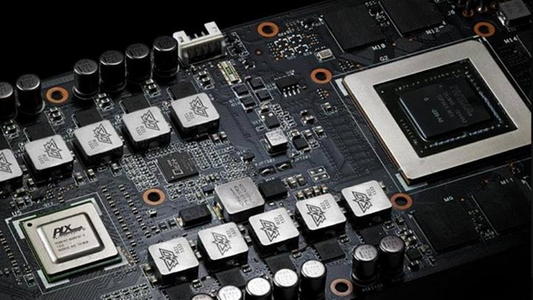

PCB boards have gained increasing use because they have many unique advantages, like this:

With high density: For more than 100 years, the high density of printed circuit board can be developed with the improvement of integrated circuit integration and installation technology.

With high reliability: through a series of inspection, test and aging test can ensure the long-term and reliable work of the circuit board.

It is designable; For various performance requirements of circuit board, printed board design can be realized through design standardization, standardization, etc., short time, high efficiency.

With productive: using modern management, can be standardized, scale (quantity), automation and other production, to ensure the consistency of product quality.

Testability: a relatively complete test method, test standards, various test equipment and instruments have been established to test and identify the circuit board product qualification and service life.

With assemblability: circuit board products are convenient for standardized assembly of various components, and can be automated, large-scale batch production. At the same time, the circuit board and various components assembly parts can also be assembled into larger parts, systems, until the whole machine.

Maintainability: Since circuit board products and various component assembly components are standardized in design and scale production, these components are standardized. So, once the system failure, can be quickly, convenient, flexible replacement, quickly restore the system work.

Circuit board short circuit inspection method

1, if it is manual welding, to develop a good habit, first of all, before welding to visually check the PCB board, and use a multimeter to check the key circuit (especially power and ground) is short circuit; Secondly, after each welding of a chip, use a multimeter to test whether the power supply and ground short circuit; In addition, do not toss the soldering iron when welding, if the solder is thrown to the welding foot of the chip (especially the table sticker components), it is not easy to find.

2. Open the PCB diagram on the computer, light up the short-circuit network, and see where it is closest and most easily connected. Pay special attention to IC internal short circuit.

3. Short circuit is found. Take a board to cut the line (especially suitable for single/double layer board), after the cut line will each part of the functional block power separately, part part of the exclusion.

Common fault analysis of circuit board

All kinds of good and bad electrical faults probably include the following situations:

First, poor contact: poor contact between the board card and the slot, the cable is broken when the internal through, wire plug and terminal contact is not good, components virtual welding, etc. The solution to this kind of failure is to carefully check the suspected connector, see if there is no obvious oxidation or bad contact phenomenon, scraping file oxidation metal contact point, toggle to adjust the position of the contact point, after handling the re-dial test contact is good.

Two, signal interference: for digital circuits, in a certain situation I drunk sleep, the fault will appear. It is possible that the interference is indeed too much to affect the control system to make it wrong, there are also individual component parameters on the printed board or the overall performance parameters have changed, so that the anti-interference ability tends to the critical point, resulting in failure. In this case, check whether the equipment is well grounded. Use a test pen to check whether the equipment shell is live, or use an AC meter to measure whether the equipment shell has a high voltage to the ground, which is generally less than 1V. If it is above 10V, it is necessary to doubt whether the grounding is good.

Three, the thermal stability of components is not good: from a large number of maintenance practices, the first is the thermal stability of electrolytic capacitor is not good, followed by other capacitors, triode, diode, IC, resistance, etc.

1, this kind of fault will generally accompany the machine boot time and appear or disappear, the essence is that the fault changes with the temperature of a fault element. For example, the fault caused by the aging of electrolytic capacitor is generally a failure just after power, and after a period of time, the fault disappears, that is, there is a fault in the cold machine, and there is no fault in the heat engine. Its essence is: the capacitance of aging electrolytic capacitor changes with the temperature, the temperature is low when the capacity is small, resulting in poor filtering, circuit board can not work normally, and with the power time long, the temperature of the electrolytic capacitor rises, the capacity increases, to meet the filtering conditions, so that the fault disappeared.

