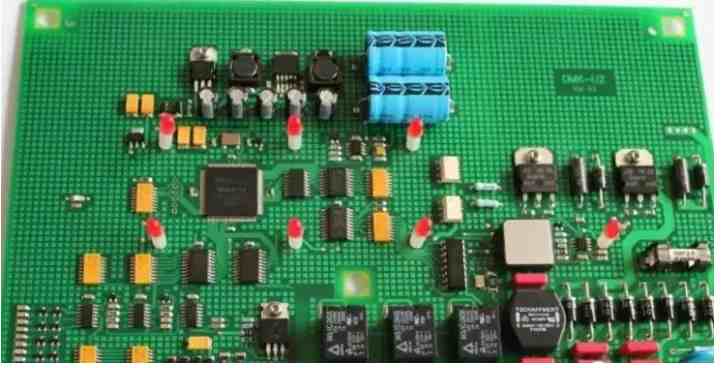

Summary Of The Causes Of Serious Heating Of PCB Board

In integrated circuits, too high a temperature can have a negative impact on the function, the components, and the board itself. Next, PCBA processing manufacturer kinhford Electronics introduces what are the reasons for the serious heating of PCB board?

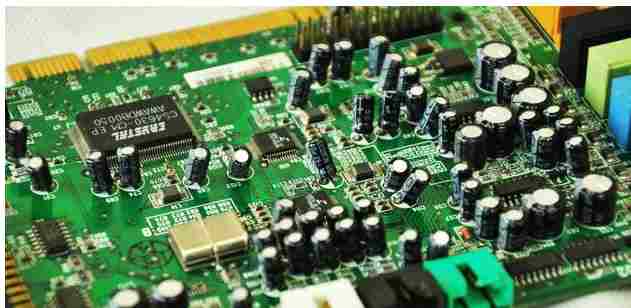

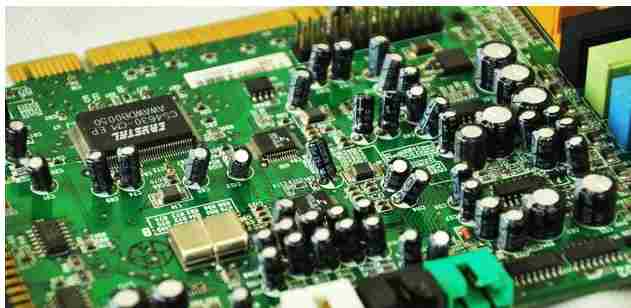

Component Placement Is Incorrect

Some high-power devices need to reserve natural ventilation or forced ventilation for heat dissipation. If there is no proper airflow heat dissipation, the PCB will accumulate most of the heat, resulting in an increase in temperature, which will lead to reduced circuit performance or damage. It should be noted that the sensitive element should not be placed near the component with large heat output; With proper heat dissipation and natural or forced cooling, the temperature can be kept within a safe range.

Environmental and external thermal factorsWhen the PCB is used in an extreme temperature environment, if the temperature conditions of the target environment are not considered in the design, it may lead to excessive pressure on electronic components; Typically, electronic component manufacturers will provide specifications for a specific temperature range.

Wrong Parts And Material Selection

In the process of selecting materials for electronic components, not following the recommended guidelines may lead to heat dissipation problems. When selecting an electronic component, it is important to look at the detailed data and consider all relevant information related to power consumption, thermal resistance, temperature limitation and cooling technology. In addition, a quick power calculation is performed on the resistor to ensure that the appropriate power rating for the application is selected. Another problem is the choice of PCB dielectric materials. The printed circuit board itself must be able to withstand the worst thermal conditions.

PCB Design And Manufacturing Defect

Poor layout and manufacturing processes can lead to PCB heat dissipation problems. Improper welding may hinder heat dissipation, and insufficient wiring width or copper area may also lead to higher temperatures. To prevent heat dissipation, designers must reduce heat dissipation when natural heat dissipation is insufficient and use other heat dissipation techniques; For thermal optimization design, attention should be paid to component specifications, PCB layout, PCB dielectric materials and environmental conditions.

Shenzhen Kingford Technology Co., Ltd. specializes in providing integrated PCBA electronic manufacturing services, including upstream electronic component procurement to PCB production and processing, SMT patches, DIP plug-ins, PCBA testing, finished product assembly and other one-stop services.

The company gives full play to its competitive advantages in scale procurement and quality control, and has signed long-term cooperation agreements with many electronic component manufacturers at home and abroad and around the world to ensure the quality and stable supply of raw materials, and transfer the benefits to customers.

Long-term maintenance of IC, resistors, capacitors, inductors, audiodes and other components procurement advantages, can greatly save customers' inventory costs, improve production turnover efficiency, save time. Currently for the United States, Britain, Japan, Russia, France, Canada, Australia, Romania, Switzerland and other countries and regions to provide PCBA processing services.