SMT proofing small batch processing Many people think that the price is not very cheap, I believe that many customers will have such a feeling, obviously I only do ten twenty board SMT processing, why charge more than 1000 processing fees, this price is a little black.

Many customers who have just come into contact with the SMT patch processing industry should have such an experience, and they were originally holding the mentality of three or five hundred to find a processing plant quotation. As soon as the offer came in, it was several times over budget. When they see this price, they will go directly to find an SMT factory quotation, the result is often similar, manufacturers - for everyone to introduce.

Small batch patch proofing costs mainly include start-up fees, engineering fees, steel mesh fees, processing fees calculated according to conventional points, or directly summarized with the minimum consumption. The minimum consumption is actually the capital protection cost of the electronics processing plant. If this cost is insufficient, it is likely to make no money or even lose money. No one runs a losing business.

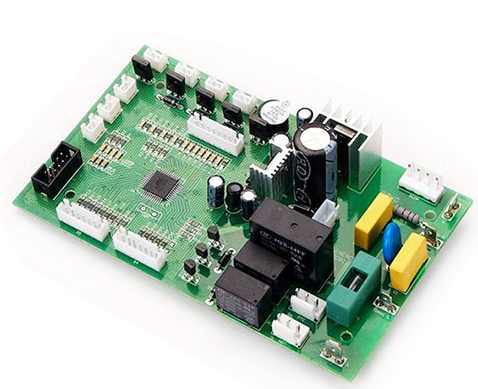

The normal batch of SMT patch proofing processing is generally calculated directly by the cost of the points and then the steel mesh fee, the point calculation standard is generally 0.002-0.03 yuan/point is normal, if there are special requirements, it may be more expensive. The expensive part of small batch proofing of SMT patches is that there are not so many necessary costs to be shared in the processing process. In the actual processing, there is not much difference between 1 board and 100 boards, which are all finished in a while, but the processing process is the same, such as component testing, sample storage system, solder paste temperature mixing, PCB baking, patch programming, SPI testing, AOI testing, first piece testing, aging test, assembly, packaging and shipment of these processing processes are necessary. The labor cost spent above is actually the same, but it is said that there is so much volume to apportion the cost, and small batches can not be apportioned, which is the reason for charging start-up fees or engineering fees.

The low price proofing orders are equipped with a special proofing production line or a small workshop manual patch.

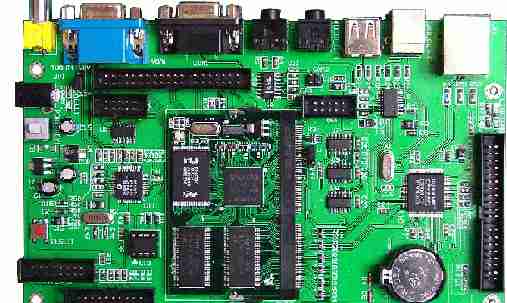

kinhford Electronics Co., Ltd. specializes in providing integrated PCBA electronic manufacturing services, including upstream electronic component procurement to PCB production and processing, SMT patches, DIP plug-ins, PCBA testing, finished product assembly and other one-stop services.

The company gives full play to its competitive advantages in scale procurement and quality control, and has signed long-term cooperation agreements with many electronic component manufacturers at home and abroad and around the world to ensure the quality and stable supply of raw materials, and transfer the benefits to customers.

Long-term maintenance of IC, resistors, capacitors, inductors, audiodes and other components procurement advantages, can greatly save customers' inventory costs, improve production turnover efficiency, save time. Currently for the United States, Britain, Japan, Russia, France, Canada, Australia, Romania, Switzerland and other countries and regions to provide PCBA processing services.