Copper if not flat will crepe, PCB pressure board using thinner copper crepe crepe chance is higher, thicker copper is relatively will produce compression Nuo flat effect to reduce crepe opportunity. If the operation has confirmed that the copper skin is smooth, it is necessary to see whether the substrate blank area of the problem. If the film produces a lot of flow during the melting process, it will produce the possibility of sliding copper sheet with poor support. Therefore, most circuit board manufacturers will pay attention to the inner substrate circuit configuration problems, and try to avoid making the empty area too obvious. Most copper crepe will occur in areas where the line density is different, especially where one side is designed to be large copper but the other side has a large empty area.

In addition, the film (PP) combination and hot pressing parameters are also very important. If the film superposition moves or produces flow glue improperly, the copper floating in the melt resin table will inevitably produce crepe. In order to prevent this kind of problem, the carrier plate is the focus of the operation. Most of the carrier plate designs currently used in the industry have adopted a highly elastic skid control design that completely prevents the plate from slipping during the plate pressing process, thus preventing the resulting crepe from occurring.

As for the choice of film, do not use the high glue content type as much as possible, and the press heating rate should be low, as long as it can be packed completely. If the PCB circuit board produced has been wrinkled, in the case of loose product specifications, you can consider removing the surface copper and remaking the pressing. Although the plate thickness will be slightly higher, but if the customer's specifications can be accepted, it can still be remedied. The above is for your reference.

PCB manufacturers, teach you how to maintain the circuit board

Many people will have such a problem, PCB circuit board should be how to maintain? How does ability make PCB board life longer? Now by the Ke you circuit to analyze the maintenance of PCB circuit board for you.