2, the thermal stability fault is a soft fault, maintenance is not easy to directly detect the fault components, but can be artificially suspected of components heating or cooling method to reduce the scope of inspection. A hair dryer or electric gun can be used to heat the suspect element, and a cotton swab dipped in alcohol can be used to cool the suspect element. The capacitance is easy to distinguish by VI curve test.

Four, there is moisture on the circuit board, dust, etc. : moisture and dust will conduct electricity, with resistance effect, and in the process of thermal expansion and contraction, the resistance value will change, the resistance value will be associated with other components, the effect is strong when it will change the circuit parameters, so that the fault occurs.

This kind of fault can be solved by cleaning the circuit board. It is recommended to use board washing water to clean the circuit board, or directly use water to clean it, and then use a hair dryer to dry it thoroughly. Alcohol is not recommended, as it tends to leave some white material on the board after cleaning.

Five, software is also one of the factors to consider: many parameters in the circuit to use software to adjust, the margin of some parameters is too low, in the critical range, when the machine operating conditions in line with the software to determine the fault, then the alarm change will appear.

This fault can be rectified by adjusting related parameters. For example, if the acceleration and deceleration time of the frequency converter is set improperly, there may be over and over load alarm during operation; CNC processing parameters are set improperly, processing products may not meet the requirements, encountered in these cases, the first time to suspect the problem of parameter setting, exclude the possibility of improper parameter setting to suspect the problem of the equipment itself.

Circuit board is good or bad judgment method

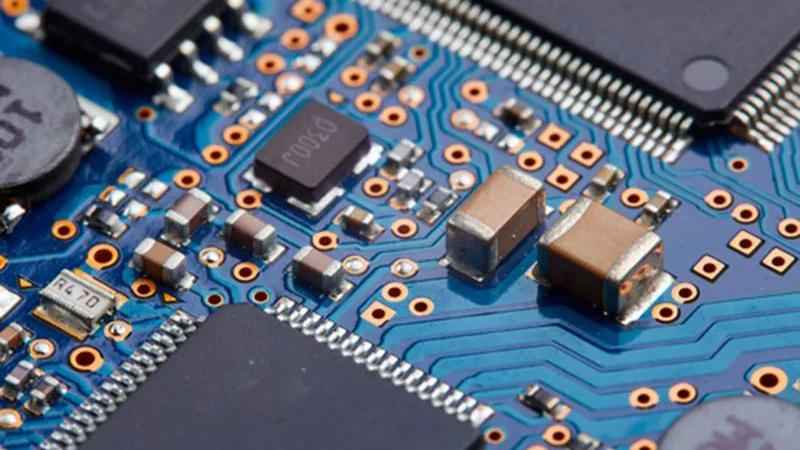

First: Distinguish from the appearance of the circuit board is good or bad in general, the appearance of the PCB circuit board can be analyzed and judged through three aspects:

1. Standard rules for size and thickness.

The thickness of the circuit board to the standard circuit board is different sizes, customers can measure and check according to their own product thickness and specifications.

2. Light and color.

External circuit boards are covered with ink, circuit boards can play the role of insulation, if the color of the board is not bright, less ink, insulation board itself is not good.

Second: high-quality PCB circuit boards need to meet the following requirements

1, line width, line thickness, line distance meet the requirements, so as to avoid line heating, open circuit, and short circuit.

2, the high temperature copper skin is not easy to fall off.

3, copper surface is not easy to oxidize, affect the installation speed, oxidation after use soon after bad.

4. No additional electromagnetic radiation.

5, the shape is not deformed, so as to avoid the deformation of the shell and dislocation of the screw hole after installation. Now the installation is mechanized, the hole position of the circuit board and the deformation error of the circuit and the design should be within the allowable range.

6, and high temperature, high humidity and special environment should also be considered in the range.

7, the mechanical properties of the surface should meet the installation requirements