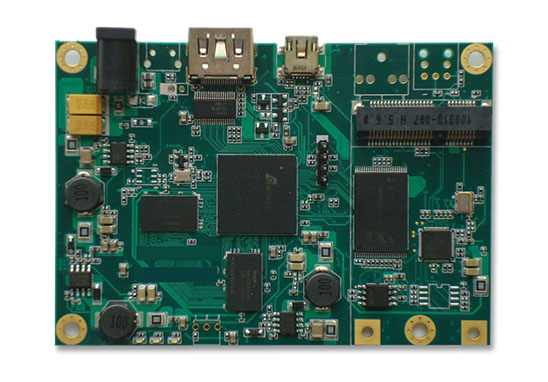

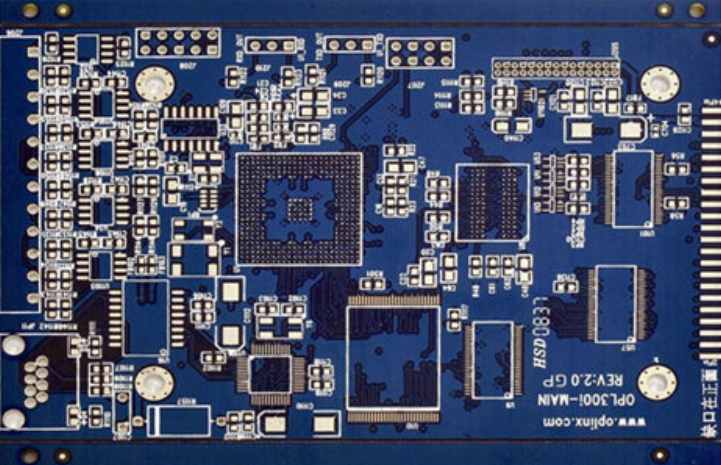

Printed circuit board (PCB) is not only bearing a variety of electronic components, components and integrated circuits of the most important fixed, linked, assembly of mechanical support, but also can make electronic products with high reliability, good consistency, high mechanical strength, light weight, small size, easy to standardize and other advantages and characteristics of the basic parts. Although PCB can be called the high-tech products in the electronic industry, but now the development of PCB is not only challenged by its own cost-effectiveness problems, more is the challenge from the peripheral energy conservation and environmental protection, especially the requirements of the electronic product production enterprises and the requirements of the society. Therefore, PCB must take the road of green development, must put energy saving and pollution reduction in an important position in the development of the industry.

With the rapid development of the industry, the competition in the PCB industry is becoming more and more fierce. Carrying out energy conservation and consumption reduction is not only implementing the national policy of energy conservation and emission reduction, but also an important means for enterprises to reduce production costs and improve their competitiveness. The energy saving of PCB enterprises only depends on technological progress, especially on the innovation of PCB production process. Although the overall is difficult, but can start from the local, step by step, step by step to change the lengthy PCB process, I believe that "long process" to "short process" will achieve energy saving. At present, we can start from the following aspects.

First, we should make unremitting efforts to continue to promote the digital inkjet printing technology to replace screen printing, and promote the use of 3D printing technology to replace the etching of PCB electronic circuit, which will be one of the ways for PCB enterprises to achieve energy saving.

Second, vigorously promote the compressed air energy saving program. Compressed air is the most widely used in PCB enterprises, and the energy consumption of compressed air accounts for 20%-35% of the total power consumption in most manufacturing plants. The energy saving of force attack compressed air can make the energy saving work of PCB industry receive twice the result with half the effort.

Third, increase efforts to take effective measures in the PCB board plating link, adopt energy-saving electroplating power supply, improve the plating efficiency, which can also receive surprising energy-saving effect. For example, in the aspect of pore metallization, the organic conductive film direct plating technology in recent years has been recognized and used by more and more enterprises. The polymer conductive film direct plating technology with many advantages has also been accepted by the market and widely used. And hole metallization process formaldehyde-free gas emissions, not only make the working environment has been greatly improved, but also no complexing wastewater, simple treatment method, greatly save water and electricity, greatly reduce operating costs, horizontal transmission is easy to automation.

Fourth, promote high-efficiency energy-saving motors in PCB enterprises, and carry out technical transformation of PCB production equipment. The industry association can lead to introduce energy-saving service companies and institutions, and innovate energy-saving mode, which is expected to achieve about 20% energy-saving effect.

At present, PCB industry clean production has started, but still need to push forward. First, the most important thing is to achieve stable wastewater discharge standards at all times, 365 days a year, 24 hours a day, PH, Cu, Ni, COD, ammonia nitrogen and other indicators to meet the standards. To make all PCB enterprises with law-abiding consciousness, integrity consciousness, environmental awareness. Second, waste water recycling. To establish the standard of waste water reuse, strict requirements of the proportion of treated waste water back to the production line for use. Third, vigorously control PCB production of heavy metal pollution, copper and a small amount of nickel in the discharge wastewater, according to environmental protection discharge standards for treatment, to minimize the content of copper and nickel in the discharge wastewater, promote the wastewater production and processing of these two metals into metal mud, as raw materials for smelters, to achieve waste recycling. Fourth, strengthen cooperation with potion manufacturers to develop environmental protection potion; Because the environmental protection chemical potion of waste gas, waste water, waste emissions less, easy to deal with, friendly working environment, the health of the workers also get more protection. Fifth, actively cooperate with electrical and electronic machine enterprises to limit the use of harmful substances in products (RoHS).

In general, the development of PCB industry depends on technology and energy conservation and environmental protection of the two-wheel drive, but the current energy conservation and environmental protection of PCB industry is more important, even directly affect the survival of some enterprises. The realization of green manufacturing in PCB industry can not be achieved overnight, it must be regarded as the development direction of the industry, and strive to promote it; This requires the promotion of laws and regulations, the guidance of policies, the formulation of standards and norms, and the creation of an atmosphere of corporate social responsibility. At the same time, it also needs industry organizations to play a role in uniting and leading enterprises to cooperate with each other and develop cooperatively; Finally, we should abide by market rules and give play to the role of market mechanism in allocating resources.