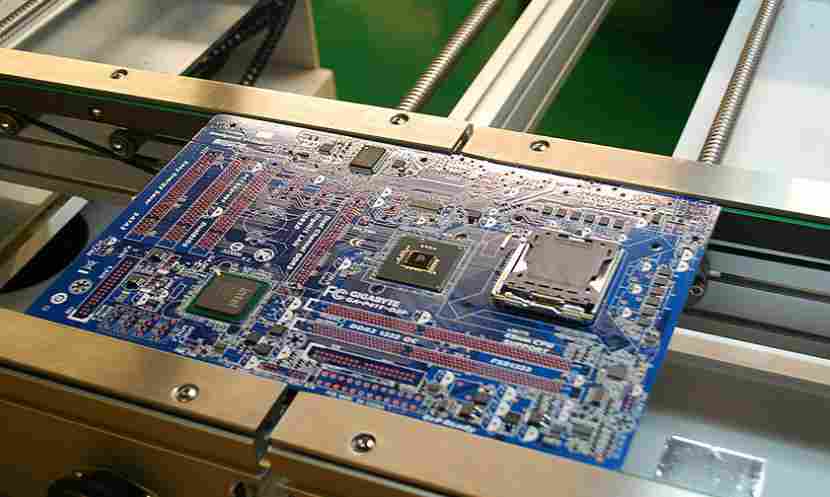

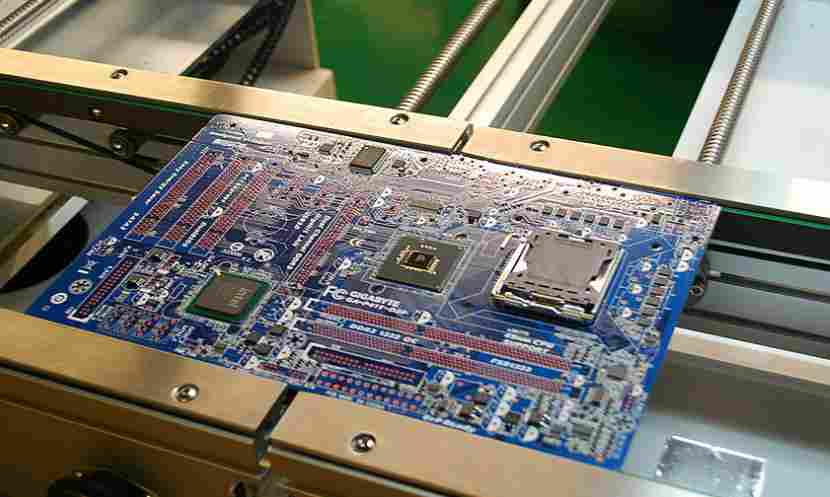

PCB circuit board uses the method of printing etch inhibitor to make circuit lines and drawings. PCB circuit board can be divided into single panel, double panel and multilayer board according to the number of circuit layers. Common multilayer board is generally 4 or 6 layers, complex multilayer board can reach more than a dozen layers. The PCB circuit board has both high-speed logic circuit and linear circuit, they should be separated as far as possible, and the ground wire of the two do not mix, respectively connected with the ground wire of the power supply. The ground area of the linear circuit should be increased as much as possible. How should PCB board be maintained?

One, half year maintenance:

Observe the trace of electronic components in the circuit after high temperature, electrolytic capacitor does not bulge leakage phenomenon, if there should be replaced.

Clean the dust on the PCB circuit board every quarter. The PCB circuit board can be cleaned with special cleaning liquid. After cleaning the dust on the PCB circuit board, dry the PCB circuit board with a hair dryer.

Ii. Annual maintenance:

Clean the dust on the PCB circuit board.

The capacity of electrolytic capacitor in PCB circuit board is randomly checked. If the capacity of electrolytic capacitor is found to be less than 20% of the nominal capacity, it should be replaced. Generally, the life of electrolytic capacitor should be replaced for about ten years to ensure the working performance of PCB circuit board.

For high-power devices coated with heat dissipation grease, check whether the heat dissipation grease is solid. For dry solid devices, remove the heat dissipation grease and apply new heat dissipation grease to prevent the high-power devices in the PCB circuit board from burning out due to poor heat dissipation.

How to Improve the oxidation analysis Circuit of sunken gold circuit Board?

It is conceivable that Keyou Circuit has become a discussion group for poor oxidation of sunken gold board, which is common in the circuit board industry. The participants include quality, process, customer service and suppliers, etc., to discuss and improve this problem together. After about a week of field observation and experiment, this problem has been comprehensively improved. The following analysis is made on the oxidation of the sunken gold plate, and the following improvement measures are implemented after discussion:

1. Poor oxidation of sunken gold plate

Two, sinking gold plate oxidation instructions:

The oxidation of sunken gold plate is the contamination of the gold surface by impurities. The impurities attached to the gold surface change color after oxidation, which leads to the oxidation of the gold surface. In fact, the statement of gold surface oxidation is not accurate, gold is an inert metal, under normal conditions will not occur oxidation, and impurities attached to the gold surface such as copper ions, nickel ions, microorganisms in the normal environment easy oxidation metamorphism to form gold surface oxide. Three, through observation found that the oxidation of gold-sunk circuit board mainly has the following characteristics:

1, improper operation causes pollutants to adhere to the gold surface, such as: with unclean gloves, finger cover contact with gold surface, gold plate and unclean table, plate contact pollution; This kind of oxidation area is large, may appear at the same time in the adjacent multiple pads, the appearance of light color is easier to clean.

2, poor water quality leads to impurities in water adsorption on the gold surface, such as: gold after washing, finished product washing machine washing; This kind of oxidation area is small, usually appears in the corner of the individual pad, is more obvious water stains; Water droplets will be retained on the welding pad after washing the gold plate. If the water contains more impurities, the water droplets will quickly evaporate and shrink to the corner of the plate at a higher temperature, and the impurities will be solidified in the corner of the pad after water evaporation; The main pollutants in washing after sinking gold and washing by finished plate washing machine are micro-bacteria. Especially, the tank using DI water is more suitable for fungus reproduction. The best test method is to touch the dead corner of the tank wall with bare hands to see if there is a smooth feeling.

3, half plug hole, through the hole near a small range of oxidation; This kind of oxidation is due to yao water in the perforated or half-plugged holes not being cleaned or residual water vapor in the holes. During the storage stage of finished products, yao water slowly diffused along the pore wall to form dark brown oxides on the gold surface.

4, the analysis of customer returns board, found that the gold surface density is poor, nickel surface has slight corrosion phenomenon, and the oxidation contains abnormal element Cu, the copper element is very likely due to the poor density of gold nickel, copper ion migration, such oxidation removal, still grow out, there is a risk of oxidation again.