Why are PCB boards mostly green?

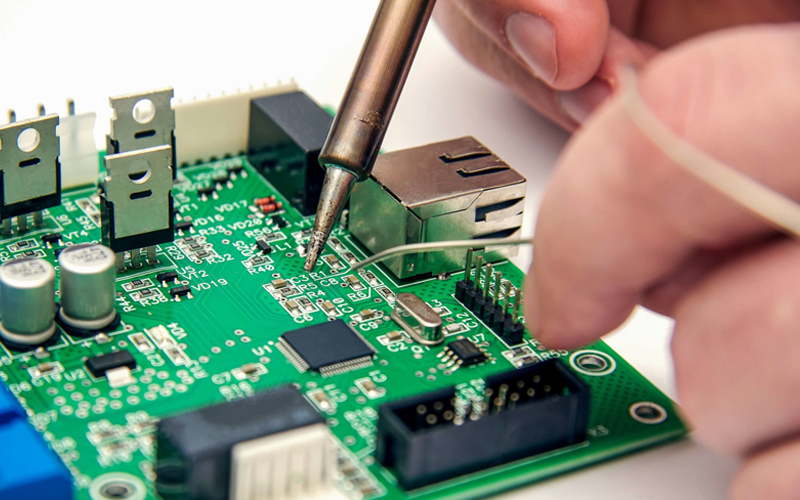

Nowadays, circuit boards have been widely used in the field of modern information technology and modern industrial production. They can make circuits miniaturized and intuitive, and play an important role in the mass production of fixed circuits and the optimization of the layout of electrical appliances. According to different design principles, circuit boards can be divided into single panel, multilayer board, flexible board, rigid board and other types. However, have you found that most of the circuit boards on the market are green, but other colors are rare? Why on earth? Next, let's popularize a wave of knowledge about circuit boards~

We can see that most PCB boards are green because the ink for PCB boards is green. The main function of the ink is to protect the PCB surface, form a protective layer with a certain thickness, and block the contact between copper and air. In fact, PCB boards are also black, white, red, blue, yellow, etc. Why are PCB boards mostly green? Here's why:

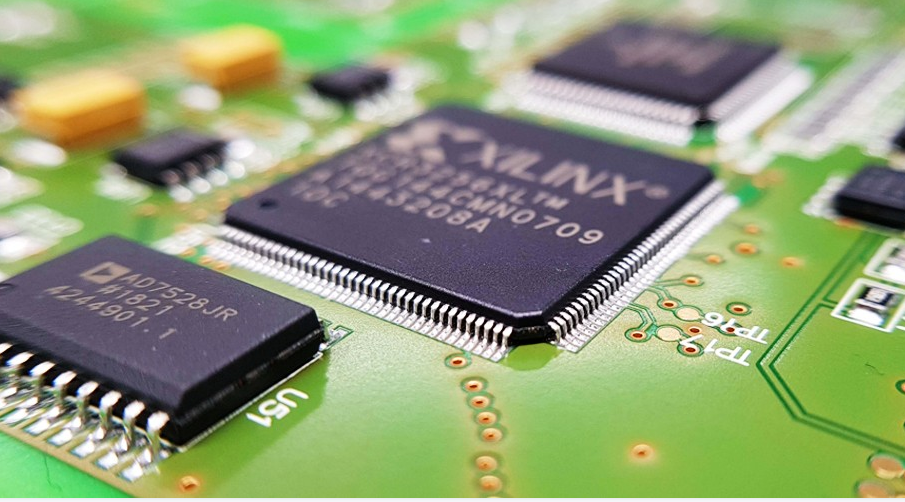

1. Manufacturing process:

Green ink can achieve smaller error, smaller area and higher precision

2. Cost control:

Because green ink has more advantages in process processing, more and more electronic engineers are willing to choose green ink, which will lead to more green ink reserves in factories. With large procurement and shipment, the cost can be naturally reduced. Therefore, the cost of using green ink for PCB is the lowest.

Inks of other colors, such as black ink, are difficult to manufacture and use because their surface routing is almost completely covered, and black PCB is the most difficult to use. Therefore, the yield is relatively lower than PCB boards of other colors, and the cost is relatively high.

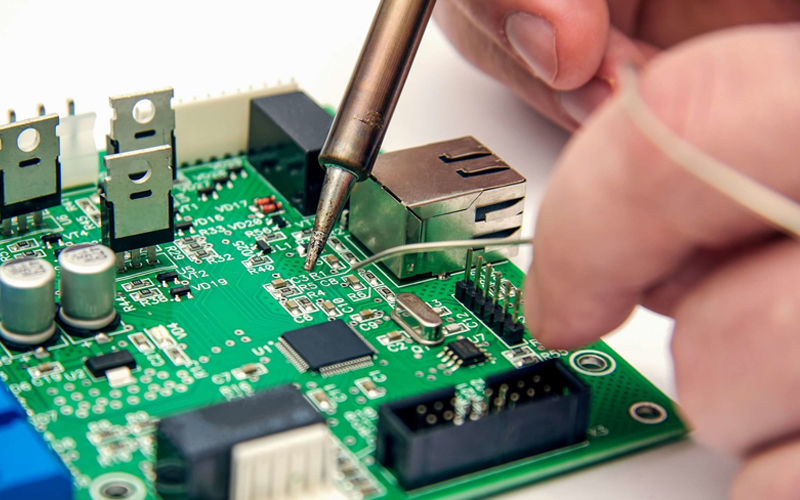

3. Personnel factors:

Green ink is selected. Because green is less irritating to the eyes, it is not easy for production and maintenance personnel to be tired when staring at PCB boards for a long time.

So we can see that there are three reasons why most PCB boards are green. The first is due to process considerations, the second is due to cost considerations, and the third is due to staff considerations. Of course, special colors can also be selected for special scenarios. For example, LED boards are suitable for white ink, which is conducive to the heat dissipation of PCB boards. So we should choose the color of ink according to our actual needs.

Generally speaking, a complete circuit board is composed of bonding pads, vias, solder mask, silk screen layer, copper wire and other components. The bottom layer with color on the circuit board surface is the solder mask coated with solder mask ink. The color of the solder mask layer mainly depends on the color of the solder mask ink. In fact, the solder mask ink on the market is not only limited to green, but also red, blue, purple, black, yellow and other colors. However, green is the most common, mainly because the use of green solder mask ink has the following advantages.

L Better visual effect in yellow light room

When the circuit board is used in the production and processing of electronic products, some processes need to go through the yellow light room. According to the optical law, green circuit boards have better visual effect in the yellow light room, and it is easier to view the production of electronic products.

L Convenient for optical positioning and correction

The production process of the circuit board itself includes the STM welding process, which requires tin coating and the final AOI verification. These processes require optical positioning calibration, and the green background is better for instrument identification.

L It is beneficial for workers to observe the circuit board

It is believed that everyone knows that green is the most eye friendly color. Therefore, considering that part of the production process and inspection process of the circuit board need to be completed manually, using green as the background color of the circuit board can reduce the damage of strong light to workers' eyes.

L Environmental protection and low cost

Because the circuit board needs to be recycled at high temperature when it is discarded, and the green solder proof ink will not release toxic gas, so recycling is more environmentally friendly. Thanks to the above advantages, the adoption rate of green solder proof ink is the highest and the production process is the most mature. Therefore, the cost of using green solder proof ink to produce circuit boards is lower.