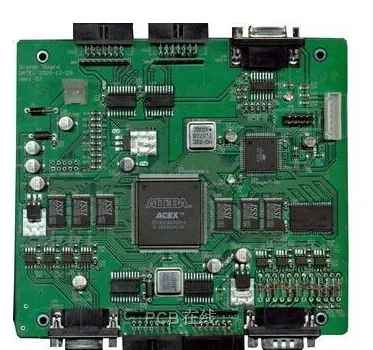

Many friends have questions, why the vast majority of PCB board color is green?

The PCB board color is mostly green

1, green ink is by far the most widely used, the longest use, but also the cheapest on the market, so green is used by a large number of manufacturers as the main color of PCB products.

2, under normal circumstances, in the process of PCB board production, there are several processes that must go through the yellow light room, because the effect of green in the yellow light room is better than other colors. In addition, when SMT welding components, PCB board production must go through the solder paste and patch, and the final AOI verification process, which requires optical positioning calibration, and the board with a green background color has a better identification effect on the instrument.

3, PCB board production is not necessarily green, depending on the designer wants to make it into what color, it is what color. Common PCB board production colors are red, yellow, green, blue, black. However, due to the production process and other problems, production workers stare at the board for a long time with the naked eye in the case of strong light, which is easy to cause eye fatigue, relatively speaking, green has the least damage to the eyes.

4, the production of green PCB board is very environmentally friendly compared with other colors, when used in a high temperature environment, generally will not release toxic gases.

The reserved process edge is to assist the increased part of the patch plug-in welding on both sides or four sides of the PCB board, mainly to assist production, which does not belong to the part of the PCB board, and can be removed after the PCBA manufacturing production is completed.

PCB design reserved process edge will consume more board, increase the cost of PCB board, so in the design of PCB process edge, need to balance economy and manufacturability. For some special circuit boards, the PCB board that was originally left with 2 process edges or 4 process edges can be greatly simplified by the way of PCB assembling. When designing the assembly method, it is necessary to fully take into account the track width of the SMT mounter, and communicate with the process engineer of the SMT supplier for the assembly whose width exceeds 350mm.

The flatness of PCB design edge is also an important part of printed circuit board production. When removing the PCB design process edge, it is necessary to ensure that the process edge is smooth, especially for the circuit board with high assembly precision, any uneven rough edge will lead to the offset of the installation hole, which will bring great trouble to the subsequent PCBA assembly.

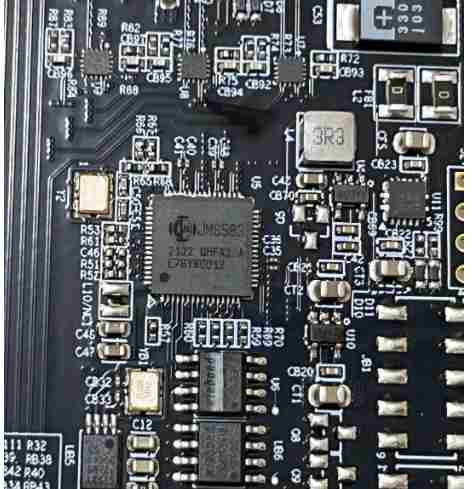

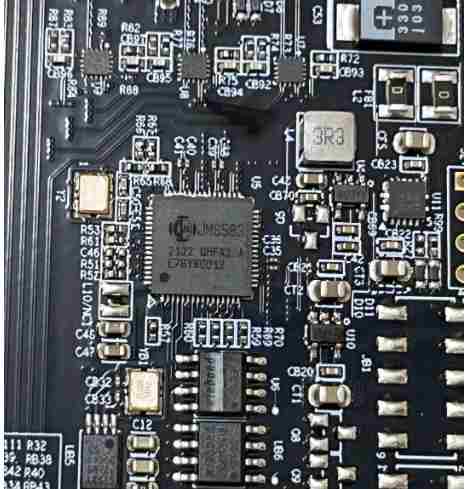

kinhford Electronics Co., Ltd. is committed to providing the best and fastest service for the continuous innovation of electronic technology, and becoming a first-class hardware outsourcing service provider in China. Founded in 1998, the company is headquartered in Shenzhen, and has established production and operation bases in Shenzhen, Huizhou, Guangdong and Yiyang, Hunan, and has a branch in Hong Kong. To provide global customers with professional PCB design, PCB board, SMT processing, PCBA OEM production (OEM supporting processing), PCB secondary development (can provide chip model identification and chip decryption), radio frequency identification technology (RFID) application, smart card management and development and other quality services.

Adhering to the high quality products, fast delivery, perfect service, good reputation, flexible marketing as the basis for market competition, business has expanded to Europe, America, Asia and Australia and other countries and regions. The goal of the future is to establish the world's largest manufacturing platform in the field of sample and small and medium-sized batches, create a senior technical team in the industry, improve the technical comprehensive solution capability in the field of electronic hardware design, combined with the supporting multi-variety rapid processing service capability, to provide customers with personalized one-stop service.

Actively promote the "PCB design - manufacturing - PCBA processing (SMT mount)" one-stop service model, with the goal of "creating the best overall value for the project", to eliminate the inconvenience of multi-party communication, follow-up and coordination of customers in product design, supporting processing and production procurement process management. Through seamless connection of business modules within the company, effectively shorten customer research and development, pilot test and production cycle, reduce the overall cost, and improve the success rate of customer research and development projects through professional technical services. In the field of PCB design, in the face of the challenges of hardware research and development of high-speed signals and RF microwave products, the company's technological innovation has always kept pace with the international market, providing design for customers in RF communications, PC industrial control, network servers, security, digital and other industries; At the same time, the company's SMT processing business is positioned in the rapid delivery mode of multiple varieties, providing the whole process services from component purchase, PCB board making, PCBA processing and welding, online testing, and machine testing, effectively supporting customers to shorten the overall project cycle.