With the continuous development of science and technology, electronic products are gradually becoming shorter, smaller, lighter and thinner, and the application of FPC is becoming more and more extensive, but many friends still do not know some specific basic knowledge of FPC. Let me tell you the situation in detail.

Basic knowledge of fpc

1. What is fpc

FPC is the abbreviation of Flexible Printed Circuit, also known as flexible PCB, flexible printed circuit board, flexible PCB, referred to as soft board or FPC, with the characteristics of high wiring density, light weight and thin thickness. Mainly used in mobile phones, notebook computers, PDAs, digital cameras, LCM and many other products.

FPC flexible printed circuit is a highly reliable and excellent flexible printed circuit made of polyimide or polyester film as the base material.

According to the combination of substrate and copper foil, flexible PCBs can be divided into two categories: flexible boards with glue and flexible boards without glue.

Among them, the price of the non-adhesive flexible board is much higher than that of the glued flexible board, but its flexibility, the bonding force between the copper foil and the substrate, and the flatness of the pad are also better than those of the glued flexible board. Therefore, it is generally only used in those occasions with high requirements, such as: COF (CHIP ON FLEX, a bare chip mounted on a flexible board, which requires a high level of pad flatness) and so on.

Due to its high price, most of the flexible boards currently used in the market are still flexible boards with glue.

A flexible board with glue. Since the flexible board is mainly used in the occasions that need to be bent, if the design or process is unreasonable, it is easy to produce defects such as micro-cracks and open welding. The following is about the structure of the flexible PCB and its special requirements in design and process.

Introduction to the basic knowledge of FPC soft board

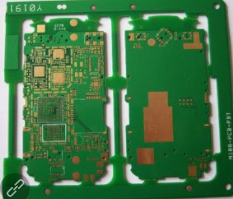

2. The structure of the flexible board

According to the number of layers of conductive copper foil, it is divided into single-layer board, double-layer board, multi-layer board, double-sided board, etc. Structure of single-layer board: The flexible board of this structure is the simplest structure of the flexible board. Usually the base material + transparent glue + copper foil is a set of purchased raw materials, and the protective film + transparent glue is another purchased raw material. First, the copper foil needs to be etched and other processes to obtain the required circuits, and the protective film needs to be drilled to expose the corresponding pads.

After cleaning, use the rolling method to combine the two. Then, gold or tin is plated on the exposed pad part for protection. In this way, the big board is ready. Generally, small circuit boards of corresponding shapes are also punched. There are also solder masks printed directly on the copper foil without a protective film, so the cost will be lower, but the mechanical strength of the circuit board will be worse.

Unless the strength requirements are not high but the price needs to be as low as possible, it is best to apply a protective film. Structure of double-layer board: When the circuit of the circuit is too complicated, the single-layer board cannot be routed, or copper foil is required for grounding shielding, it is necessary to use a double-layer board or even a multi-layer board. The most typical difference between a multi-layer board and a single-layer board is the addition of a via structure to connect each layer of copper foil.

The first processing technology of general substrate + transparent glue + copper foil is to make vias. First drill holes on the substrate and copper foil, and after cleaning, plated with a certain thickness of copper, the vias are ready. The subsequent production process is almost the same as that of the single-layer board. Double-sided structure: There are pads on both sides of the double-sided board, which are mainly used for connection with other PCB circuit boards.

Although it is similar in structure to a single-layer board, the manufacturing process is very different. Its raw materials are copper foil, protective film + transparent glue. First, drill holes on the protective film according to the requirements of the pad position, then paste the copper foil, corrode the pads and leads, and then paste another protective film with the drilled holes.

3. FPC product features:

1. It can be bent, folded and rolled freely, and can be moved and stretched freely in three-dimensional space.

2. The heat dissipation performance is good, and the F-PC can be used to reduce the size.

3. Realize light weight, miniaturization and thinning, so as to achieve the integration of component device and wire connection.

4. Application areas

FPC application fields MP3, MP4 players, portable CD players, home VCD, DVD, digital cameras, mobile phones and mobile phone batteries, medical, automotive and aerospace fields FPC has become an important variety of epoxy copper clad laminates The flexible copper clad laminate (FPC) of the base material is more and more widely used due to its special functions, and is becoming an important variety of epoxy resin-based copper clad laminates.

However, our country started late and has to catch up. Epoxy flexible PCB have experienced more than 30 years of development since their industrial production. Since the 1970s, it has entered a real industrialized mass production. Until the late 1980s, due to the advent and application of a new type of polyimide film material, flexible PCB made FPC appear adhesive-free. FPC (generally referred to as "two-layer FPC").

In the 1990s, photosensitive cover films corresponding to high-density PCB were developed in the world, which made a great change in the design of FPC. Due to the opening of new application fields, the concept of its product form has undergone a lot of changes, and it has been extended to a larger range including substrates for TAB and COB.

The high-density FPC that emerged in the second half of the 1990s began to enter large-scale industrial production. Its circuit patterns are rapidly developing to a finer level, and the market demand for high-density FPC is also growing rapidly.

The above is the "basic knowledge of FPC soft board" compiled by the editor. I hope it will be helpful to everyone. If there is any unclear place, please contact our customer service to answer it for you.