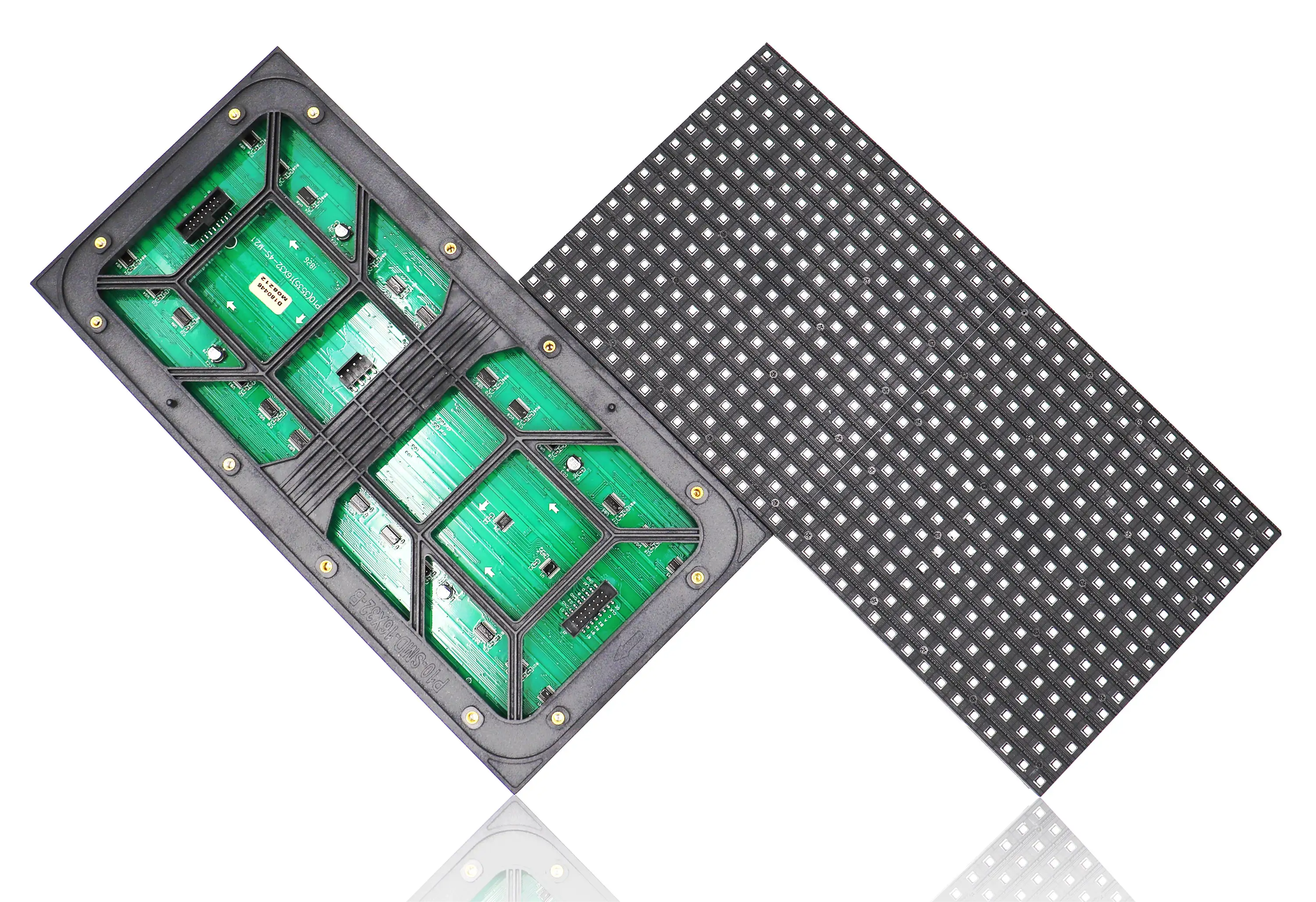

AC220V LED Panel PCB Assembly

Name: AC220V LED Panel PCB Assembly

Substrate: FR-4, CEM-3, Aluminum

Layers: 1-22 layers

Maximum panel: 1550mm*800mm

Copper Thickness: 0.5oz, 1oz, 2oz, 3oz, 4oz

Dielectric thickness: 0.05mm, 0.075mm, 0.1mm, 0.15mm, 0.2mm

Core thickness: 0.4mm, 0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm, 3.0mm and 3.2mm

