What types of solder pastes are used in SMT chip processing

Composition of SMT solder paste

As the name implies, solder paste is an object similar to solder paste, and its shape is very similar to the toothpaste we use every day. The main component of solder paste is a mixture of tin powder and flux.

If the proportion of solder paste is calculated by weight, the proportion of solder powder and flux is about 90%: 10%; Because tin powder is heavy; If the proportion is calculated by volume, the proportion of tin powder and flux is about 50%: 50%;

Role of Solder Paste in SMT Patch

Solder paste is an indispensable material for electronic technology progress.

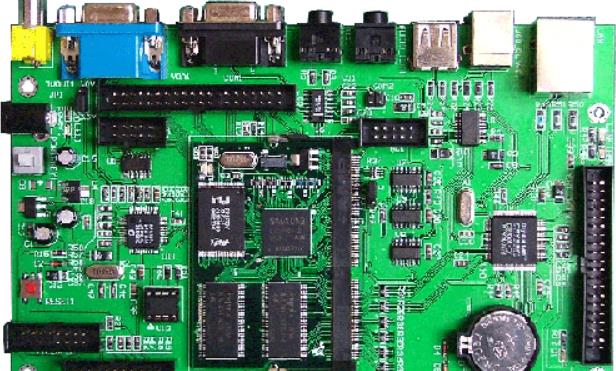

Circuit board

It is used for soldering electronic components on circuit boards Because the invention of solder paste has promoted the miniaturization of electronic assembly technology, PCBA circuit boards continue to become smaller, and the number of integrated circuit components continues to decrease, making mobile phones we use smaller and smaller From the old Big Brother to the current smart phone, the appearance is becoming more and more beautiful, the size is smaller, and more and more functions are available

Extended reading: How does SMT chip processing solder paste printer work on PCB?

Solder paste is applied to the PCB. Before welding, the solder paste adheres to the electronic components placed on the surface of the circuit board, so that the components will not deviate under slight vibration. The biggest function is to weld electronic components. The circuit board realizes the purpose of electronic communication.

Solder Paste Type

According to environmental requirements, it can be divided into lead tin paste and lead-free solder paste (environmental solder paste):

This environment-friendly solder paste only contains a small amount of lead, which is harmful to human health. Lead content in electronic products exported to Europe and the United States is strictly required. This, lead-free process is used in SMT chip processing

In the processing of lead-free SMT chips, it is more difficult to tin with lead, especially in the case of BGAQPN, which will use a high proportion of silver solder paste. The silver medal of 3 points and 0.3 points are common in the market. Among solder pastes, silver containing solder pastes are currently more expensive.

According to the melting point, there are three types: high temperature, medium temperature and low temperature:

The common high temperature is tin silver copper 3050307. Tin, bismuth and silver are available at medium temperature, and tin and bismuth are commonly used at low temperature, which can be selected according to different product characteristics in SMT wafer processing.

According to the fineness of tin powder, it can be divided into 3 # powder, 4 # powder, 5 # powder and solder paste:

Selection: When processing generally large components (1206 0805 LED lamp) on SMT chip, use No. 3 powder solder paste because its price is relatively cheap.

Digital products have dense pin integrated circuits, and No.4 powder solder paste is used for SMT chip processing.

When very precise welding components (such as BGA) and demanding products (such as mobile phones, tablet computers and SMT chip processing) are encountered, No. 5 powder solder paste will be used.

SMT patch for storage and use environment of solder paste

1. After receiving the solder paste, please put it into the freezer immediately and store it in the freezer at 3-7 ° C. Be careful not to freeze the solder paste.

2. Preparation before solder paste printing: Take the solder paste out of the freezer and perform the following 2 steps before putting it into the printing process:

Do not open the package. Keep it at room temperature for at least 4-6 hours to make the solder paste temperature rise naturally to room temperature.

After the temperature of the solder paste reaches room temperature, it must be stirred before being put into printing to ensure that the components in the solder paste are evenly distributed. It is recommended to use special mixing equipment to mix in the same direction for 1-3 minutes.