In clinical practice, many medical devices play a key role in saving patients. These medical devices include oximeters, ventilators, mobile CT, patient monitors, extracorporeal membrane oxygenation (ECMO). With the outbreak of the epidemic at home and abroad, the demand for these medical devices is increasing. Therefore, the urgent demand for medical PCBs is also growing.

Due to the special importance of medical devices, the quality standard of medical PCBs is higher than that of PCBs in other industries. Safety, durability and accuracy are the most critical requirements for medical PCBs. Only PCB manufacturers with higher production levels can meet the requirements of medical PCBs. Next, we will explain the assembly requirements of the medical PCB and the analysis of the oximeter PCBA case.

Medical PCB assemblers are usually responsible for the PCB assemy portion of medical devices. But PCB assembly is indeed not an easy task, it requires a lot of skills and knowledge.

Advanced automation equipment

Most medical devices are made up of small components, requiring medical PCB assemblers to be able to handle these tiny, complex parts and fit them together precisely. An automatic production line with advanced equipment is the guarantee of production accuracy.

Professional engineers and operators

In addition to high-end machines, professional employees are also the key to high-quality manufacturing. Because PCB manufacturing and PCB assembly are very professional and have complex processes in production. All production links from PCB design, PCB manufacturing, PCB testing and other steps are inseparable from the control of skilled engineers.

Good Manufacturing Practice (GMP)

Good production practices are not only the guarantee of safe production, but also the guarantee of product quality and production efficiency. Medical devices have an incredible impact on our daily lives and are extremely important to patients. Therefore, PCB manufacturers must practice good personal hygiene to prevent any potential contamination or defects.

Strict quality control system

Medical devices help patients diagnose disease and improve quality of life. Based on this special role, Medical PCB Assemblies should enable products to maintain excellent quality standards. PCB manufacturers need to have sufficient understanding of the details of the manufacturing process and spot potential errors. Strict quality control procedures are conducive to the actual and accurate quality inspection of products.

Oximeter

The oximeter is used to detect blood oxygen. Monitoring blood oxygen is a non-invasive operation. It can effectively monitor the blood oxygen in the body and play a key role in predicting changes in the condition. The main measurement indicators of the oximeter are pulse rate, blood oxygen saturation, and perfusion index (PI).

Problems encountered in assembling the oximeter:

1. There are many types of oximeters sold to various countries, and different programs and languages need to be programmed. Multiple programs in the same batch of orders need to be marked differently on the MCU, which is very important;

2. The soldering of the cable of the oximeter display requires thick tin and high temperature, otherwise the part of the cable will be badly tinned;

3. The assembly of the oximeter shell needs to control the height of the photoelectric sensor components. Before soldering, the component needs to be formed and cut according to the specified height, otherwise the shell cannot be fastened if it exceeds the height.

