Many friends who just contact the electronics industry, will not understand what PCB, SMT, PCBA, do not know what is the difference between them, what is the correlation. Shenzhen kingford is a professional PCBA manufacturer with its own PCB board factory and SMT processing plant. Next, we will introduce the differences and connections between PCB, SMT and PCBA.

What is PCB, SMT, PCBA?

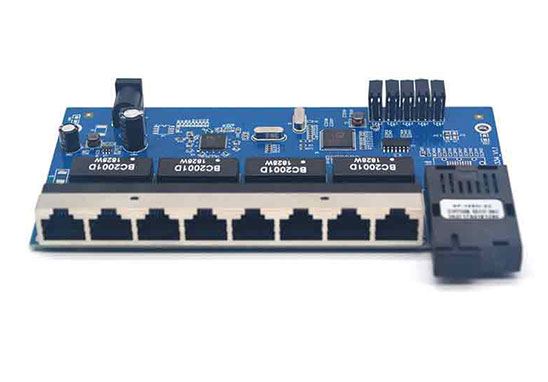

1, PCB Chinese name circuit board, circuit board, printed circuit board and other names, PCB is used to support electronic components, and provide lines, so that electronic components can form a complete circuit.

2. SMT, also known as surface mounting technology, is a popular technology in which electronic components are pasted on PCB empty board through successive processes.

3. PCBA refers to the one-stop processing process of SMT patch, DIP plug-in, test and finished product assembly after purchasing raw materials.

The difference between PCB, SMT and PCBA

1, PCB, also known as circuit board, is the necessary raw materials for SMT processing, only a semi-finished product.

2. SMT is a kind of circuit board assembly technology. It is the most popular technology at present to buy PCB substrate and mount components on PCB through technology.

3. PCBA is a kind of perfect processing service based on SMT, which adds procurement of components, and later testing and assembly of finished products. It is a service mode to provide one-stop service for customers and the direction of future development.

When the processing of an electronic product is completed, their sequence should be PCB→SMT→PCBA. The production of PCB is very complicated, while SMT is relatively simple. PCBA pays attention to one-stop service.

Shenzhen kingford PCB board making ability

Energy production from 2 layers to 14 layers, 14-22 layers can be proofing production.

Minimum line width/spacing: 3mil/3milBGA Spacing :0.20MM

Minimum aperture: 0.1mm Size :610mmX1200mm

Ink: Tamura, Taiyo, Fudoken;

FR4: Shengyi, Kingboard, Harbour, Hongren, Guoji, Hezheng, Nanya,

(Shengyi S1130/S1141/S1170),Tg130℃/ Tg170℃ T g180℃ and other high TG plates)

High frequency plate: Rogers, Taconic, ARLLON;

Surface process: tin spray, lead-free tin spray, gold plating, full plate gold plating, plug gold plating, full plate thick gold, chemical tin (silver), anti-oxidation (OSP) blue glue, carbon oil

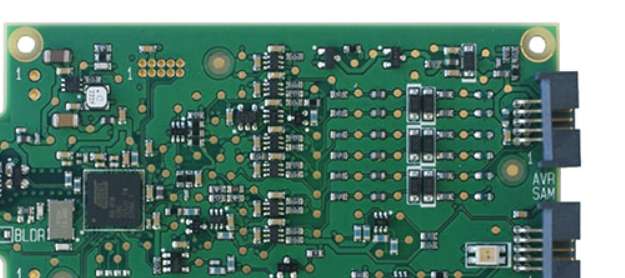

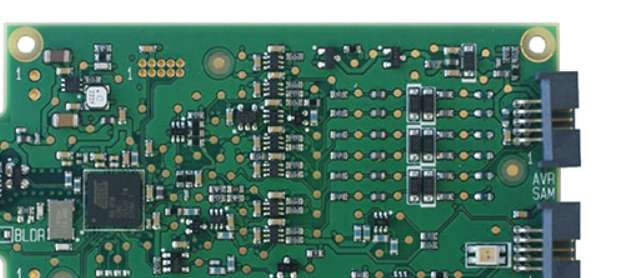

Shenzhen kingford SMT patch processing capacity

1. Maximum board card: 310mm*410mm(SMT);

2. Maximum plate thickness: 3mm;

3. Minimum plate thickness: 0.5mm;

4. Minimum Chip parts: 0201 package or parts above 0.6mm*0.3mm;

5. Maximum weight of mounted parts: 150g;

6. Maximum parts height: 25mm;

7. Maximum parts size: 150mm*150mm;

8. Minimum spacing of pin parts: 0.3mm;

9. Minimum ball parts (BGA) spacing: 0.3mm;

10. Minimum ball parts (BGA) ball diameter: 0.3mm;

11. Maximum parts mounting accuracy (100QFP) : 25um@IPC;

12. Patch capacity: 3-4 million points/day.

Why choose Shenzhen Honglijie to do PCBA processing?

1. Strength assurance

▪ SMT workshop: We have imported SMT machines and a variety of optical testing equipment, capable of producing 4 million pieces per day. Every process is equipped with QC personnel who can keep a close eye on product quality.

▪ DIP production line: There are two wave welding machines. Among them, there are more than ten old employees who have worked for more than three years. Skilled workers can weld all kinds of insert materials.

2. Quality assurance, high cost-effective

▪ High-end equipment can mount precision heterosexual parts, BGA, QFN, 0201 materials. Proofing can be machine paste, also can be hand pendulum.

▪ Samples and large and small batches can be produced. Proofing starting price 800 yuan, batch starting price 0.008 yuan/point, no start-up fee.

3. Rich experience in SMT and welding of electronic products, stable delivery time

▪ Has served thousands of home appliance subsidiaries, involving various kinds of automotive equipment and industrial control motherboard SMT SMT processing services. Products are often exported to Europe and the United States, the quality of new and old customers affirmed.

▪ On time delivery, usually within 3-5 days after the board is assembled, small batch expedited can also be shipped on the same day.

4. Strong maintenance ability and perfect after-sales service

▪ Experienced maintenance engineers are able to repair defective products caused by various welding problems and ensure the connectivity rate of each circuit board.

▪ 24-hour customer service staff will be ready to respond and resolve your order as soon as possible.