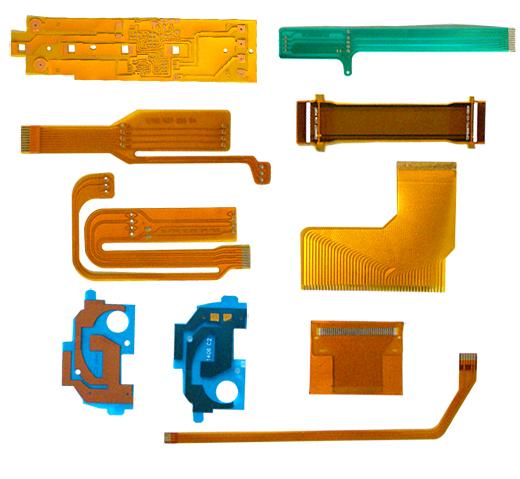

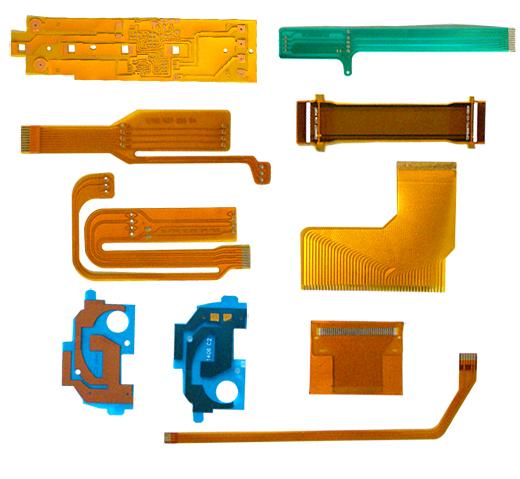

Detailed explanation of classification knowledge of single-sided soft PCB

PCB manufacturers and PCB designers explain the classification of single-sided soft PCBs

A single-sided flexible PCB has only one layer of conductor, and the surface can be covered or not covered. The insulating substrate materials used vary with the application of products. The commonly used insulating materials are polyester, polyimide, polytetrafluoroethylene, soft epoxy glass cloth, etc.

Single sided flexible PCB can be divided into the following four categories in detail:

1) Single sided soft PCB without covering layer

The wire pattern of this kind of flexible PCB is on the insulating substrate, and there is no covering layer on the wire surface. Like the common single-sided rigid PCB. This kind of product is the cheapest one and is usually used in non critical and environmental protection applications. The interconnection is realized by tin welding, fusion welding or pressure welding. It was often used in early telephone sets.

2) Single sided soft PCB with covering layer and single sided connection

Compared with the former type, this type only has an additional layer of coating on the conductor surface according to the customer's requirements. The pad shall be exposed when covering, and it can be simply not covered in the end area. Clearance holes can be used if precision is required. It is one of the most widely used single-sided soft PCBs, and is widely used in automotive instruments and electronic instruments.

3) Single sided soft PCB with double-sided connection without covering layer

Such connectors can be connected on the front and back of the wire. In order to achieve this, a passage hole is opened on the insulating substrate at the bonding pad. This passage hole can be punched, etched or made by other mechanical methods at the required position of the insulating substrate. It is used for mounting elements and devices on both sides and where soldering is required. There is no insulating substrate in the pad area at the path. Such pad areas are usually removed by chemical methods.

4) Single sided soft PCB with overlay and double-sided connection

The difference between this type and the previous type is that there is a layer of coating on the surface. However, the covering layer has access holes, which can also be terminated on both sides and still maintain the covering layer. This kind of flexible PCB is made of two layers of insulating material and one layer of metal conductor. It is used in situations where the covering layer needs to be insulated from the surrounding devices, and the end needs to be connected to both the front and the back.