How to check the quality of PCBA coating

The manufacturer of the line bar explained how to check the quality of PCBA coating

There is no adhesion loss, no cavity or bubble, no semi wetting, no crack, no wavy pattern, no fish eye or orange peel peeling at the jumper of adjacent pads or conductor surfaces on PCB; Foreign objects do not affect the minimum electrical clearance between components, pads or conductor surfaces.

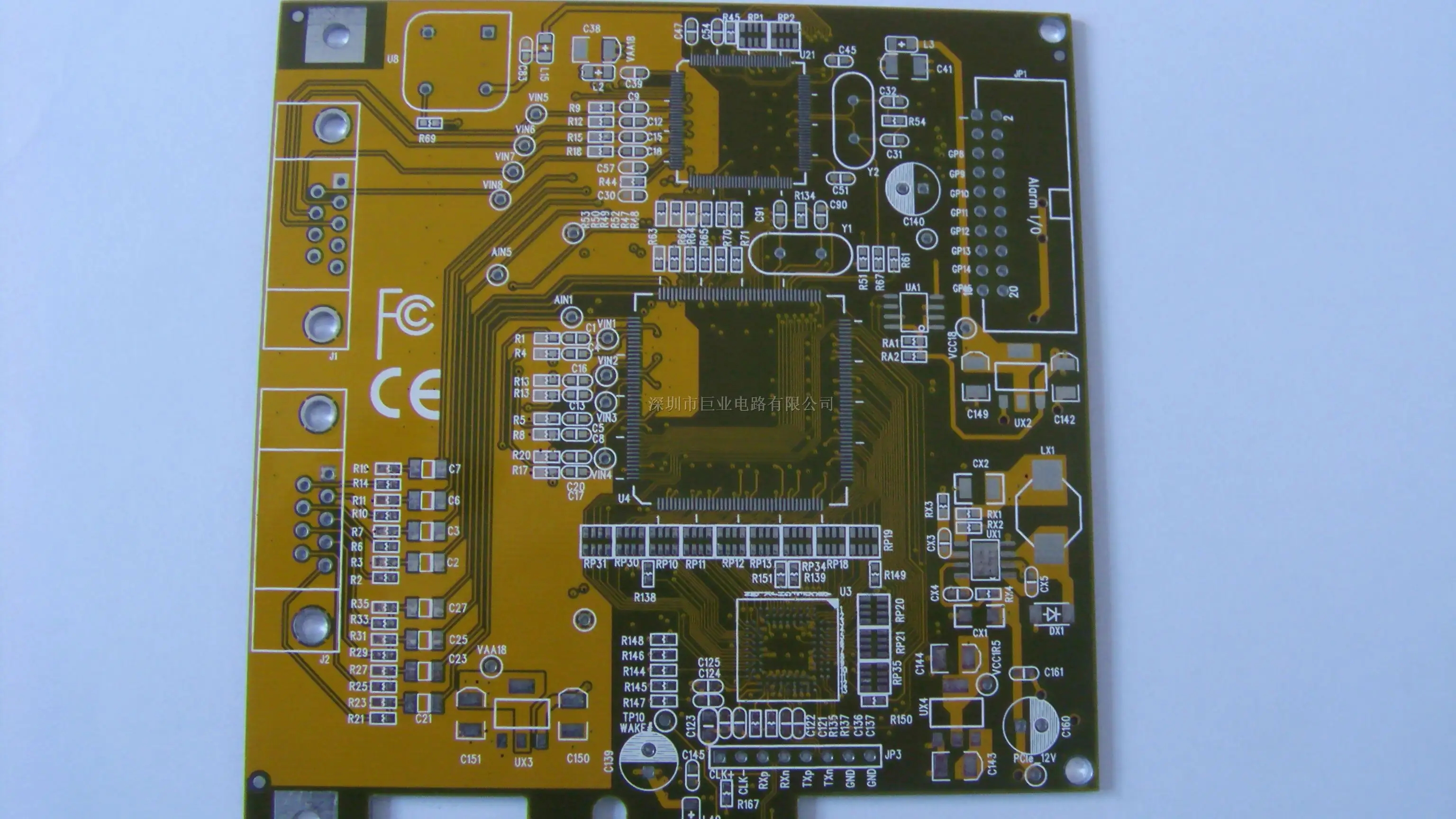

1、 Conformal coating

The coating layer of PCBA shall be transparent and uniformly cover the printed board and components. Whether the coating layer is uniform depends on the coating method to a certain extent, which will affect the appearance of the printed circuit board and the coating condition of the corners. Components coated by dipping during SMT chip processing will have a "deposition line" of paint accumulation, or there will be a small amount of bubbles at the edge of the plate, which will not affect the function and reliability of the coating layer.