Plate thickness: 0.4mm - 4.0mm

Thickness tolerance: +/-10%

Aluminum machining: provide drilling, tapping, milling, routing, punching, folding

Sensitive hole: 0.2 mm

Maximum working voltage: 2.5kVDC (0.075mm dielectric), 3.75kVDC (0.15mm dielectric)

Minimum track width: 0.2mm (8mil)

Minimum track clearance: 0.2mm (8mil)

Minimum SMD pad pitch: 0.2mm (8mil)

Surface treatment: HASL lead-free, immersion gold, immersion silver

Solder mask color: green, blue, etc.

Legend Color: Black, White, etc.

Electronic testing: yes

Certificate: UL/ROHS/ISO9001

Advantages of LEDs

1. Area extensibility. The large LCD area is difficult to achieve seamless splicing. The LED display can be extended arbitrarily and seamlessly spliced. the

2. The luminous flux of the LCD plasma screen decays quickly. Generally, it needs to be replaced after about one and a half years of operation, but the LED display screen is no problem for at least five years under the same operating conditions.

3. The LED flashing machine can use interactive technology to enhance the interaction between the flashing machine as an advertising medium and the advertising audience, such as customizing the touch screen, realizing cloud technology broadcast control management, etc.

4. In terms of display effect, the high brightness, wide viewing angle and good color reproduction ability of LED display are also better than LCD screen. LED screen refreshers are generally used in airports, shopping malls, hotels, high-speed rail, subways, cinemas, exhibitions, office buildings, etc. The target customers have strong spending power and have huge advertising value.

LED display performance is superior:

(1) The luminous brightness is strong, and when the sunlight directly hits the screen surface within the viewing distance, the display content is clearly visible. Super grayscale control has 1024-4096 grayscale control, and the display color is above 16.7M. The color is clear and vivid, and the three-dimensional effect is strong.

(2) Static scanning technology, using static latch scanning mode, high-power drive, fully guarantees the luminous brightness.

(3) Automatic brightness adjustment With automatic brightness adjustment function, the best playback effect can be obtained in different brightness environments.

(4) Fully adopt imported large-scale integrated circuits, the reliability is greatly improved, and it is convenient for debugging and maintenance.

(5) Advanced digital video processing, technology distributed scanning, BSV liquid crystal splicing technology high-definition display, modular design/constant current static drive, automatic brightness adjustment, super bright solid color pixels, clear image, no jitter and ghosting, Eliminate distortion. Video, animation, chart, text, picture and other information display, network display, remote control.

The color of the LED is different from the material used to manufacture the LED, which can produce photons with different energies, so that the wavelength of the light emitted by the LED can be controlled, that is, the spectrum or color.

1. The material used in the first LED in history is arsenic (As) gallium (Ga), its forward PN junction voltage drop (VF, can be understood as lighting or working voltage) is 1.424V, and the light emitted is infrared spectrum .

2. Another commonly used LED material is gallium (P) phosphide (Ga), its forward PN junction voltage drop is 2.261V, and the light emitted is green.

3. Based on these two materials, the early LED industry used the GaAs1-xPx material structure, which can theoretically produce LEDs with any wavelength from infrared light to green light. The subscript X represents the percentage of phosphorus replaced by arsenic. Generally, the wavelength and color of the LED can be determined by the voltage drop of the PN junction. The typical ones are red LED of GaAs0.6P0.4, orange LED of GaAs0.35P0.65, yellow LED of GaAs0.14P0.86, etc. Because gallium, arsenic, and phosphorus are used in the manufacture, these LEDs are commonly known as three-element light-emitting tubes. GaN (gallium nitride) blue LEDs, GaP green LEDs and GaAs infrared LEDs are called two-element light-emitting tubes. At present, the latest technology is a four-element LED made of AlGaInN four-element material mixed with four elements of aluminum (Al), calcium (Ca), indium (In) and nitrogen (N), which can cover all visible light and some ultraviolet light. The spectral range of light.

