Methods and Skills of PCB Cutting

PCB cutting is a PCB design However, many designers are reluctant to do this work because it involves sandpaper grinding (a harmful job) and drawing lines (a simple repetitive job). Even many designers believe that PCB cutting is not a scientific and technological work, and junior designers need little training to be competent for this work This concept has certain universality, but like many works, it is used to analyze PCB boards If designers master these skills, they can save a lot of time and greatly reduce labor Now we will discuss these knowledge in detail

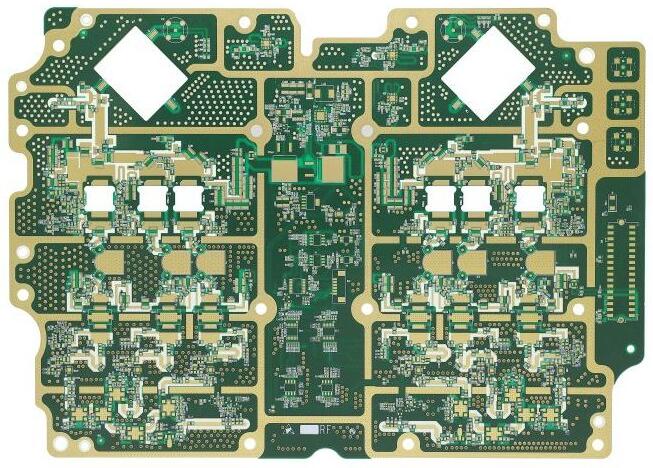

PCB board

First, the concept of PCB cutting

PCB profiling refers to the process of obtaining schematic diagrams and circuit board diagrams (PCB schematics) from the original PCB. Its purpose is to carry out later development. Later development includes installing components, deep testing and modifying circuits. Because it does not belong to and is related to PCB cutting, it is only an introduction and will not be described in detail.

2. Process PCB cutting

1. Remove the device from the original board.

2. Scan the original board to get the graphic file.

3. Grind off the surface layer to obtain the intermediate layer.

4. Scan the middle tier to obtain graphic files.

5. Repeat steps 2-4 until all layers are processed.

6. Use the special software to convert the graphic file into the power relationship file - PCB board diagram. If appropriate software is available, designers need to track the drawing only once.

7. Check and complete the design.

Third, PCB cutting skills

Copying PCB boards, especially multilayer PCB boards, is a time-consuming and labor-intensive work, which includes a lot of repetitive work. The designer must be patient and careful, otherwise it is easy to make mistakes. The key to the design of special-shaped PCB is to replace manual repetitive work with appropriate software, which is both time-saving and accurate.

1) Make sure to use the scanner during the cutting process.

Many designers are used to drawing lines directly on PCB design systems (such as PROTEL, PADSOR or CAD). This habit is very bad. The scanned graphic files are not only the basis for converting to PCB files, but also the basis for future inspection. The use of scanners can greatly reduce the difficulty and intensity of labor. It is no exaggeration to say that if the scanner can be fully utilized, even people without design experience can complete PCB cutting.

2) One way grinding plate.

In pursuit of speed, some designers choose to grind the circuit board from two directions (i.e., from the front and rear surfaces to the middle layers). In fact, this is very wrong. Because the two-way grinding plate is easy to wear through, causing damage to other layers, the results can be imagined. Due to the existence of process, copper foil, bonding pad, etc., the outer layer of PCB is hard while the middle layer is soft. In the middle layer, the problem is more serious, and polishing is often impossible. In addition, PCB boards produced by different manufacturers have different data, hardness and elasticity, so it is difficult to grind accurately.

3) Select the conversion software.

The key to the whole work is to convert scanned graphics files into PCB files Have good conversion files The designer only needs to "draw a tiger like a cat" and draw a figure once to complete the work

The above is the explanation given by the editor of pcb circuit board company. If you want to know more about PCBA, you can go to our company's home page to learn about it. In addition, our company also sells various circuit boards,

High frequency circuit board and SMT chip are waiting for your presence again.