PCBA processing plant: types and common faults of SMT Feida

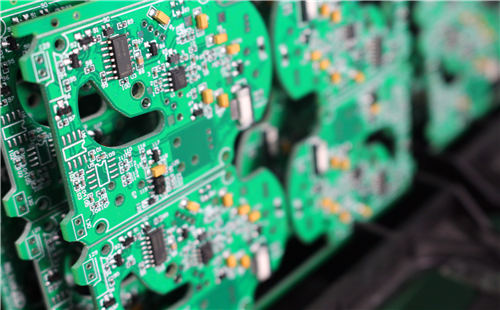

SMT Feida's English literal translation is Feeder, also known as feeder or feeder. The components for mounting can be installed on SMT Feida to provide components for the mounting machine for rapid mounting.

1、 SMT Feida type

1. According to the feeding method, the common ones are

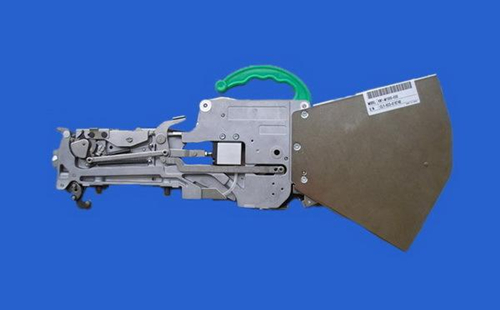

(1) Tape Feeder

The belt feeder is the most commonly used standard feeder in the feeder of the chip mounter. The traditional structure modes include wheel type, claw type, pneumatic type and multi pitch electric type. Now it has developed into high-precision electric type. Compared with the traditional structure mode, the high-precision electric type has higher transmission accuracy, faster feeding speed, more compact structure, more stable performance, and greatly improved the production efficiency.

The basic width of the strip material is 8mm, 12mm, 16mm, 24mm, 32mm, 44mm and 52mm, and the spacing is 2mm, 4mm, 8mm, 12mm and 16; There are 7 in. and 13 in. reel diameters.

(2) Tray Feeder

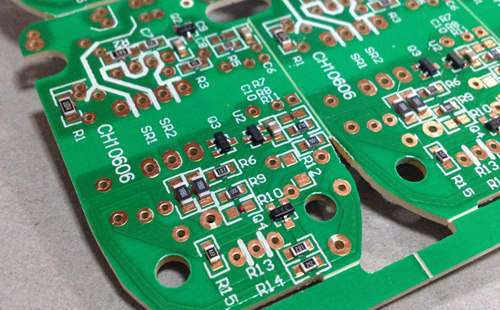

It can be divided into single-layer structure and multi-layer structure. The single-layer pallet feeder is directly installed on the feeder frame of the mounting machine, occupying multiple slots, and is applicable to the situation where there is not much pallet material; Multilayer tray feeder has multi-layer automatic transfer tray, which occupies small space and is compact in structure. It is applicable to the situation where there are many tray materials. The tray mounted components are mostly various IC integrated circuit components.

When using pallet type materials, it is necessary to protect the exposed components of large pipe corners to prevent damage to mechanical and electrical properties during transportation and use. When TQFP, PQFP, BGA, TSOP and SSOPs are used in the tray, the tray size can reach 150mm x 330.2mm and the height is 25.4mm. Interestingly, the tray feeder can not only supply the mounter to pick up components, but also serve as a potential throwing station for valuable components.

(3) Tube Feeder

The tube feeder usually uses a vibrating feeder to ensure that the components in the tube continuously enter the tip suction position. Generally, PLCC and SOIC are fed in this way. The tubular feeder has the characteristics of good protection for the pins of components, poor stability and standardization, and low production efficiency.

(4) Stick Feeder

Bulk box feeder, also known as vibrating feeder, works by freely loading components into molded plastic boxes or bags, and sequentially feeding components into the mounter through vibrating feeder or feeding tube. This method is usually used for MELF and small shape semi conductive components, only applicable to non-polar rectangular and cylindrical components, not polar components. Features: Vibration Feida is more expensive.

(5) Vibration Feeder

Special Feida needs to be customized. At present, the domestic ones are well done.

2. According to electric and non electric

Common ones are electric Feida and mechanical Feida

Yamaha's new SIGMA mounters are all electric Feida, and many of JUKI's Feida are mechanical Feida

2、 FAQs of SMT Feida (Yamaha Feida)

1. No tape winding

The main reason is that the one-way bearing inside the large reel pulley slips, which I think is a design defect. The three steel balls inside are very easy to wear, while the new one-way bearing is no longer a steel ball but a steel column.

2. Feida floats high

The alarm will be triggered due to the deviation of the reclaiming position, which will seriously damage the suction nozzle, so keep the Feida loading platform clean.

3. Feida does not feed

If the small spring on Feida falls off or breaks, and the gear gets stuck, it will fail to feed.

4. Feeding is not in place

There may be material residues in the gland or insufficient gland pressure.

During SMT chip production, SMT chip mounter will stop running due to the failure of SMT Feida and other accessories, which will lead to great losses. Therefore, we should try our best to ensure the normal feeding of Feida when processing the chip. PCB manufacturers, PCB designers and PCBA manufacturers will explain the types and common faults of SMT Feida.