But in the general design can not use the case of BGA packaging as far as possible not to use, the reason is that BGA packaging is difficult to weld, can not check the packaging inside the solder situation.

Circuit board short circuit: when the circuit board welding after the aging process will be found in some circuit board short circuit, out of the circuit board design and electronic original device problems, can be found from the following aspects when the circuit board soldering tin eating time is too short, resulting in poor welding. The activity of the flux itself is not strong, which weakens the wettability of the solder and its expansibility. The direction of the circuit board into the tin and the direction of the tin wave is opposite, the solder liquid surface oxide too much affect the welding.

Solder after the tin point dull grey: solder after the tin point is found to be dull, from two aspects, one is the degree of solder is too low. Circuit board welding. Solder solder to contain more than 50% tin solder spot will have luster. On the other hand, the residue of flux stays on the surface of the tin spot without cleaning and its acid corroded solder spots will also cause the tin spot gray luster.

After soldering, the surface of the tin point is rough: the roughness of the surface of the tin point should first be from the quality of the solder, the solder itself contains a variety of small amounts of metal elements, when the content of these metal elements exceeds its limit will affect the surface of the tin point. When soldering, the surface of the tin liquid is required to be free of impurities. When the surface of the tin liquid is oxidized too much, it should be cleaned up in time, otherwise it will affect the surface of the tin point.

Yellow solder joint color: Yellow solder joint color is a common problem, many people do not know the reason. When the color of the solder appears, there is generally a considerable relationship with the temperature. When the solder temperature is too high, the surface of the liquid tin appears yellow. At this time, it is necessary to adjust the temperature of the tin furnace to the appropriate operating temperature.

How to save cost and maintain quality of the circuit board

In recent years, with the increase of labor cost and raw material price again and again, many customers began to require product price reduction to save costs. Circuit board manufacturers just located in the middle of the whole food chain, we do circuit board, the next to face plate suppliers and other auxiliary material suppliers of the price, to face the customer requirements of the price reduction, but also in the face of the growth of labor costs, we all racking their brains to think of how to save costs and to ensure quality.

Batch delivery of the circuit board is based on the basis of proofing, only after the sample qualified, the product can be mass-produced. If the size of the product is large, the one-time production can be satisfied. However, if the size of the product is small, the one-time material will produce inventory after delivery. If the customer samples are directly mass produced through OK, less material can be added during mass production. Can empty the inventory, but if the customer sample test is unqualified, need to revise, then the inventory can only be scrapped.

In order to solve this problem, we can choose the same material, the same plate thickness and the same process of the product, and make it together, which has achieved the effect of reducing inventory and saving cost.

When the appearance of customers' products is irregular, we can not according to the ordinary style of the plate, according to its different shapes, design inverted, concentric circles or two large boards with small boards in the middle of the way to improve the utilization rate of the board, save costs.

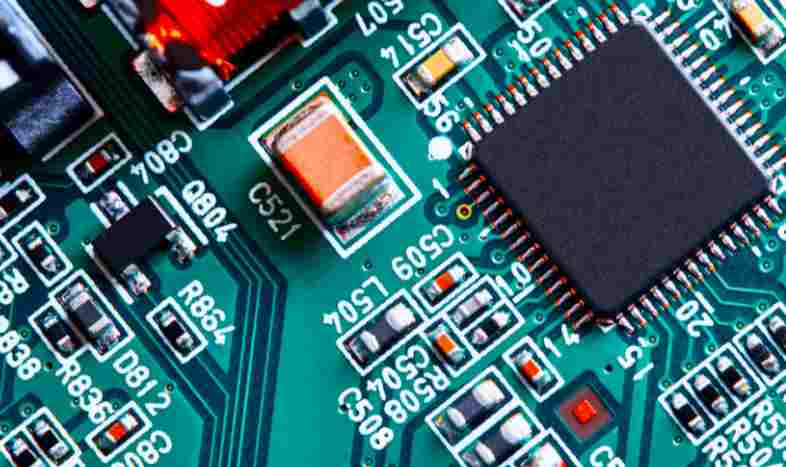

Multilayer PCB board, multilayer PCB board,PCB board

Shenzhen Keyou Circuit Technology Co., Ltd. was founded in 2003, is a professional rapid production of high precision double-sided, multi-layer circuit board (1-26 layers), LED aluminum substrate, Thermoelectric separation single-side/double-sided copper base board, industrial circuit board, power pcb board, medical circuit board, security PCB board, communication PCB board, automotive circuit board, instrument circuit board, military circuit board,FPC soft and hard combined board,PCB manufacturers, circuit board manufacturers, circuit board manufacturers, thermoelectric separation copper base board, multi-layer circuit board factory, quality assurance, delivery on time, to Sales as one of the high-tech enterprises.

Factory introduces advanced circuit board equipment, employ experienced professional talents for management. Is a strong scale, sophisticated equipment, strict management, excellent quality circuit board production enterprises. Since its establishment in 2003, the company has developed rapidly, with more than 5000 square meters of plant and more than 280 employees. Products have obtained ISO9001, SGS certification, also obtained the European Union ROHS certification and the United States UL certification. The introduction of a complete set of advanced production equipment, training a professional team engaged in the processing of printed circuit board, perfect from market development, engineering design, to processing and production of one-stop services. The company to produce quality products, return to the society of management purposes. The wide recruitment of talents as the enterprise based on this, product quality as the life of the enterprise, to provide customers with the best quality products, the most satisfactory service.

The company now has a full set of printed board production and testing equipment introduced from the United States, Japan, Taiwan and other countries and regions, with a group of high-quality management, scientific and technical personnel and trained staff.

Our products include: High precision double-sided/multi-layer board (2-26 layers), high TG thick copper foil board, hot air leveling, full plate gold plated, coated iron dragon and other printed boards, in addition to the production of difficult backboard, PCMCIA and half-hole plate, special material board such as ceramic board, PTFE high-frequency board, metal substrate, mixed media board, HDI board, and a variety of customized special circuit boards. The company's products are widely used in LCD module, communication equipment, instruments, industrial power, digital, security, medical electronics, industrial control equipment, LED modules/modules, power energy, transportation, science and education research and development, automotive, aerospace and other high-tech fields.