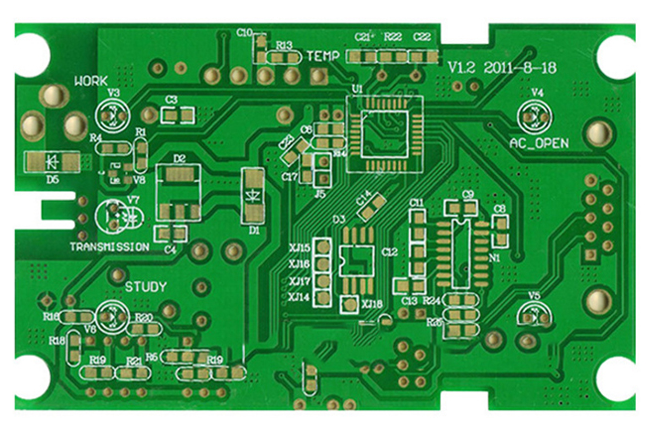

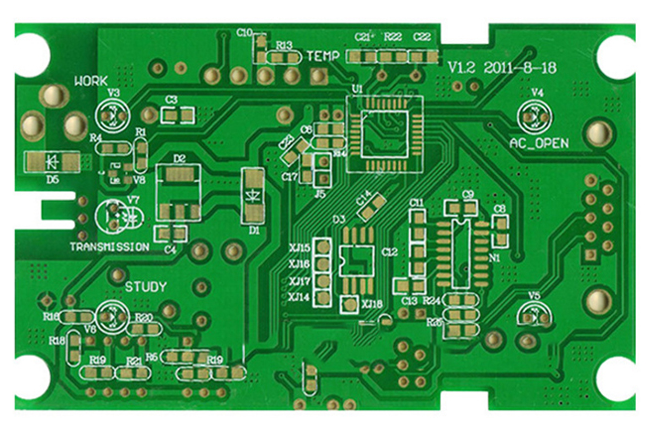

Differences between different materials of electronic engineering PCB boards

The circuit board must be flame resistant, cannot burn at a certain temperature, and can only be softened. The temperature point at this time is called glass transition temperature (Tg point), which is related to the dimensional stability of PCB.

What are high Tg PCB circuit boards and the advantages of using high Tg PCB?

When the temperature of high Tg printed circuit board rises to a certain area, the substrate will change from "glass state" to "rubber state", and the temperature at this time is called the glass transition temperature (Tg) of the board. That is, Tg is the highest temperature for the substrate to maintain rigidity.

What are the specific types of PCB boards?

According to the grade level, it is divided from bottom to top as follows:

94HB - 94VO - 22F - CEM-1 - CEM-3 - FR-4

Details are as follows:

94HB: ordinary cardboard, not fireproof (the lowest grade material, die punching, cannot be used as power board)

94V0: Flame retardant cardboard (die punching)

22F: one-sided semi fiberglass board (die punching)

CEM-1: single-sided fiberglass board (computer drilling is required, die punching is not allowed)

CEM-3: double-sided semi fiberglass board

This material can be used for double-sided boards, which will be 5~10 yuan/m2 cheaper than FR-4)

FR-4: double-sided fiberglass board

The circuit board must be flame resistant, cannot burn at a certain temperature, and can only be softened. The temperature point at this time is called glass transition temperature (Tg point), which is related to the dimensional stability of PCB.

What is a high Tg PCB and the advantages of using a high Tg PCB? When the temperature of a high Tg PCB rises to a certain area, The substrate will change from a "glass state" to a "rubber state", and the temperature at this time is called the glass transition temperature (Tg) of the board. That is, Tg is the highest temperature (℃) at which the substrate can maintain its rigidity. That is to say, ordinary PCB substrate materials not only produce softening, deformation, melting and other phenomena at high temperatures, but also show a sharp decline in mechanical and electrical properties (I don't think you want to see the classification of pcb boards as their own products) 。

Generally, the Tg of the plate is more than 130 degrees, the high Tg is more than 170 degrees, and the medium Tg is more than 150 degrees. Generally, PCB printed boards with Tg ≥ 170 ℃ are called high Tg printed boards. The Tg of the substrate is increased, and the heat resistance, moisture resistance, chemical resistance, stability resistance and other characteristics of the printed board will be improved. The higher the TG value is, the better the temperature resistance of the plate is. Especially in the lead-free process, high Tg is used more frequently.

High Tg refers to high heat resistance. With the rapid development of electronic industry, especially the electronic products represented by computers, which are developing towards high functionality and high multilayer, higher heat resistance of PCB substrate materials is required as an important guarantee. With the emergence and development of high-density installation technology represented by SMT and CMT, PCB is increasingly dependent on the support of high heat resistance of the substrate in terms of small aperture, fine wiring and thinness.