How to check the quality of PCBA coating

2、 Coating layer

The coating layer on PCB can be inspected by naked eyes. The coating with fluorescent material can be inspected under dim light, and white light can be used as an auxiliary means for coating layer inspection.

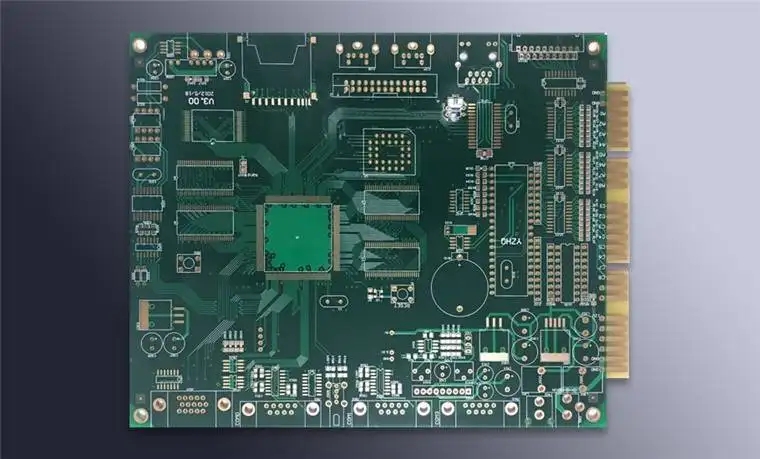

(1) Objectives

● Good adhesion on PCBA components; No bubbles or bubbles.

● There is no semi wetting, powder, peeling, wrinkle (non attachment area) cracking, ripple, fish eye or orange peel peeling through PCBA detection.

● No foreign impurities; No discoloration or transparency reduction; The coating shall be completely cured and uniform.

(2) Acceptable

● The coating is completely cured, uniform and consistent; The area to be coated is covered by the coating; No adhesion to solder mask.

● There is no adhesion loss, no cavity or bubble, no semi wetting, no crack, no wavy pattern, no fish eye or orange peel peeling at the jumper of adjacent pads or conductor surfaces on the PCB; Foreign objects do not affect the minimum electrical clearance between components, pads or conductor surfaces.

● The coating is thin, but it can still cover the edge of components.

(3) Defects

● The coating is not cured (showing viscosity)

● The area to be coated is not coated.

● Missing coating in areas requiring coating.

● Due to obvious loss of adhesion (powder particle), cavity or bubble, semi wetting, crack, ripple, fish eye or orange peel peeling at the jumper of adjacent conductor or PCB pad, the pad or adjacent conductor surface is bridged, exposing the minimum electric gap between the circuit or affected component pad or conductor surface. Discoloration or loss of transparency.

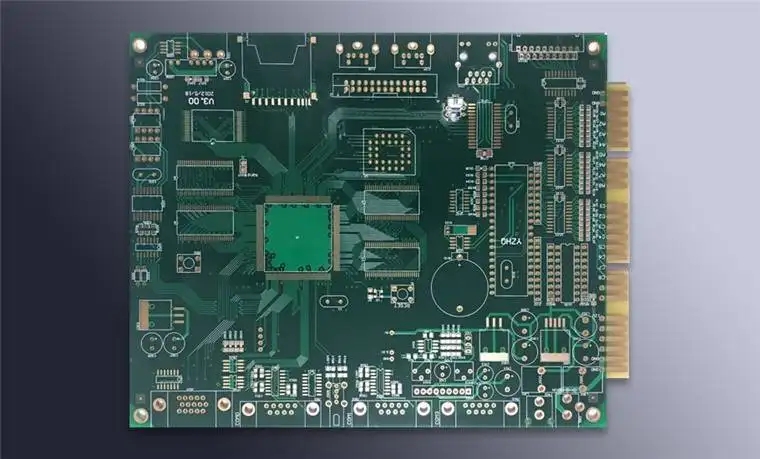

3、 Thickness of conformal coating

The specimen can be the same material as PCBA printed board or other non loose materials, such as metal or glass. Wet film thickness measurement is also a method of coating thickness measurement. It is based on the known dry/wet film thickness conversion relationship to obtain the final coating thickness.