The efficiency of PCB boards depends on the number of layers, so the correct selection of PCB layers is crucial. So how to determine the number of layers when PCB design? Next, professional PCB design company electronics to introduce you.

When deciding the number of PCB design layers, the following issues should be taken into account: 1

Where will the PCB be used? PCBS are used in various types of simple to complex electronic devices.

1,The first thing to figure out is whether the application has minimal functionality or complex functionality.

2, the required signal type

The choice of the number of layers also depends on the type of signal they need to transmit, the signal is divided into high frequency, low frequency, ground or power supply, for applications requiring multi-signal processing, you need multi-layer PCB, these circuits may require different grounding and isolation.

3. Through hole type

The choice of through holes is another important factor to consider, if you choose to bury through holes, you may need more internal layers, so the multi-layer needs can be met accordingly

4. Density and number of signal layers required

The PCB layer is also determined based on two important factors: signal layer and pin density. The number of layers in the PCB increases as the pin density decreases. Pin density is 1.0. For example, a pin density of 1 would require 2 signal layers. However, pin density. 0.2 May require 10 layers or more.

5. Number of planes required

The power and ground planes in the PCB help reduce EMI as well as shield the signal layer. Therefore, the choice of layer will again depend on the number of planes required.

6. Manufacturing cost

Although a major requirement, it is one of the determining factors in choosing the number of layers in a 1-40 layer PCB design. The cost of PCB manufacturing depends on the multiple layers. Multilayer PCBS are more expensive than single-layer PCBS, and manufacturing costs will largely depend on the above requirements.

7. Delivery time

Delivery times based on 1-40 layer PCB designs depend on all of the above factors. For example, if your design requires a single layer, the lead time may be less. If you are ordering PCBS for complex industrial electronics, the lead time will increase.

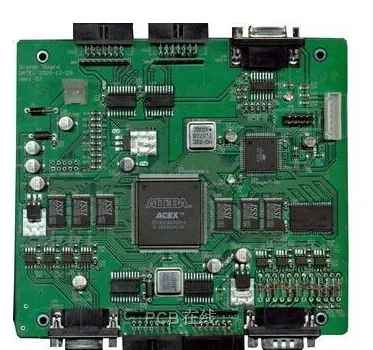

Usually PCB designers will be based on the complexity of the design circuit schematic to determine the design of several layers of board, mainly from the schematic of the core device outlet and the difficulty of the layout of the appliance to decide. If you are unable to make a decision based on the above factors, it is best to discuss it with the manufacturer.

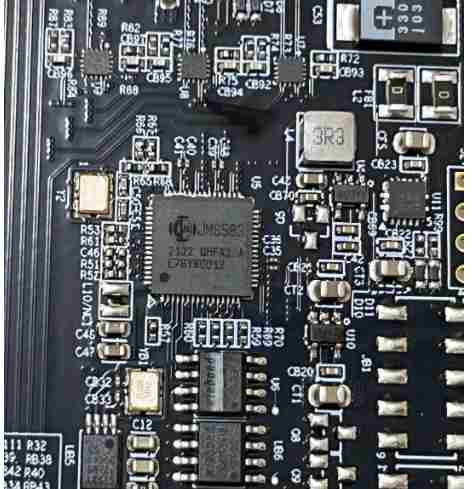

Electronic is a professional engaged in electronic products circuit board design (layout layout design) PCB design company, mainly undertake multi-layer, high-density PCB design drawing board and circuit board design proofing business. With an average of more than 10 years of work experience in PCB design team, can skillfully use the market mainstream PCB design software, professional and efficient communication to ensure PCB design progress, to help you seize the market opportunity one step earlier!