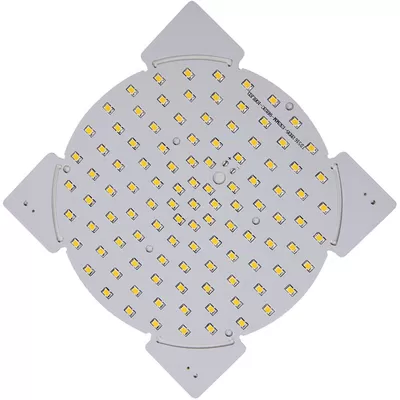

PCB Assembly 10W 56mm Aluminum Plate

Name: PCB Assembly 10W 56mm Aluminum Plate

Substrate: FR-4, CEM-3, Aluminum

Layers: 1-22 layers

Maximum panel: 1550mm*800mm

Copper Thickness: 0.5oz, 1oz, 2oz, 3oz, 4oz

Dielectric thickness: 0.05mm, 0.075mm, 0.1mm, 0.15mm, 0.2mm

Core thickness: 0.4mm, 0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm, 3.0mm and 3.2mm

Plate thickness: 0.4mm - 4.0mm

Thickness tolerance: +/-10%

Aluminum machining: provide drilling, tapping, milling, routing, punching, folding

Sensitive hole: 0.2 mm

Maximum working voltage: 2.5kVDC (0.075mm dielectric), 3.75kVDC (0.15mm dielectric)

Minimum track width: 0.2mm (8mil)

Minimum track clearance: 0.2mm (8mil)

Minimum SMD pad pitch: 0.2mm (8mil)

Surface treatment: HASL lead-free, immersion gold, immersion silver

Solder mask color: green, blue, etc.

Legend Color: Black, White, etc.

Electronic testing: yes

Certificate: UL/ROHS/ISO9001

Name: AC220V LED Panel PCB Assembly

Substrate: FR-4, CEM-3, Aluminum

Layers: 1-22 layers

Maximum panel: 1550mm*800mm

Copper Thickness: 0.5oz, 1oz, 2oz, 3oz, 4oz

Dielectric thickness: 0.05mm, 0.075mm, 0.1mm, 0.15mm, 0.2mm

Core thickness: 0.4mm, 0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm, 3.0mm and 3.2mm

Plate thickness: 0.4mm - 4.0mm

Thickness tolerance: +/-10%

Aluminum machining: provide drilling, tapping, milling, routing, punching, folding

Sensitive hole: 0.2 mm

Maximum working voltage: 2.5kVDC (0.075mm dielectric), 3.75kVDC (0.15mm dielectric)

Minimum track width: 0.2mm (8mil)

Minimum track clearance: 0.2mm (8mil)

Minimum SMD pad pitch: 0.2mm (8mil)

Surface treatment: HASL lead-free, immersion gold, immersion silver

Solder mask color: green, blue, etc.

Legend Color: Black, White, etc.

Electronic testing: yes

Certificate: UL/ROHS/ISO9001

PCB Assembly SMD 2835 Round Board

Name: PCB Assembly SMD 2835 Round Board

Number of layers: 1 layer

PCB thickness: 1.0-2.0mm

Copper Thickness: 1oz-2oz

Surface: HAL/OSP/LF-HAL

Thermal conductivity: 1.0-3 0w/mk

Solder Mask Type: Liquid Photosensitive Solder Marker

Accepting OEM orders for SMT and A/I assembly projects

SMD 2835 LED Light Module PCB Assembly

Name: SMD 2835 LED Light Module PCB Assembly

Number of layers: 1 layer

PCB thickness: 1.0-2.0mm

Copper Thickness: 1oz-2oz

Surface: HAL/OSP/LF-HAL

Thermal conductivity: 1.0-3 0w/mk

Solder Mask Type: Liquid Photosensitive Solder Marker

Accepting OEM orders for SMT and A/I assembly projects

Prototype PCB Assembly SMD Street Light LED

Name: Prototype PCB Assembly SMD Street Light LED

Material: CEM1, CEM3

Layers: 1~24 layers

Maximum / panel size: 541*647mm (special can be made 950mm)

Aspect Ratio: Minimum 1:8

Ring: Min. 0.1mm

Finished hole size: PTH ±0.003'', NPTH ±0.002"

Impedance control: ±5%

Solder Mask Registration: ±0.003"

Layer-to-layer registration: ±0.003"

