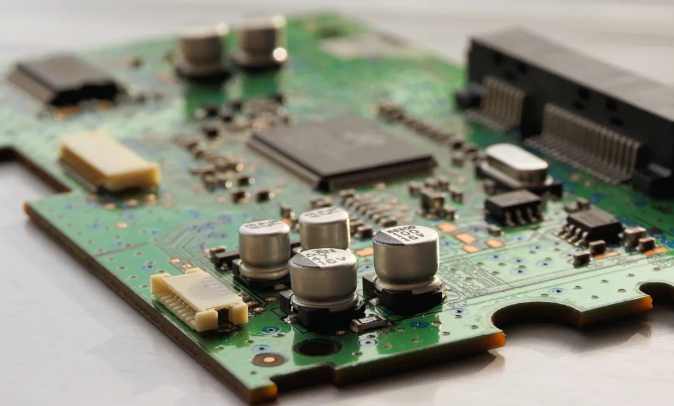

False welding, also called false welding, is a state of disconnection. It is a kind of poor welding, which is a very important reason for the high repair rate in the early stage of PCBA. Next, Shenzhen PCBA processing manufacturer - Shenzhen kingford will introduce the reasons for the appearance of virtual welding in PCBA processing.

Causes of virtual welding in PCBA processing

1. Oxidation of pad and element pins

The oxidation of pad and component pins can easily lead to the liquefaction of paste during reflow welding, the pad cannot be sufficiently wet, and the solder will crawl, resulting in virtual welding.

2. Less tin

In the solder paste printing process, the steel mesh hole is too small or the scraper pressure is too small, resulting in less tin output. When welding, the amount of welding paste is insufficient, the components can not be completely welded, resulting in virtual welding.

3. The temperature is too high or too low

In addition to the temperature is too low will cause virtual welding, temperature should not be too high. Because the temperature is too high, not only the solder flow, but also the surface oxidation speed. It may also cause false welding or no welding.

4. Low melting point of welding paste

For some low temperature solder paste, the melting point is relatively low, the component pin and the fixed component of the plate is different, the coefficient of thermal expansion is different. For a long time, with the change of the working temperature of the element, under the action of thermal expansion and cold contraction, it will cause virtual welding.

5. Quality problem of tin paste

The solder paste is of poor quality. Solder paste is easy to oxidize, flux loss, directly affect solder paste welding performance, resulting in virtual welding.

Generally speaking, PCB welding is complicated, and strict process control is needed in production to optimize the process flow.

2.PCBA manufacturer detailed PCBA proofing steps

Professional things are done by professional companies. In order to save cost and time, most electronics enterprises choose to give products to third-party PCBA manufacturers for production, and they will do PCBA proofing before mass production. So how does PCBA proofing work?

PCBA proofing operation process

1. Customer orders

Customers place orders to PCBA processing plants according to actual needs and put forward specific requirements. The PCBA processing plant will evaluate its own capacity to see if it can fulfill the order. If the PCBA manufacturer determines that he can complete the order within a certain time, then the two parties will negotiate the details of each production.

2. Production materials provided by customers

After the customer decides to place an order, the PCBA processing plant will provide a series of documents and lists such as PCB electronic files, coordinate files and BOM lists required for production.

3. Procurement of raw materials

The PCBA processing plant procured the relevant raw materials from the specified supplier according to the documents provided by the customer.

4. Incoming material inspection

Before PCBA proofing, for all the raw materials used, PCBA processing plants need to pass strict quality inspection. Only after qualified can it be put into production.

5. PCBA production

In the PCBA proofing, in order to ensure the quality of production, whether it is patch production or welding production, PCBA processing manufacturers need to strictly control the furnace temperature.

6. PCBA test

PCBA processing plants also need to undergo rigorous testing, and only PCB boards that pass the test can be delivered to customers.

7. After-sales packaging

After PCBA proofing is completed, the products need to be packaged and then delivered to the customer to complete the whole proofing work.

Shenzhen kingfordPCBA processing advantages

1. Highly professional: The company focuses on processing samples and small and medium-sized batches, and promises to deliver the materials within 3-5 working days after confirmation.

2. Professional equipment: The company's equipment is tailored for sample and small and medium-sized batch production of advanced equipment, can stick 0201, BGA spacing 0.3MM, QFN, CSP, CON and other components.

3. Professional technology: 100% of technical backbone workers have more than 5 years of work experience, 85% of front-line operators have more than 3 years of work experience.

4. The company implements the 5S and 6σ concepts in daily operation, so as to ensure that the shipment is checked at least 7 times. If the quantity reaches 100PCS, our company promises to pass AOI optical inspection.

5. The company promises that the straight through rate of welding is more than 99%. If customers find welding defects, the company promises to repair them free of charge.

Choose Shenzhen kingford to do PCBA processing four reasons

1. Strength guarantee

▪SMT workshop: We have imported SMT machines and several sets of optical inspection equipment, with a daily output of 4 million. Each process is equipped with QC personnel, who can keep an eye on product quality.

▪DIP production line: We have two wave-soldering machines, among which there are more than 10 old employees who have worked for more than three years. The skilled workers can weld all kinds of plug-in materials.

2. Quality assurance, cost-effective

▪ High-end equipment can stick precision shaped parts, BGA, QFN, 0201 materials. Can also template patch, loose material hand.

▪ Sample and size batch can be produced, proofing from 800 yuan, batch 0.008 yuan/point, no start-up fee.

3. Rich experience in SMT and welding of electronic products, stable delivery

▪ Accumulated SMT SMT processing services for thousands of electronic enterprises, involving many kinds of automotive equipment and industrial control motherboard. The products are often exported to Europe and the United States, and the quality can be affirmed by new and old customers.

▪ On time delivery, normal 3-5 days after complete materials, small batch can also be expedited on the same day shipment.

4. Strong maintenance ability and perfect after-sales service

▪ Experienced maintenance engineers can repair all kinds of patch welding caused by bad products, to ensure the connection rate of each piece of circuit board.

▪ 24-hour customer service staff at any time response, the fastest speed to solve your order problems.