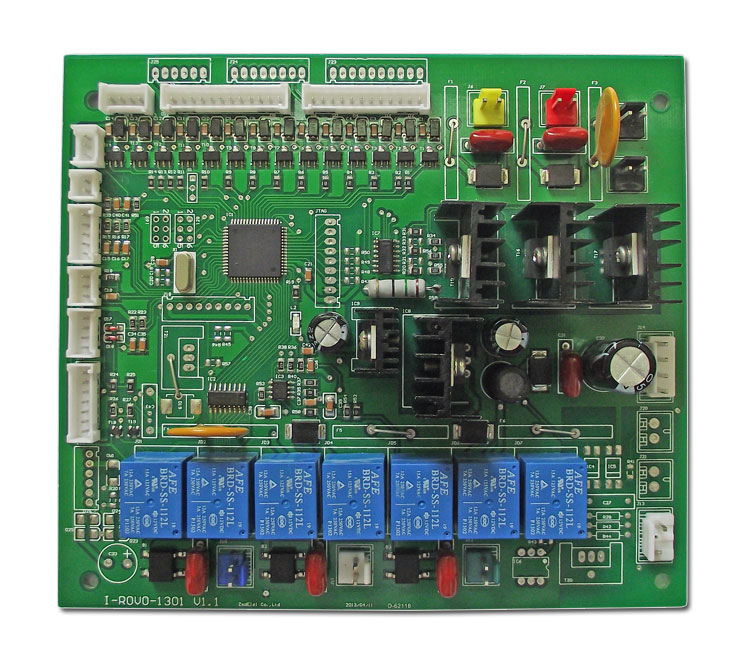

Product introduction:

1) Special manual adjustment platform for GKG full-automatic solder paste printing machine

2) PCB Positioning System of GKG Automatic Solder Paste Printer

3) The CCD part of the automatic solder paste printer is separated from the cleaning part

4) 2D Solder Paste Detection System of Full Automatic Solder Paste Printer

Functions and Features of GKG-K3 Series

1. Precision

GKG patented mathematical operation model ensures that the machine can achieve high-precision alignment and easily realize the printing of 01005.

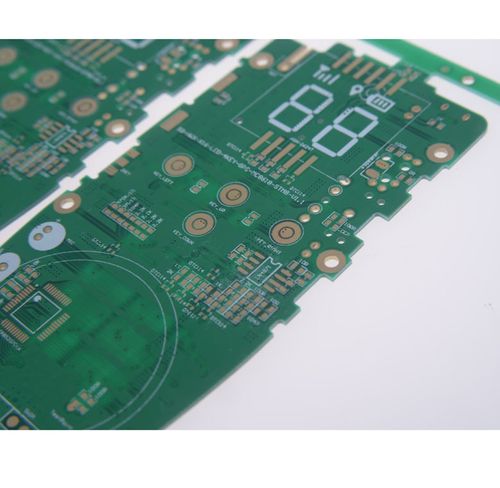

Print size of PCB

Meet the printing of large PCB, and the printing size of large PCB can reach 650X610mm

2. GKG dedicated full-automatic computer controlled PCB thickness adjustment jack platform

Compact and reliable structure, stable lifting, PIN pin height is automatically adjusted by software, which can accurately adjust the position and height of PCB boards with different thicknesses.

3. Image and optical system

The new optical path system - uniform annular light and high brightness coaxial light, together with the brightness function that can be infinitely adjusted, enables all types of Mark points to be well identified (including uneven Mark points), and is suitable for various types of PCB with different colors such as tin plating, copper plating, gold plating, tin spraying, FPC, etc.

Four channels of light source can be adjusted to illuminate the steel mesh and PCB board at the same time.

The large area array digital camera (1.3 million pixels) that simultaneously takes images up and down improves the imaging resolution and image accuracy, ensuring the printing with higher accuracy requirements.

4. Programmable floating self-adjusting stepping motor drives the print head

It is designed according to the different pressure requirements of the front and rear scrapers and the stability of the lifting, to prevent the solder paste from leaking and the flexible clamping design of the blade. The pressure, lifting speed, printing speed and printing range of the scraper can be adjusted by software. It also provides customers with a variety of demoulding methods to adapt to PCB boards with different tin requirements, providing customers with a good printing control platform.

5. Scraper system

The sliding rail scraper system can improve the operation stability and prolong the service life.

A new scraper system with scraper contact induction (the induction device is on the scraper).

Scraper system with pressure closed loop (optional).

6. PCB positioning system of GKG printing machine

Unique belt conveying guide rail, magnetic thimble, vacuum nozzle, original pressing device and flexible side pressing device.

7. Transportation system

Stepping motor and unique belt transmission.

8. Cleaning system

The system provides three cleaning methods: dry cleaning, wet cleaning and vacuum cleaning. These three methods can be used in any combination. When the customer does not need automatic cleaning, manual cleaning can be realized under the production interface, thus reducing the cleaning time and improving the production efficiency.

The new wiping adhesive strip ensures full contact with the steel mesh, and the large vacuum suction ensures that the residual solder paste in the mesh can be eliminated vigorously, so as to truly realize the effective automatic cleaning function.

The CCD part is separated from the cleaning part. When the CCD works, the CCD part moves independently, reducing the load of the servo motor, and improving the speed and accuracy of the machine.

X/Y bidirectional cleaning system

Closer to manual action, perfect cleaning effect, and economical use cost of cleaning solution recovery device.

9. Control system

The American PMAC series motion control card is used as the system control, which can realize the modification of parameters during the movement of the machine, and truly realize the pause function.

10. High adaptability steel mesh frame clamping system

The printing of screen frames of various sizes can be realized, and the machine type can be quickly changed in the production process.

Automatic positioning in Y direction.

11. Simple and user-friendly Chinese/English operation interface

Windows XP operation interface is adopted, which has good man-machine conversation function: especially for the navigation effect of program files, which is convenient for all operators to quickly get familiar with the operation; Menu type Chinese/English switch, operation log, fault record/fault self diagnosis/fault analysis prompt/optical alarm and other functions make the operation simple and convenient.

12. Calibration system (optional)

Through the system, the machine can always maintain the precision state of pcb factory, and ensure the long-term use of the machine.

13. Temperature and humidity control system (optional)

The temperature control system is responsible for monitoring, maintaining and controlling the solder paste temperature in the printing machine to ensure consistent and repeatable printing effect. The temperature is maintained within ± 4 ° C of the temperature difference. The equipment is also responsible for measuring and recording humidity in the printing workshop. Online SPC warns the operator of temperature and humidity fluctuations.

14.2D Solder Paste Printing Quality Inspection and Analysis

It can quickly detect the printing defects such as offset, less tin, missing printing, and even tin to ensure the printing quality.

15. Platform system

The direct connected motor drive is adopted to realize the ultra-fine transmission under the micro adjustment, so that the machine can meet the printing requirements of higher accuracy.