4. The measurement units of luminous intensity include illuminance unit (lux Lux), luminous flux unit (lumen Lumen), luminous intensity unit (candle power)

5. 1CD (candlelight) refers to the luminous intensity of a completely radiating object per sixtieth square centimeter at the freezing point of platinum. (formerly refers to a whale oil candle with a diameter of 2.2 cm and a mass of 75.5 grams, burning 7.78 grams per hour, a flame height of 4.5 cm, and the luminous intensity along the horizontal direction)

6. 1Lm (lumen) refers to the luminous flux irradiated by 1 CD candlelight on a plane with a distance of 1 cm and an area of 1 square cm.

7. 1Lux (lux) refers to the illuminance at which 1L of luminous flux is evenly distributed on an area of 1 square meter.

8. Generally, active illuminants use the unit of luminous intensity, candlelight CD, such as incandescent lamps, LEDs, etc.; reflective or penetrating objects use the unit of luminous flux, L, such as LCD projectors, etc.; and the unit of illuminance, Lux, is generally used in photography and other fields . The three units of measurement are numerically equivalent, but need to be understood from different perspectives. For example: if the brightness (luminous flux) of an LCD projector is 1600 lumens, and the size of its projection onto a fully reflective screen is 60 inches (1 square meter), its illuminance is 1600 lux, assuming that its light outlet is 1 cm, and the area of the light outlet is 1 square centimeter, then the luminous intensity of the light outlet is 1600CD. However, due to the loss of light transmission, loss of reflection or light-transmitting film, and uneven distribution of light, the brightness of a real LCD projector will be greatly reduced. Generally, an efficiency of 50% is good.

9. In actual use, light intensity calculations often use data units that are easier to survey and map or change directions. For active illuminants such as LED displays, CD/square meter is generally used as the unit of luminous intensity, and the viewing angle is used as an auxiliary parameter, which is equivalent to the illuminance unit lux on the surface of the screen; this value is compared with the effective display area of the screen. Multiplied together, the luminous intensity of the entire screen at the best viewing angle is obtained. Assuming that the luminous intensity of each pixel in the screen is constant in the corresponding space, this value can be considered as the luminous flux of the entire screen. Generally, the outdoor LED display must reach a brightness of more than 4000CD/square meter to have an ideal display effect under sunlight. For ordinary indoor LEDs, the maximum brightness is about 700-2000 CD/square meter. The luminous intensity of a single LED is in CD, and it is equipped with viewing angle parameters. The luminous intensity has nothing to do with the color of the LED. The luminous intensity of a single tube varies from a few mCDs to five thousand mCDs. The luminous intensity given by the LED manufacturer refers to the point where the LED lights up at a current of 20mA, the best viewing angle and the center position with the highest luminous intensity. The shape of the top lens and the position of the LED chip from the top lens when packaging the LED determine the LED viewing angle and light intensity distribution. Generally speaking, the larger the viewing angle of the same LED, the smaller the maximum luminous intensity, but the accumulated luminous flux on the entire three-dimensional hemisphere remains unchanged.

10. When multiple LEDs are arranged closely and regularly, their luminous spherical surfaces overlap with each other, resulting in a relatively uniform distribution of luminous intensity across the entire luminous plane. When calculating the luminous intensity of the display screen, it is necessary to multiply the maximum point luminous intensity value provided by the manufacturer by 30% to 90% according to the LED viewing angle and the LED emission density, as the average luminous intensity of a single tube.

11. Generally, the luminous life of LEDs is very long, and manufacturers generally mark it as more than 100,000 hours. In fact, attention should also be paid to the brightness decay cycle of LEDs. It's only half of the original. The brightness attenuation period has a lot to do with the material technology of LED production. Generally, four-element LEDs with slower brightness attenuation should be selected when economic conditions permit.

12. White is a mixture of red, green and blue according to the brightness ratio. When the brightness of green in the light is 69%, the brightness of red is 21%, and the brightness of blue is 10%, the human eye feels pure white after color mixing . However, the chromaticity coordinates of the red, green and blue colors of LED cannot achieve the effect of the full spectrum due to the process and other reasons, and controlling the brightness of the primary colors including the deviation of the primary colors to obtain white light is called color matching.