Therefore, the difference between the general FR-4 and the high Tg FR-4 is that in the hot state, especially in the heat after moisture absorption, the mechanical strength, dimensional stability, adhesion, water absorption, thermal decomposition, thermal expansion and other conditions of the materials are different. The high Tg products are obviously better than the ordinary PCB substrate materials. In recent years, the number of customers requiring to produce high Tg printed boards has increased year by year.

With the development and continuous progress of electronic technology, new requirements are constantly put forward for PCB substrate materials, thus promoting the continuous development of copper clad foil standards. At present, the main standards of substrate materials are as follows.

① National standards At present, China's national standards for the classification of pcb boards as substrate materials include GB/T4721-47221992 and GB4723-4725-1992. The standards for copper clad laminates in Taiwan, China, China, are CNS standards, which were formulated based on Japanese JIS standards and issued in 1983.

② Other national standards mainly include: Japanese JIS standards, American ASTM, NEMA, MIL, IPc, ANSI, UL standards, British Bs standards, German DIN, VDE standards, French NFC, UTE standards, Canadian CSA standards, Australian AS standards, former Soviet Union FOCT standards, international IEC standards, etc

● Accepted documents: protel autocad powerpcb or cad gerber or solid board copying, etc

● Plate type: CEM-1, CEM-3 FR4, high TG material;

● Maximum panel size: 600mm * 700mm (24000mil * 27500ml)

● Thickness of processing plate: 0.4mm-4.0mm (15.75mil-157.5mil)

● Maximum processing layers: 16Layers

● Copper foil thickness: 0.5-4.0 (oz)

● Thickness tolerance of finished plate:+/-0.1mm (4mil)

● Forming dimension tolerance: computer milling: 0.15 mm (6 mil) Die plate: 0.10 mm (4 mil)

● Minimum line width/spacing: 0.1mm (4mil) Line width control capacity: <+- 20%

● Minimum borehole diameter of finished product: 0.25mm (10mil)

Minimum punching hole diameter of finished product: 0.9mm (35mil)

Finished aperture tolerance: PTH:+-0.075mm (3mil)

NPTH:+-0.05mm(2mil)

● Copper thickness of finished hole wall: 18-25um (0.71-0.99mil)

● Minimum SMT tip spacing: 0.15 mm (6 mil)

● Surface coating: chemical gold deposition, tin spraying, whole plate nickel plating gold (water/soft gold), silk screen blue glue, etc

● Thickness of solder mask on plate: 10-30 μ m(0.4-1.2mil)

● Peel strength: 1.5N/mm (59N/mil)

● Hardness of solder mask: > 5H

Resistance welding plug hole capacity: 0.3-0.8mm (12mil-30mil)

● Medium constant: ε= 2.1-10.0

● Insulation resistance: 10K Ω - 20M Ω

● Characteristic impedance: 60 ohm ± 10%

● Thermal shock: 288 ℃, 10 sec

● Warpage of finished board: < 0.7%

● Product application: communication equipment, automotive electronics, instrumentation, global positioning system, computer, MP4, power supply, household appliances, etc

According to PCB board reinforcement materials, they are generally divided into the following categories:

1. Phenolic PCB paper substrate

Because this kind of PCB board is composed of pulp and wood pulp, it sometimes becomes cardboard, V0 board, flame retardant board and 94HB. Its main material is wood pulp fiber paper, which is a kind of PCB board compressed and synthesized by phenolic resin.

The paper substrate is characterized by non fireproof, punching processing, low cost, low price and low relative density. We often see XPC, FR-1, FR-2, FE-3, etc. for phenolic paper substrate. The 94V0 belongs to flame retardant paperboard and is fireproof.

2. Composite PCB substrate

This kind of board is also called powder board, which is made of wood pulp fiber paper or cotton pulp fiber paper as reinforcement material, and glass fiber cloth as surface reinforcement material. Both materials are made of flame retardant epoxy resin. There are single-sided semi fiberglass 22F, CEM-1 and double-sided semi fiberglass board CEM-3, among which CEM-1 and CEM-3 are the most common composite base copper clad laminate.

3. Glass fiber PCB substrate

Sometimes it also becomes epoxy board, fiberglass board, FR4, fiberboard, etc. It uses epoxy resin as the adhesive and fiberglass cloth as the reinforcement. This kind of circuit board has a high working temperature and is little affected by the environment. It is often used in double-sided PCBs, but its price is relatively expensive compared with that of composite PCBs, with a common thickness of 1.6MM. This kind of substrate is suitable for various power boards, high layer circuit boards, and is widely used in computers, peripherals, communication equipment, etc.

4. Other substrates

In addition to the three types often seen above, there are also metal substrates and BUM.

PCB manufacturers, PCB designers and PCBA manufacturers will explain the differences between different materials of PCB boards in electronic engineering.