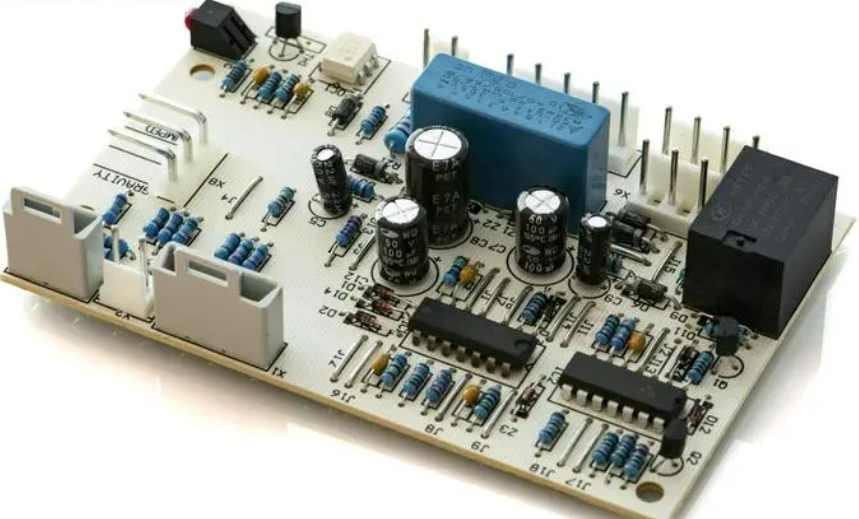

What we say to do is to turn the designed schematic into a real PCB circuit board. Please don't underestimate this process. There are many things that are feasible in principle but difficult to achieve in engineering, or others can achieve things that others can not achieve, so it is not difficult to make a good board, but it is not an easy thing to make a good PCB circuit board.

The two major difficulties in the field of microelectronics are the processing of high-frequency signals and weak signals, in this respect PCB production level is particularly important, the same principle design, the same components, different people produced PCB circuit boards have different results, so how to make a good PCB circuit board? Based on our previous experience, I would like to share my views on the following aspects:

First, to clear the design objectives

To receive a design task, first of all, it is necessary to clarify its design objectives, which are ordinary PCB circuit board, high frequency PCB board, small signal processing PCB board or both high frequency and small signal processing PCB board. If it is an ordinary PCB circuit board, as long as the layout and wiring are reasonable and neat, and the mechanical size is accurate, such as medium load line and long line, It is necessary to use certain means to deal with, reduce the load, long line to strengthen the drive, the focus is to prevent long line reflection.

When there are more than 40MHz signal wires on the board, special considerations must be made for these signal wires, such as cross-talk between wires and other issues. If the frequency is higher, there is a more strict limit on the length of the wiring. According to the network theory of distributed parameters, the interaction between high speed and its wiring is a decisive factor, which cannot be ignored in the system design. With the increase of the gate transmission speed, the opposition on the signal line will increase correspondingly, and the crosstalk between adjacent signal lines will increase in direct proportion. Usually, the power consumption and heat dissipation of high-speed circuits are also large, so sufficient attention should be paid to the high-speed PCB.

When there is a weak signal of millivolt level or even microvolt level on the board, special attention is needed for these signal lines. Small signals are too weak and very susceptible to interference from other strong signals. Shielding measures are often necessary, otherwise the signal-to-noise ratio will be greatly reduced. So that useful signals are drowned out by noise and cannot be effectively extracted.

The commissioning of the board should also be considered in the design phase, the physical location of the test point, the isolation of the test point and other factors can not be ignored, because some small signals and high frequency signals can not be directly added to the probe to carry out.

In addition, some other relevant factors should be considered, such as the number of layers of the board, the packaging shape of the components used, the mechanical strength of the board, etc. Before doing PCB board, to make the design of the design goal in mind.

Two, understand the function of the components of the layout and wiring requirements

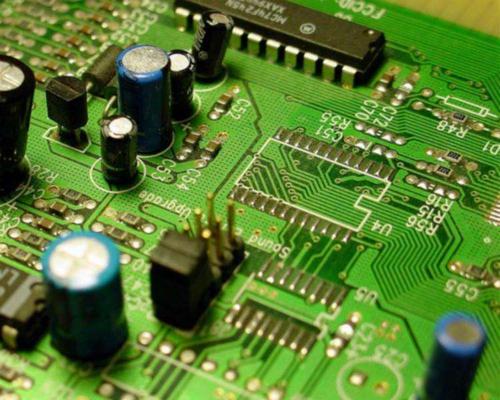

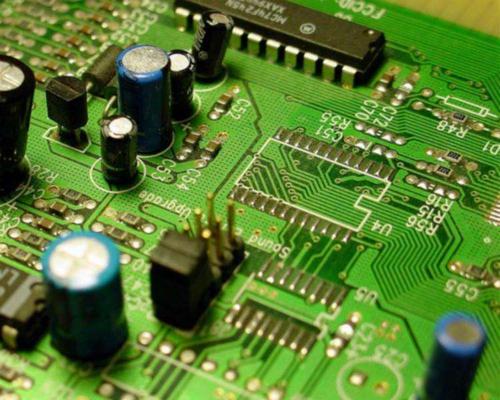

As we know, some special components have special requirements in the layout of wiring, such as LO and APH analog signals, analog signal amplifiers require stable power supply and small ripple. The analog small signal part should be far away from the power device as far as possible. On the OTI board, the small signal amplification part is also specially equipped with a shield to shield the stray electromagnetic interference. The GLINK chip used on the NTOI board uses the ECL process, high power consumption and severe heating, the heat dissipation problem must be in the layout must be special consideration, if the use of natural heat dissipation, it is necessary to put the GLINK chip in the place where the air circulation is smooth, and the heat out can not constitute a big impact on other chips. If the board is equipped with a horn or other high-power devices, it is possible to cause serious pollution to the power supply, which should also cause enough attention.

3. Consideration of component layout

One of the first factors to consider in the layout of components is the electrical performance. The components with close connection should be put together as far as possible, especially for some high-speed lines. The layout should make it as short as possible, and the power signal and small signal devices should be separated. On the premise of meeting the circuit performance, it is also necessary to consider that the components are placed neatly, beautiful, and easy to test. The mechanical size of the board and the location of the socket also need to be seriously considered.

The transmission delay time of ground and interconnect in high-speed system is also the first factor to be considered in system design. The transmission time on the signal line has a great impact on the overall system speed, especially on the high-speed ECL circuit. Although the block speed is very high, the system speed can be greatly reduced by the increase of the delay time brought by the common interconnect on the bottom plate (about 2ns delay per 30cm line length). Synchronous counter this kind of synchronous working part is best placed on the same plug-in board, because the signal transmission delay time to different plug-in boards is not equal, may make the shift register to produce the main error, if can not be placed on a board, in the synchronization is the key place, from the common clock source connected to the plug-in board clock line length must be equal.

Four, the consideration of wiring

With the completion of OTNI and star network design, there will be more boards with high speed signal lines above 100MHz to be designed in the future. Some basic concepts of high speed lines will be introduced here.

Transmission line

Any "long" signal path on a printed circuit board can be regarded as a transmission line. If the transmission delay time of the line is much shorter than the rise time of the signal, the reflection generated during the rise of the signal will be drowned. Overkick, recoil and ringing are no longer present. For most current MOS circuits, the line length can be measured in meters without signal distortion due to the much larger ratio of the rise time to the line transmission delay time. And for fast logic circuits, especially ultra-high speed ECLs.

In the case of integrated circuits, due to the increase in edge speed, if nothing else, the length of the line must be greatly reduced to maintain the integrity of the signal.