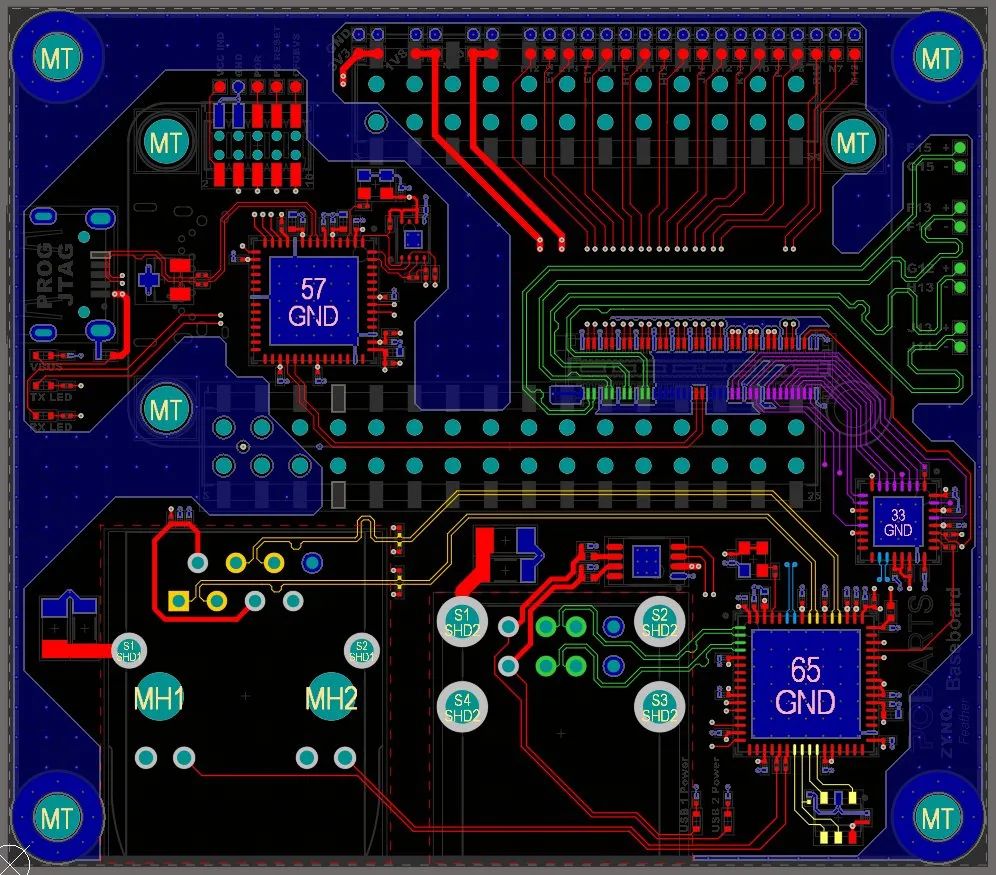

Specifications

Product Name: Oximeter Integrated Finger Clip

Main control chip model: STM32

Material: FR4

Layers: 2-4Layers

Plate thickness: 1.6mm

Application Field: Medical Electronics Field

The miniaturization and packaging diversity of electronic components, the complex process, high-density interconnection (HDI) and high pass-through yield (FPY) brought about by the high reliability requirements of electronic components (PCBA), while the MES or ERP system electronics The high and excessive distribution of process defects presented on the checklist or Plato on the visual screen puts pressure on the factory managers. To this end, we must carry out comprehensive process control for every link and operation step in the SMT and THT production process, optimize the DFMA design and FMEA of PCB and components, and do a good job in NPI review, and strive to do it right the first time, do a good job Supplier management and incoming inspection of components and auxiliary materials, fixture first article inspection (FAI) and CPK audit.

Printed circuit boards (PCBs) play an important role in healthcare and medicine. As the industry continues to innovate to bring the best technology to patients and their caregivers, more and more research, treatment and diagnostic strategies are moving towards automation. Therefore, more jobs involving PCB assembly are needed to improve medical devices in the industry.

As the population ages, the importance of PCB assembly in the medical industry will continue to grow. Currently, PCBs play an important role in medical imaging equipment such as MRIs and cardiac monitoring equipment such as pacemakers. Even temperature monitoring devices and responsive neurostimulators can be implemented with state-of-the-art PCB technology and components. Today, the editor specially invited the technical staff of Jeddobang to discuss with you the role of PCB assembly in the medical industry.

mobile health

With the advancement of PCB assembly technology, traditional wires and flexible wires have quickly become a thing of the past. In the past, traditional electrical outlets were often used for plugging and unplugging cords and cords, but modern medical innovations allow doctors to care for patients anytime, anywhere.

In fact, the mHealth market was estimated to be worth more than $20 billion as early as the year before last, with smartphones, iPads and other such devices enabling healthcare providers to easily receive and transmit vital medical information as needed. Thanks to advances in mobile medicine, you can better help patients by filling out documents, ordering equipment and medications, and researching certain symptoms or conditions with just a few mouse clicks.

implantable medical device

The use of PCB assembly becomes even more complicated when it comes to implantable medical devices because there is no uniform standard that makes all PCB assemblies compliant. In other words, different implants will achieve different goals under different medical conditions, and the instability of implants will also affect the design and manufacture of PCBs. In any case, a well-designed PCB can enable deaf people to hear with cochlear implants. Some for the first time in their lives.

What's more, patients with advanced cardiovascular disease could benefit from implanted defibrillators because they may be more vulnerable to sudden and unexpected cardiac arrest, which can occur anywhere or Caused by trauma.

Electronic Health Record

In the past, integration of electronic health records has been poor, with many electronic records lacking connectivity of any kind. Instead, each system is a separate system that handles orders, documents, and other tasks in an independent manner. Over time, these systems have been integrated to form a more comprehensive picture, which has allowed the healthcare industry to expedite patient care and greatly increase efficiency.

Tremendous progress has been made in integrating patient information. However, as the future ushers in a new era of data-driven healthcare, the potential for further development is almost limitless. In other words, electronic health records will be used as a modern tool to enable the medical industry to collect data about the population; making it permanent to improve medical success and effectiveness.