PCB Project: PCB OEM/PCB Design/PCB Assembly

Surface treatment: HASL, OSP, ENIG, gold plated

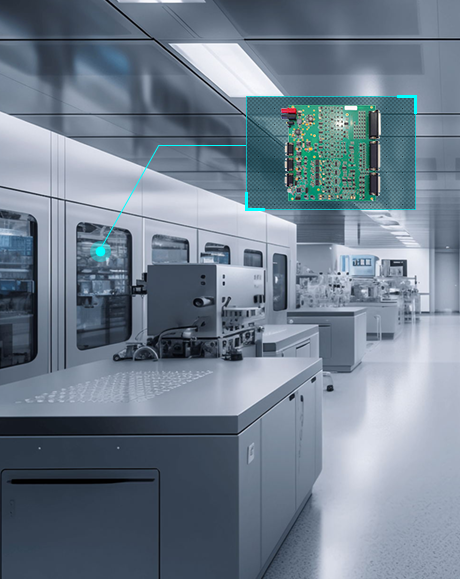

Single Sided Aluminum Prototype PCB Assembly

Name: Single Sided Aluminum Prototype PCB Assembly

Layers: 1-20

Plate thickness: 0.20mm-4.0mm

Copper Thickness: 17.5um-175um (0.5oz-5oz)

Solder mask color: red, black, blue, green, yellow

Stencil cleaning frequency: 1 time/5 to 10 sheets

Surface treatment: spray tin, lead-free spray tin, OSP, gold plating, immersion gold

Minimum trace width: 0.15mm

minute. Line spacing: 3 mil (0.075 mm)

