7 Tips for PCB Assembly Files

After the design process is completed, it must be provided to the appropriate PCB supplier Then it is necessary to provide the PCB manufacturer with a complete PCB file A complete PCB file is essential because it provides PCB manufacturers with complete PCB production information, layout, required materials, etc It also helps to find and solve problems in time, and helps to improve PCB assembly speed Therefore, a complete PCB file is essential Some of the technologies that must be considered when preparing PCB assembly dossiers include:

Clear assembly drawing

Before manufacturing PCB, it is better to have a clear assembly drawing for design. In order to ensure the successful manufacturing of PCB, designers must understand everything the manufacturer needs in the drawings.

·Stacked View

During the recording process, you must specify the different layer sizes and board data that the manufacturer will use to manufacture the circuit board. You can include detailed information about the board information in the drawing notes to ensure that you do a good job during PCB assembly.

·Dimensions

(including PCBs) is as error free as possible Emphasizing your special handling requirements will enable your PCB manufacturer to understand the design

Printed circuit board. Printed circuit board. Background or banner. Jpg "title=" Digital integrated technology. PCB. PCB. Background or banner "/>

Circuit board

Problems in bill of materials

The bill of materials (BOM) is a comprehensive list of all raw materials, components, components and other basic product manufacturing data. If the bill of materials for PCB is incorrect, the manufacturer or assembler may encounter some problems in the design and assembly process. The content statement needs to be accurate and in sufficient detail to enable the printed circuit board assembly to meet the customer's specifications.

·Description Matching

Be sure to provide a detailed description of the desired PCB appearance before handing this work over to the PCB designer or assembler. Your BOM should include basic requirements and other necessary items. If you do not include these requirements, your PCB assembler may ignore these items. Make sure to provide a detailed list of PCB parts, such as voltage, color, size, etc. By providing this information, the manufacturer will use the correct component for your PCB assembly.

·Correct part number

By listing the manufacturer's part number on the bill of materials, you will ensure that the PCB assembler uses the correct information on the BOM. Incorrect part numbers slow down the PCB manufacturing process. Recall that you must record the correct part number to avoid any delay.

·Complete information

The BOM should contain all the information required by the PCB manufacturer or assembler, and there is no room for guessing. Provide a complete list of information to avoid any form of error, which will lead to waste of time, energy, resources and money. Some of these reports include purchase type, packaging type, flexible quota, part number, part quantity, supporting files, placement method, etc. Please make sure to include complete information, as omission may waste time. If you need to change the information on the BOM, make sure your PCB designer updates the BOM after the change takes effect.

Gerber archives

Gerber is a file format that can be used to provide design data to PCB manufacturers or assemblers. Gerber file is an open ASCII vector format file, which contains information about each PCB layer. The assembly program will use this information during PCB assembly. For Gerber files, you must create an important file and this component will be used to create PCBs. For example, it contains a circuit board object;

1. Copper wire

2. Silk

3. Solder mask

4.Pad

5. Silk screen image

PCB manufacturers usually use Gerber archives to convert the details of PCB design into physical components of PCB. By properly recording Gerber files, PCB manufacturers will make circuit boards according to your specific needs.

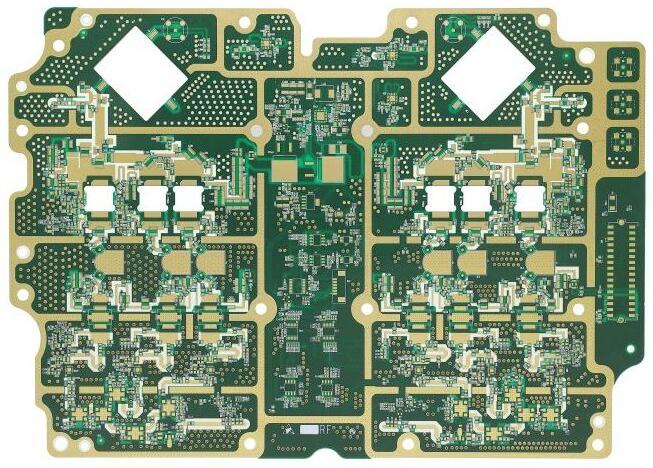

Layout PCB using internal Gerber archives

Supplier List

In the development of electronic equipment schematics and bills of materials, the electronic designer will also improve the approved supplier list (AVL). Your supply base AVL must be checked. It will enable you to understand which suppliers to keep and which to give up. By clearly understanding your AVL, you will understand the companies that meet your PCB needs and determine the amount of your spending in each supply chain. A detailed list of suppliers will help you improve your negotiation skills and determine the ranking of suppliers.

After compiling AVL, learn more about them, such as their brand expertise, payment terms, projects, and other important information you need to know before starting business with them.

Ensure understanding of PCB archive standards

PCB archive standards must be fully understood to ensure the quality of the entire manufacturing process. One way to achieve PCB excellence and accuracy is to follow the rules of the Electronic Interconnection Industry Association IPC. IPC provides electronic equipment assembly rules, training, public policy publicity and market research.

IPC standards can help PCB manufacturers and assemblers produce reliable and high-performance PCB products to meet customer needs. By complying with IPC standards, your PCB manufacturer will provide high-quality PCB products, thereby enhancing your company's reputation.

Files you usually forget

PCB archive standards must be fully understood to ensure the quality of the entire manufacturing process. One way to achieve PCB excellence and accuracy is to follow the rules of the Electronic Interconnection Industry Association IPC. IPC provides electronic equipment assembly rules, training, public policy publicity and market research.

IPC standards can help PCB manufacturers and assemblers produce reliable and high-performance PCB products to meet customer needs. By complying with IPC standards, your PCB manufacturer will provide high-quality PCB products, thereby enhancing your company's reputation.

Characteristics of high-quality archives

Some contents of high-quality PCB archives include:

Dimension hardware diagram

Bill of Materials (BOM)

PCB archives may cause stress and inefficiency. It is an honor for every customer to obtain reliable and high-quality circuit boards. Follow the above instructions and you will get an error free PCB. Make sure your PCB manufacturer or assembler has the right information and skill set to make your PCB design a reality.

We hope to obtain professional knowledge and excellent quality in current or future PCB rapid prototyping 3D PCB printing not only makes PCB but also performs printed circuit board assembly (run Wuzhou PCB, we have experts to provide you with cost-effective services. We provide PCB manufacturing printed circuit board assembly (SMT PCB assembly, SMD PCB assembly) and other high quality services Contact us immediately to make an appointment and learn more about PCB requirements