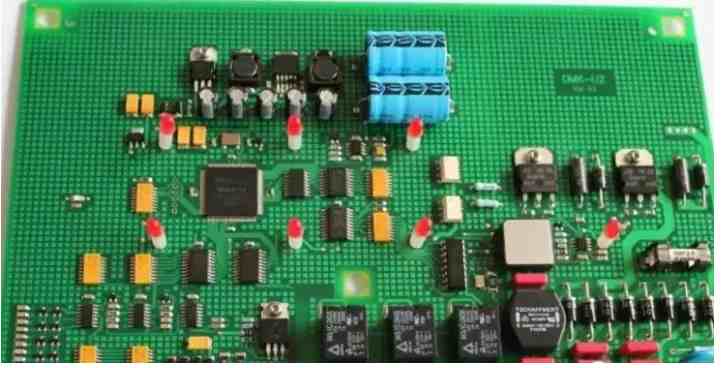

Printed circuit board, also known as printed circuit board, printed circuit board, often use the English abbreviation PCB, is an important electronic component, is the support body of electronic components, is the provider of electronic component circuit connection. Because it is produced by electronic printing technology, it is called a printed circuit board.

In order to understand where the high cost of PCBA small batch proofing is, we need to decompose the entire process of packaging materials, PCBA is the meaning of PCB assembly, then it must include the circuit board, component welding, smt surface mount and DIP plug-in after welding these two parts, the current market price of light plate between 350-550, The prices of components are basically open and transparent in major malls, and can be compared for reference.

Since the main PCB circuit boards and components have no possibility of price increases, the cost is reflected in the assembly process. The main costs of the assembly process are as follows:

1, smt patch processing proofing fee

Patch processing according to the number of points and packaging, the price will have a certain difference. Large quantity and good price is the consensus of the industry, the larger the component package size, the easier it is to mount, the corresponding poor quality will be reduced, so the price also has greater room for communication.

2, DIP plug-in after welding hours

Because the plug-in material link involves shaped parts and material molding, this link requires a lot of manual participation, because there is no production capacity reference of machinery and equipment, this link is the most difficult to control the cost of the link. At the same time, the current labor cost is high, and the cost of this link is generally high.

3, Assembly test fee

Test fixtures, test equipment, test hours, test fixtures are currently ranging from tens to hundreds of dollars according to the difficulty of the test, and the test of communication equipment also needs to be assisted by optical fiber, ICT and other test equipment, the corresponding manual and equipment losses need to be taken into account, but not very high, some companies and even testing are free.

4, auxiliary material costs

The quality of solder paste, tin bar, flux, UV glue, furnace fixture, solder paste and solder bar is the most important auxiliary material in the whole processing link, generally domestic solder paste price in 180~260/ bottle, imported solder paste may be in 320~480/ bottle, then the same welding area, the price of imported solder paste will be much higher. But the quality of the welding is very different.

1. Strength guarantee

▪SMT workshop: With imported SMT machines, optical inspection equipment, can produce 4 million points per day. Each process is equipped with QC personnel, who can keep an eye on product quality.

▪DIP production line: there are two wave soldering, of which there are more than 10 old employees who have worked for more than three years. The workers have high proficiency and can weld all kinds of plug-in materials.

2. Quality assurance, cost-effective

▪ High-end equipment can be attached to precision shaped parts, BGA, QFN, 0201 materials. Also can be template patch, loose material hand. ▪ Sample and size batch can be produced, proofing from 800 yuan, batch 0.008 yuan/point, no start-up fee.

3. Rich experience in SMT and welding of electronic products, stable delivery

▪ Accumulated service for thousands of electronic enterprises, involving many types of automotive equipment and industrial control motherboard SMT processing services, products are often exported to Europe and the United States, quality can be affirmed by new and old customers.

▪ Punctual delivery, normal 3-5 days after complete materials, small batches can also be expedited on the same day.

4. Strong maintenance ability, perfect after-sales service

▪ Experienced maintenance engineers can repair all kinds of patch welding caused by bad products, to ensure the connectivity of each circuit board. 24-hour customer service staff is ready to respond, the fastest to solve your order problems.

One-stop PCBA manufacturing platform, R & D template/small batch, SMT patch,PCB proofing, DIP welding processing,PCB board, electronic components full set of purchasing, some purchasing one-stop PCBA manufacturing services.