Minimum space width: 0.15mm

Substrate: FR4/Aluminum

Minimum drilling diameter: 0.2mm

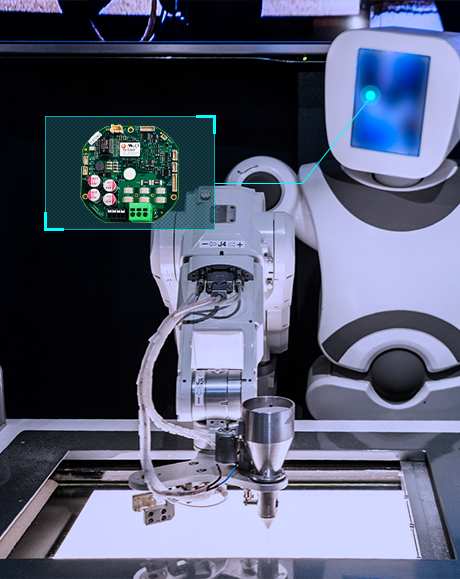

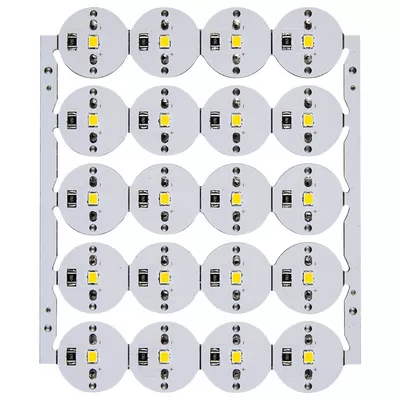

Automotive Lighting LED PCB Assembly

Name: SMD LED chip PCB assembly

Material: Aluminum base

Voltage: 160-280V

Wattage: 3W

Chip: SMD-2835/5730/4014

Number of LEDs: 12

Diameter: 31mm

Temperature: 2700-6500k

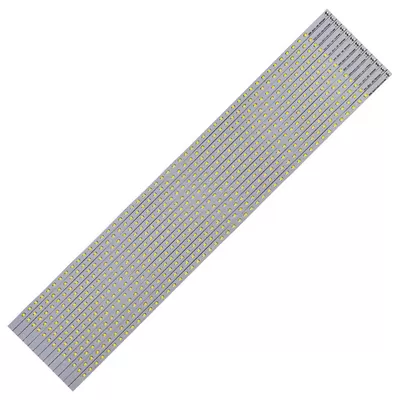

T8/T5/LED slats/line lights SMT processing

Name: T8/T5/LED slat/line light SMT processing

Substrate Material: Aluminum

Copper thickness: 1.0-2.0mm

Copper Thickness: 0.5-6oz

Thermal conductivity: 1.0-3.0W/mk

Breakdown voltage: 2-4KV

Lead: SMD 2835

Flammability: 94V0

Solder mask: white

Silkscreen: black

Working temperature: -25-75℃

Service: OEM&ODM

Surface Treatment: HAL/OSP/Immersion Gold/Gold/Tin/Immersion Tin

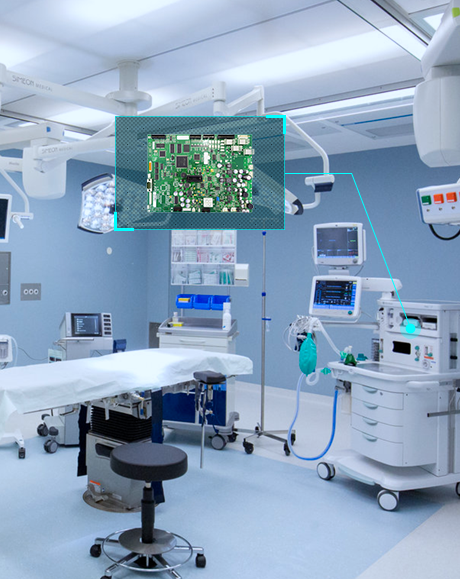

- PCB Assembly Equipment

- PCB Assembly Capability

Automatic solder paste printing machine

AOI Optical Inspection

SMT high-speed placement machine

Nitrogen reflow soldering

x-ray

Three anti-paint spraying machine

SPI Solder Paste Thickness Tester

Automatic wave soldering machine

first article inspection

| SMT capacity: 19 million points/day | ||

| Testing Equipment | X-RAY Nondestructive Tester, First Piece Tester, AOI Automatic Optical Tester, ICT Tester, BGA Rework Station | |

| Placement speed | Chip placement speed (at best conditions) 0.036 S/piece | |

| Mounted Component Specifications | Pasteable smallest package | |

| Minimum device accuracy | ||

| IC type chip accuracy | ||

| Mounted PCB Specifications | Substrate size | |

| Substrate thickness | ||

| throw rate | 1. Resistance-capacitance ratio 0.3% | |

| 2. IC type without throwing material | ||

| Board Type | POP/common board/FPC/rigid-flex board/metal substrate | |

| DIP daily production capacity | ||

| DIP plug-in production line | 50000 points/day | |

| DIP post welding production line | 20000 points/day | |

| DIP test production line | 50000pcs PCBA/day | |

| Assembly processing capability | ||

| The company has more than 10 advanced assembly production lines, dust-free and anti-static air-conditioning workshop, TP dust-free workshop, equipped with aging room, test room, functional test isolation room, advanced and perfect equipment, can carry out various product assembly, packaging, testing, Aging, etc. production. Monthly production capacity can reach 150,000 to 300,000 sets/month | ||

| PCBA processing capability | ||

| project | Mass processing capability | Small batch processing capability |

| Number of layers (max) | 2-18 | 20-30 |

| Plate type | FR-4, Ceramic Sheet, Aluminum Base Sheet PTFE, Halogen Free Sheet, High Tg Sheet | PTFE, PPO, PPE |

| Rogers,etc Teflon | E-65, ect | |

| Sheet mixing | 4 layers - 6 layers | 6th floor - 8th floor |

| biggest size | 610mm X 1100mm | / |

| Dimensional Accuracy | ±0.13mm | ±0.10mm |

| Plate thickness range | 0.2mm--6.00mm | 0.2mm--8.00mm |

| Thickness tolerance ( t≥0.8mm) | ±8% | ±5% |

| Thickness tolerance (t<0.8mm) | ±10% | ±8% |

| Media thickness | 0.076mm--6.00mm | 0.076mm--0.100mm |

| Minimum line width | 0.10mm | 0.075mm |

| Minimum spacing | 0.10mm | 0.075mm |

| Outer copper thickness | 8.75um--175um | 8.75um--280um |

| Inner layer copper thickness | 17.5um--175um | 0.15mm--0.25mm |

| Drilling hole diameter (mechanical drill) | 0.25mm--6.00mm | 0.15mm--0.25mm |

| Hole diameter (mechanical drill) | 0.20mm--6.00mm | 0.10mm--0.20mm |

| Hole Tolerance (Mechanical Drill) | 0.05mm | / |

| Hole tolerance (mechanical drill) | 0.075mm | 0.050mm |

| Laser Drilling Aperture | 0.10mm | 0.075mm |

| Plate thickness aperture ratio | 10:1 | 12:1 |

| Solder mask type | Photosensitive green, yellow, black, purple, blue, ink | / |

| Minimum Solder Mask Bridge Width | 0.10mm | 0.075mm |

| Minimum Solder Mask Isolation Ring | 0.05mm | 0.025mm |

| Plug hole diameter | 0.25mm--0.60mm | 0.60mm-0.80mm |

| Impedance tolerance | ±10% | ±5% |

| Surface treatment type | Hot air leveling, chemical nickel gold, immersion silver, electroplated nickel gold, chemical immersion tin, gold finger card board | Immersion Tin, OSP |

The LED PCB circuit is printed on an aluminum plate with good thermal conductivity, and then electronic components are soldered to it.