Solder paste selection for PCB process

I found some data and also asked some experts. It turns out that there is so much knowledge about solder paste. I thought it would be enough to simply adjust the reflow profile to see whether the solderability is good. I didn't expect it to be so simple.

As the electronic parts used by the company are getting smaller and smaller, 0402 is the least used at present. As for 0201, I dare not use it. I'm afraid it will short circuit in a high humidity environment. Moreover, the company's products must pass the high temperature and high humidity ring test, so the selected solder paste must pay special attention to the performance of the SIR (Surface Insulation Resistance) value.

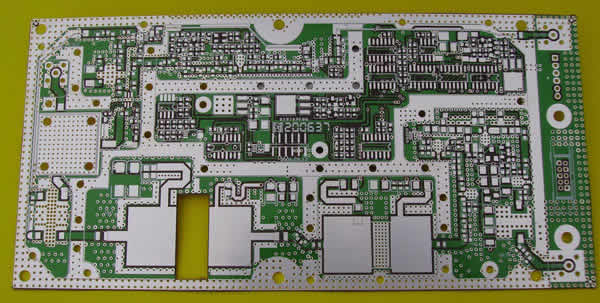

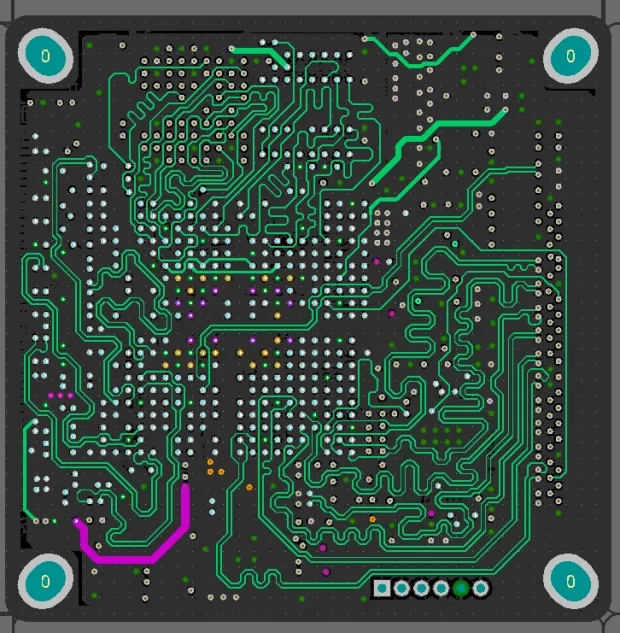

In fact, the quality of solder paste will directly affect the solderability quality of electronic products. Because almost all electronic parts now follow the SMT (Surface Mount Technology) process and are linked to the circuit board (PCB) through the solder paste, it is very important to select a suitable tin height for the company's products.

To judge the quality of solder paste, in addition to its solderability and slump resistance, the following items are the characteristics I think a good solder paste must have, and the solder paste manufacturer should also provide these test items for customers' reference. Of course, it would be better if you could choose some items to test yourself to prove that the manufacturer's solder paste is really as good as they claim.

SIR (Surface Insulation Resistance)

Electromigration

[Electron migration] The phenomenon is that when there is a potential difference between two adjacent ends, metal conductive substances (such as tin, silver, copper, etc.) grow from one end of the electrode to the other in a nerve plexus like manner. The medium in which it grows is a conductor, so if the flux has a slight conductivity and there are two adjacent ends, it is easy to produce electron migration, especially in high temperature and high humidity.

Corrosion test

Solder paste is printed on bare copper plate and then placed in an environment of 40 ° C+93% RH (humidity) for 10 days after reflow soldering, and then the corrosion condition is observed.

Ionic pollution

Wetting test (IPC J-STD-005)

Solder ball tset (IPC J-STD-005)

Strictly speaking, there are two types of tin balls, one is micro solder ball, and the other is solder bead.

The causes of typical micro solder balls are:

The solder paste collapses outside the solder pad. When the solder paste is reflowed, the solder paste collapsed outside the solder pad cannot return to the solder joint to form satellite solder balls.

The flux quickly escapes during reflow and takes the solder paste out of the solder pad. If the solder paste powder is oxidized, it will be more serious.

Oxidation resistance of solder paste

If it is a small and diverse production line, the production process needs to change the line frequently. After changing the line, it will need to confirm the quality of solder paste printing, as well as adjust the machine. The solder paste often needs to wait for a period of time after printing before entering the reflow furnace. At this time, the oxidation resistance of the solder paste will become very important.

Slump test (IPC J-STD-005)

The collapse test is generally used to test the fine pitch Printability of solder paste on the fine pitch parts. The 0.5mm pitch is called fine pitch, and the 0.4mm pitch is called super Fine Pitch. In addition, it can also help to check the time that the solder paste can stay after printing and before reflow soldering.

The test method is to place the solder paste at room temperature of 25+/- 5C for 20 minutes after printing, check the collapse condition first, then heat it to 180C for 15 minutes, wait until it cools down, check the collapse condition of the solder paste once, and then check and record it again in the next 2 hours and 4 hours, preferably with photos.

In addition, the following are the items I think I can do when evaluating a new solder paste

Solder bead rate

Solder ball rate

Solder bridge rate

Welding ability

Testability issues to consider

Flux residue rate and ICT (In Circuit Tester) fault reject rate.

When too much flux is left on the solder pad on the circuit board, the false judgment rate of ICT will increase, because the flux will block the contact between the test needle and the test point on the circuit board. In addition, the residual flux between the solder pad and the solder pad of the circuit board may also cause electron migration under high temperature and humidity, and then cause slight electric leakage. Over time, electronic products will have unstable quality. If it occurs on the battery circuit, it will cause electricity eating. Of course, this leakage phenomenon depends on the size of the surface impedance (SIR) of the flux.