Edit and explain the basic knowledge of SMT patch red glue

Basic knowledge

SMT patch red glue is a kind of polydilute compound, which is different from solder paste in that it will solidify after being heated, and its freezing point temperature is 150 ℃. At this time, the red glue starts to directly change from paste to solid.

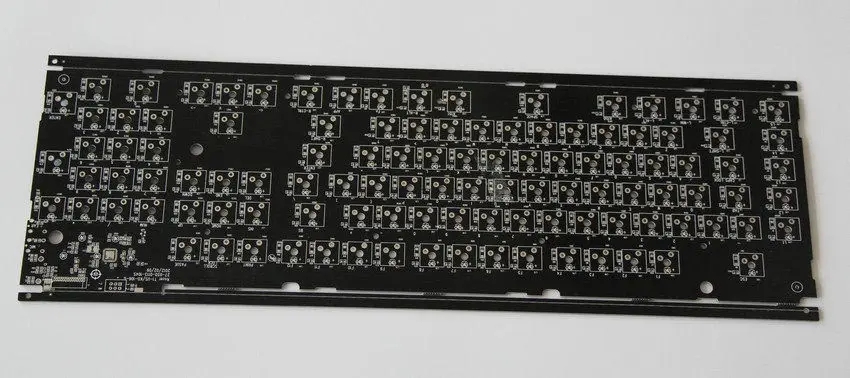

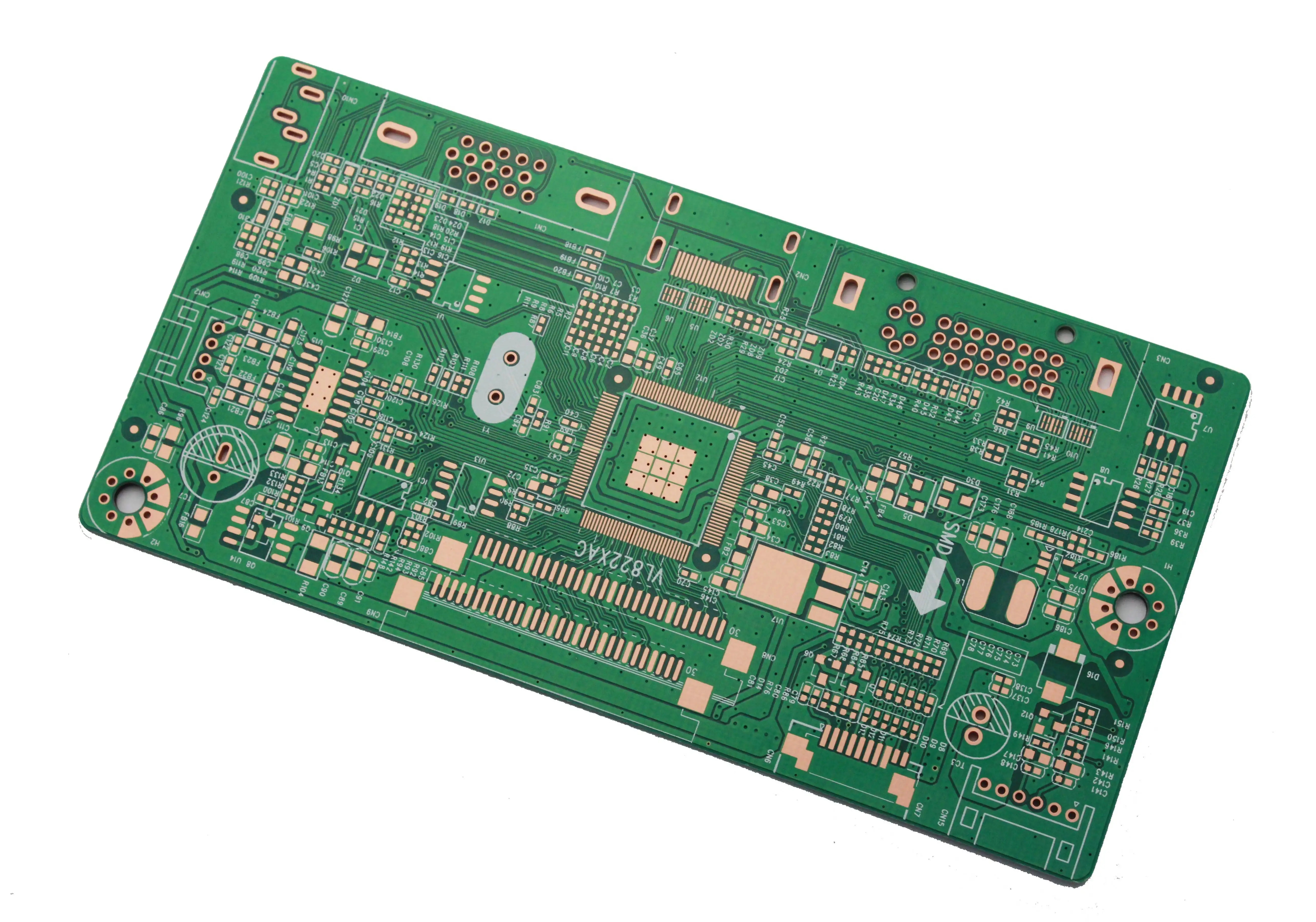

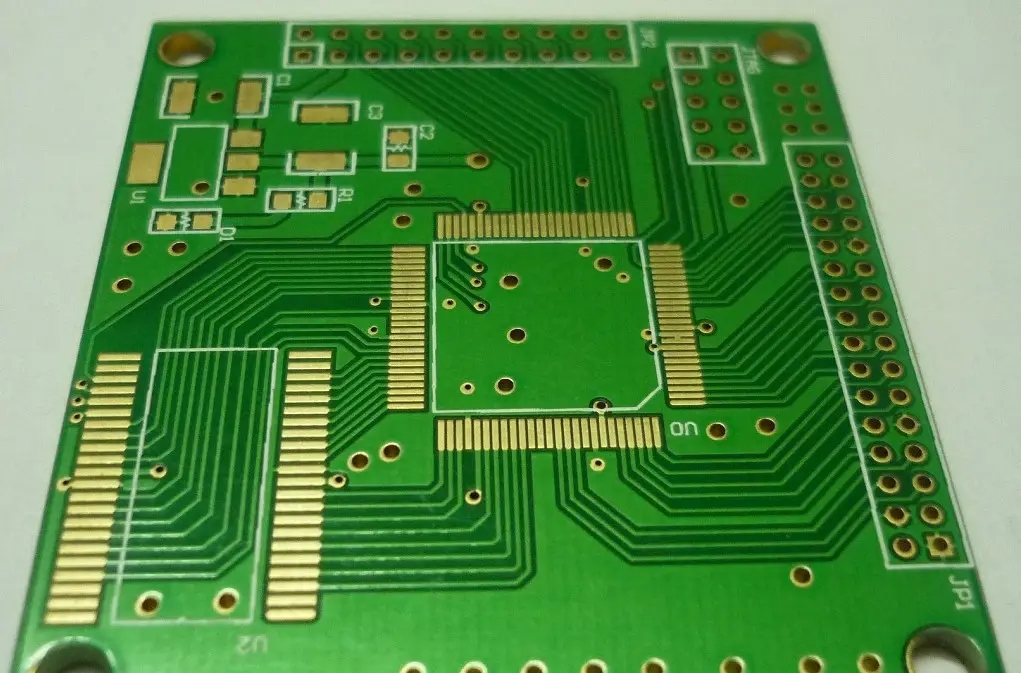

SMT patch red glue has viscosity fluidity, temperature characteristics, wetting characteristics, etc. According to this characteristic of red glue, the purpose of using red glue in production is to make the parts stick firmly on the PCB surface to prevent them from falling.

For use on printing machine or dispensing machine:

1. To maintain the quality of the patch adhesive, please store it in the refrigerator (5 ± 3 ℃);

2. Before taking it out of the refrigerator for use, it should be kept at room temperature for 2-3 hours;

3. Toluene or ethyl acetate can be used to clean the rubber hose for dispensing:

① Adding a back stopper in the dispensing tube can obtain a more stable dispensing amount;

② The recommended dispensing temperature is 30-35 ℃;

③ Please use a special glue dispenser to separate the rubber hoses to prevent the glue

Bubble glue scraping in water: the recommended glue scraping temperature is 30-35 ℃ Precautions: red

After the glue is removed from the cold storage environment, it cannot be opened for use until it reaches the room temperature. To avoid contamination

When dyeing the original packaging products, any used patch adhesive shall not be returned to the original packaging.

Printing method

1) Printing method: the steel screen engraving hole shall be determined according to the type of the part and the performance of the base material, its thickness and the size and shape of the hole. Its advantages are fast speed and high efficiency.

2) Dispensing method: using compressed air, the red glue is applied to the substrate through a special dispensing head. The size, number and size of the dispensing point are controlled by parameters such as time and pressure pipe diameter. The dispensing machine has flexible functions. For different parts, we can use different dispensing heads, set parameters to change, or change the shape and number of dispensing points to achieve the effect. The advantages are convenience, flexibility and stability. The disadvantage is that it is easy to have wire drawing and bubbles. We can adjust the operation parameters, speed, time, air pressure and temperature to minimize these shortcomings.

