Explanation of the first half of common knowledge of surface mount technology

1. Generally speaking, the temperature specified by SMT workshop is 23 ± 7 ℃;

2. Materials and tools required for solder paste printing: solder paste, steel plate, scraper, wiping paper, dust-free paper, cleaning agent, stirring knife;

3. The commonly used solder paste composition is Sn96.5%/Ag3%/Cu0.5%;

4. The main components of solder paste are divided into two parts: tin powder and flux;

5. The main role of flux in welding is to remove oxides, destroy the surface tension of molten tin and prevent reoxidation;

6. The volume ratio of tin powder particles in the solder paste to Flux (flux) is about 1:1, and the weight ratio is about 9:1;

7. The use principle of solder paste is first in first out;

8. When the solder paste is opened for use, it must go through two important processes of warming and stirring;

9. Common production methods of steel plate are: etching, laser, electroforming;

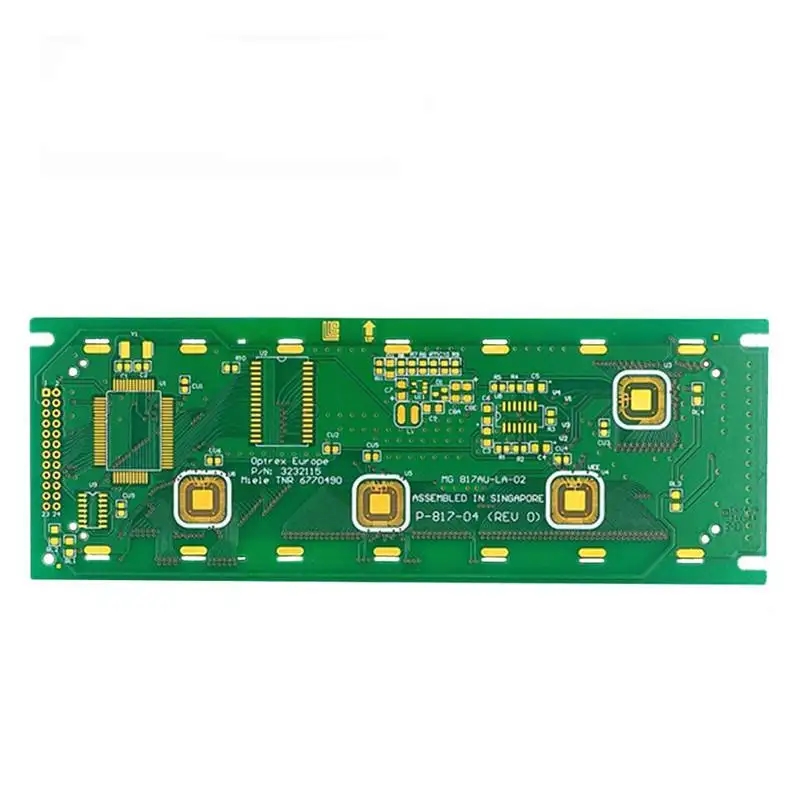

10. The full name of SMT is Surface mount (or mounting) technology, which means surface adhesion (or mounting) technology in Chinese;

11. The full name of ESD is Electro static discharge, which means electrostatic discharge in Chinese;

12. When making SMT equipment program, the program includes five parts, which are PCB data; Mark data; Feeder data; Nozzle data; Part data;

13. The melting point of lead-free solder Sn/Ag/Cu 96.5/3.0/0.5 is 217C;

14. The relative temperature and humidity of the tube of the parts drying oven are<10%;

15. Common passive devices include resistance, capacitance, inductance (or diode), etc; Active Devices include transistor, IC, etc;

16. The commonly used SMT steel plate is made of stainless steel;

17. The thickness of commonly used SMT steel plate is 0.15 mm (or 0.12 mm);

18. The types of electrostatic charges include friction, separation, induction, electrostatic conduction, etc; The influence of electrostatic charge on electronic industry is: ESD failure, electrostatic pollution; The three principles of electrostatic elimination are electrostatic neutralization, grounding and shielding;