13. Before color matching for full-color LED displays, in order to achieve the best brightness and the lowest cost, try to choose LED devices with a ratio of 3:6:1 to form pixels.

14. White balance requires that the three primary colors synthesized under the same gray value are still pure white.

15. Primary color, base color.

16. Primary colors refer to the basic colors that can be synthesized into various colors. The primary colors in shaded light are red, green, and blue. If the primary color deviates, the area where the color can be synthesized will decrease, and the triangles in the spectral table will shrink. From a visual point of view, the color will not only deviate, but also reduce the richness.

Future trends

The LED display industry has rapidly flourished and formed a new stage of development. Specifically divided into 3 stages:

1. The utility model stage of LED display: LED display has the characteristics of environmental protection, high brightness, high definition, and high reliability. In the previous stage, the LED display market only met people's needs, but in the LED display The screen products can't meet the requirements, and the quality is not good enough.

With the development of LED display screens, LED products now have a new breakthrough. At least it has improved and improved compared to the previous stage. It has also developed a series of products that are completely different from traditional light source applications and will become popular. There will be a bigger and wider development space for LED display screens. The LED display is not only a beautification function, but its changeability makes it more suitable for people's work and life. Now manufacturers are fighting for advantages in design applications and technology research and development.

2. LED display intelligent control stage: With the continuous progress and development of LED display technology, LED, as a semiconductor industry, will also catch this high-speed train and give full play to its high controllability characteristics. From homes to office buildings, from roads to tunnels, from cars to walks, from indoors to outdoors, the LED display system with intelligent control will bring a higher level of service to human beings. The LED display industry will also go from making products, to designing products, to providing overall solutions.

3. The acceptance stage of LED display replacement: Since the characteristics of LED display products are mainly reflected in high light efficiency (low energy consumption) and long life, this stage is the initial stage of LED display development. There seems to be a certain comparison. Of course, customers have an acceptance process, a transition and acceptance of customers' usage habits and appearance. Let customers understand the characteristics of LED display products, and choose one with the characteristics of power saving and longevity. In this way, customers are easy to accept its relatively high price, especially in commercial occasions, not to mention that customers are now second in price, mainly in terms of quality. Therefore, manufacturers are now fighting for quality and price advantages. The display effect of the screen is more demanding. When the refresh rate of the display screen is insufficient, horizontal scanning lines will appear. It is necessary to improve the scan output technology of the LED display control system so that the refresh rate of the LED display screen is higher than the shutter speed of ordinary cameras. , Eliminate scanning horizontal lines under camera shooting.

To sum up, LED display is in a stage of rapid development and growth. I believe that in the near future, LED display will be used in more fields, and at the same time, various LED displays will emerge in the market. The new products of LED screens bring consumers better, more convenient and more energy-saving LED displays. And the AC220V LED panel and PCB assembly produced by Kingford have the characteristics of high quality and excellent cost performance, and it is a supplier with excellent qualifications

Name: AC220V LED Panel PCB Assembly

Substrate: FR-4, CEM-3, Aluminum

Layers: 1-22 layers

Maximum panel: 1550mm*800mm

Copper Thickness: 0.5oz, 1oz, 2oz, 3oz, 4oz

Dielectric thickness: 0.05mm, 0.075mm, 0.1mm, 0.15mm, 0.2mm

Core thickness: 0.4mm, 0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm, 3.0mm and 3.2mm

Plate thickness: 0.4mm - 4.0mm

Thickness tolerance: +/-10%

Aluminum machining: provide drilling, tapping, milling, routing, punching, folding

Sensitive hole: 0.2 mm

Maximum working voltage: 2.5kVDC (0.075mm dielectric), 3.75kVDC (0.15mm dielectric)

Minimum track width: 0.2mm (8mil)

Minimum track clearance: 0.2mm (8mil)

Minimum SMD pad pitch: 0.2mm (8mil)

Surface treatment: HASL lead-free, immersion gold, immersion silver

Solder mask color: green, blue, etc.

Legend Color: Black, White, etc.

Electronic testing: yes

Certificate: UL/ROHS/ISO9001