Welding is a very important process in PCBA proofing. So, what are the conditions for PCBA proofing and welding? Next, PCBA processing manufacturer electronics is introduced to you.

PCBA proofing welding to meet the conditions

1. Make the weldment have good weldability

The so-called weldability refers to the ability of the alloy to form a good bond between the metal material to be welded and the solder at the appropriate temperature. Not all metals have good weldability. In order to improve the weldability, measures such as tinning and silver plating can be taken to prevent the surface oxidation of the material.

2. Keep the weldment surface clean

In order to achieve a good combination of solder and weldment, the welding surface must be kept clean. Even weldables with good weldability may produce harmful oxide film and oil stains on the surface of weldparts due to storage or contamination. The dirty film must be removed before welding, otherwise the welding quality cannot be guaranteed.

3. Use the right flux

The function of the flux is to remove the oxide film on the surface of the weldment. Different welding processes should use different fluxes. When welding precision electronic products such as printed circuit boards, rosin based flux is usually used to ensure reliable and stable welding.

4. The welding parts should be heated to the appropriate temperature

The welding temperature is too low, which is not conducive to the penetration of solder atoms, and can not form alloys, so it is easy to form welding failures; If the welding temperature is too high, the solder will be in a non-eutectic state, accelerating the decomposition and volatilization of the flux, reducing the quality of the solder, and in serious cases, causing the pad on the printed circuit board to fall off.

5. Appropriate welding time

Welding time refers to the time required for physical and chemical changes to occur throughout the welding process. When determining the welding temperature, the appropriate welding time should be determined according to the shape, nature and characteristics of the weldment. Welding time is too long, the parts or welding parts are easy to damage; If it is too short, it cannot meet the welding requirements.

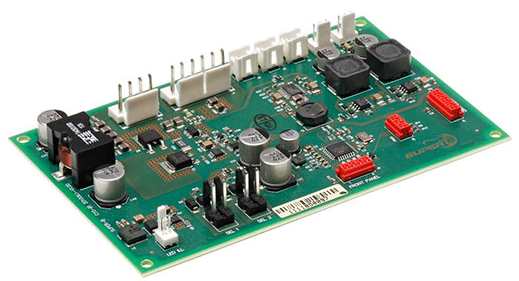

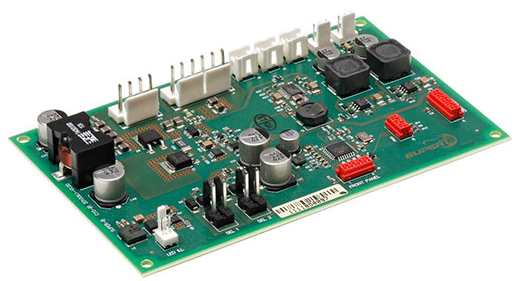

Electronics Co., Ltd. specializes in providing integrated PCBA electronic manufacturing services, including upstream electronic component procurement to PCB production and processing, SMT patches, DIP plug-ins, PCBA testing, finished product assembly and other one-stop services.

The company gives full play to its competitive advantages in scale procurement and quality control, and has signed long-term cooperation agreements with many electronic component manufacturers at home and abroad and around the world to ensure the quality and stable supply of raw materials, and transfer the benefits to customers.

Long-term maintenance of IC, resistors, capacitors, inductors, audiodes and other components procurement advantages, can greatly save customers' inventory costs, improve production turnover efficiency, save time. Currently for the United States, Britain, Japan, Russia, France, Canada, Australia, Romania, Switzerland and other countries and regions to provide PCBA processing services.