What Is The Meaning Of Through Hole Plug Oil In PCB Process?

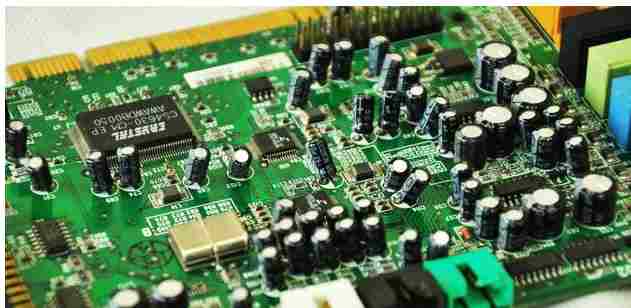

The three common ways of PCB board for through hole treatment are through hole opening window, through hole cover oil and through hole plug oil, and then PCB board factory Shenzhen Kingford Technology Co., Ltd. will introduce what is the meaning of through hole plug oil in PCB boardprocess.

First, Through the hole plug oil is to guide through the hole with ink inside the hole to make the plug hole, emphasizing the quality and tightness of the plug hole. The treatment and inspection standard of the plug oil is that it is not transparent, and it must be covered with ink and blocked.

Secondly, the hole can not appear yellow phenomenon, and do not touch tin.

Through the hole plug oil process is an important supplement to through the hole cover oil, generally high-quality PCB board will require to make through the hole plug oil. Through the hole plug oil first through the hole full hole plug ink, after the plug hole can not be transparent to block the hole, so that the ink on the solder resistance ring will not flow into the hole, so as to achieve the effect of no yellow through the hole.

The smaller the hole, the easier it is to plug, and the hole of the oil is not too large, the maximum is 0.5mm, so it is recommended to cover the hole oil for holes larger than 0.5mm.

The pores mentioned above are usually used for interlayer conduction. Therefore, in order to avoid short circuit when the board is used, it is usually done to cover the oil, which not only ensures the electrical PCB needs erformance, but also avoids the risk of short circuit with other components during use. Therefore, if someone to pass the hole as a test point or heat dissipation, it will be done to open the window.

Shenzhen Kingford Technology Co., Ltd. is a circuit board manufacturer specializing in printed circuit board manufacturing, 20 years of focus on single, double sided, multi-layer circuit board production. Can provide impedance board, HDI board, blind hole board and other multi-layer PCB board proofing, small batch production business.

Energy production from 2 layers to 14 layers, 14-22 layers can be proofing production.

Minimum line width/spacing: 3mil/3milBGA Spacing :0.20MM Minimum aperture: 0.1mm Size :610mmX1200mm Ink: Japan Tamura, Taiyo, Fudoken; FR4: Sheng Yi, Kingboard, Harbour, Hongren, Guoji, Hezheng, South Asia, (Shengyi S1130/S1141/S1170),Tg130℃/ Tg170℃ T g180℃ and other high TG plates)

High frequency board: Rogers, Taconic, ARLLON; Surface process: spray tin, lead-free spray tin, sinking gold, full plate gold plating, plug gold plating, full plate thick gold, chemical sinking tin (silver), anti-oxidation (OSP) blue, glue, carbon oil

Some high-power devices need to reserve natural ventilation or forced ventilation for heat dissipation. If there is no proper airflow heat dissipation, the PCB will accumulate most of the heat, resulting in an increase in temperature, which will lead to reduced circuit performance or damage. It should be noted that the sensitive element should not be placed near the component with large heat output; With proper heat dissipation and natural or forced cooling, the temperature can be kept within a safe range.

Environmental and external thermal factors

When the PCB is used in an extreme temperature environment, if the temperature conditions of the target environment are not considered in the design, it may lead to excessive pressure on electronic components; Typically, electronic component manufacturers will provide specifications for a specific temperature range. 3. Wrong parts and material selection

In the process of selecting materials for electronic components, not following the recommended guidelines may lead to heat dissipation problems. When selecting an electronic component, it is important to look at the detailed data and consider all relevant information related to power consumption, thermal resistance, temperature limitation and cooling technology. In addition, a quick power calculation is performed on the resistor to ensure that the appropriate power rating for the application is selected. Another problem is the choice of PCB dielectric materials. The printed circuit board itself must be able to withstand the worst thermal conditions.

PCB Design And Manufacturing Defects

Poor layout and manufacturing processes can lead to PCB heat dissipation problems. Improper welding may hinder heat dissipation, and insufficient wiring width or copper area may also lead to higher temperatures. To prevent heat dissipation, designers must reduce heat dissipation when natural heat dissipation is insufficient and use other heat dissipation techniques; For thermal optimization design, attention should be paid to component specifications, PCB layout, PCB dielectric materials and environmental conditions.