19. Inch length x width 0603=0.06inch * 0.03inch, metric length x width 3216=3.2mm * 1.6mm;

20. Code 8 "4" of ERB-05,604-J81 refers to 4 circuits with resistance value of 56 ohms. Capacitance ECA-0105Y-M31: C=106PF=1NF=1X10-6F;

21. The full Chinese name of ECN is: Engineering Change Notice; The full Chinese name of SWR is: special needs worksheet, which must be countersigned by relevant departments and distributed by the Document Center, is valid;

22.5S includes sorting, rectification, cleaning, cleaning and accomplishment;

23. The purpose of PCB vacuum packaging is to prevent dust and moisture;

24. The quality policy is: comprehensive quality control, implementing the system, and providing the quality required by customers; Full participation and timely handling to achieve the goal of zero defect;

25. The "three no's" policy for quality: no acceptance of defective products, no manufacturing of defective products, and no outflow of defective products;

26. The seven QC techniques refer to checklist, layer method, Plato, causality diagram, scatter diagram, histogram and control diagram;

27. The solder paste consists of metal powder, solvent, flux, anti sag agent and active agent; By weight, metal powder accounts for 85-92%, and by volume, metal powder accounts for 50%;

28. The solder paste must be taken out of the refrigerator for temperature recovery when it is used. The purpose is to restore the temperature of the refrigerated solder paste to normal temperature for printing. If the temperature does not return, the defects that are easy to occur after PCBA enters Reflow are tin beads;

29. The document supply modes of the machine include: preparation mode, priority exchange mode, exchange mode and quick connection mode;

30. PCB positioning methods of SMT include vacuum positioning, mechanical hole positioning, bilateral clamp positioning and board edge positioning;

31. For resistance with silk screen (symbol) of 272, the resistance value is 2700 Ω, and for resistance with resistance value of 4.8M Ω, the symbol (silk screen) is 485;

32. The silk screen on the BGA body contains the manufacturer, manufacturer's part number, specification, Datecode/(Lot No) and other information;

33. The pitch of 208pinQFP is 0.5mm;

34. Among the seven QC techniques, fishbone diagram emphasizes the search for causality;

35. CPK refers to the process capability under actual conditions;

36. The flux starts to volatilize in the constant temperature zone for chemical cleaning;

37. Ideal mirror relationship between cooling zone curve and reflux zone curve;

38. Sn62Pb36Ag2 solder paste is mainly used for ceramic plate;

39. Rosin based flux can be divided into four types: R, RA, RSA, RMA;

40. RSS curve is temperature rise → constant temperature → reflux → cooling curve;

41. Our current PCB material is FR-4;

42. PCB warpage specification shall not exceed 0.7% of its diagonal;

43. Laser cutting made by STENCIL can be reworked;

44. The common BGA ball diameter on the computer motherboard is 0.76mm;

45. ABS system is absolute coordinate;

46. The error of ceramic chip capacitor ECA-0105Y-K31 is ± 10%;

47. The PCB of the computer used is made of glass fiber board;

48. The diameter of the tape reel for SMT part packaging is 13 inches and 7 inches;

49. In general, the opening of SMT steel plate is 4um smaller than that of PCB PAD, which can prevent the solder ball from being defective;

50. According to the PCBA Inspection Specification, when the dihedral angle is>90 degrees, it means that there is no adhesion between solder paste and wave soldering body;

51. When the humidity on the humidity display card after IC unpacking is greater than 30%, it means that the IC is damp and hygroscopic;

52. The correct weight ratio and volume ratio of tin powder and flux in solder paste composition are 90%: 10% and 50%: 50%;

53. The early surface mount technology originated from the military and avionics fields in the mid-1960s;

54. At present, the content of Sn and Pb in solder paste most commonly used by SMT is 63Sn 37Pb; The eutectic point is 183 ℃

55. The common paper tape tray with a bandwidth of 8mm has a feeding spacing of 4mm;

56. In the early 1970s, a new SMD appeared in the industry, which is a "sealed footless chip carrier", often replaced by LCC;

57. The resistance value of the component with symbol 272 shall be 2.7K ohms;

PCB manufacturing, PCB design and PCBA processing manufacturers will explain the first half of common knowledge of surface mounting process.