3) The needle rotation method is to immerse a specially made needle film into a shallow glue tray, and each needle has a glue point. When the glue point contacts the substrate, it will be separated from the needle. The glue amount can be changed by the shape and diameter of the needle. Curing temperature 100 ℃ 120 ℃ 150 ℃ Curing time 5 minutes 150 seconds 60 seconds Typical curing conditions: Notes:

1. The higher the curing temperature and the longer the curing time, the stronger the bonding strength.

2. Since the temperature of the patch adhesive will vary with the size and mounting position of the substrate parts, we suggest to find the most appropriate hardening conditions. Storage of red glue: it can be stored for 7 days at room temperature, more than 6 months at less than 5 ℃, and more than 30 days at 5~25 ℃.

Due to the viscosity, fluidity, wetting and other characteristics of SMT patch red adhesive affected by temperature, SMT patch red adhesive must have certain use conditions and standardized management.

1) The red glue shall have a specific serial number, which shall be numbered according to the quantity, date and type of incoming materials.

2) The red glue shall be stored in a refrigerator at 2~8 ℃ to prevent its characteristics from being affected by temperature changes.

3) The red glue shall be heated for 4 hours at room temperature, and used in the first in first out order.

4) For dispensing operation, the red glue in the rubber tube shall be de bubbled, and the red glue that is not used up at one time shall be put back into the refrigerator for storage. Old glue and new glue cannot be mixed.

5) The temperature recovery record form, temperature recovery person and time shall be filled in accurately. The user shall confirm the completion of temperature recovery before use. Generally, the expired red glue cannot be used.

Circuit board manufacturing, circuit board design, PCBA processing manufacturers will explain the basic knowledge of SMT patch red glue for you to edit.