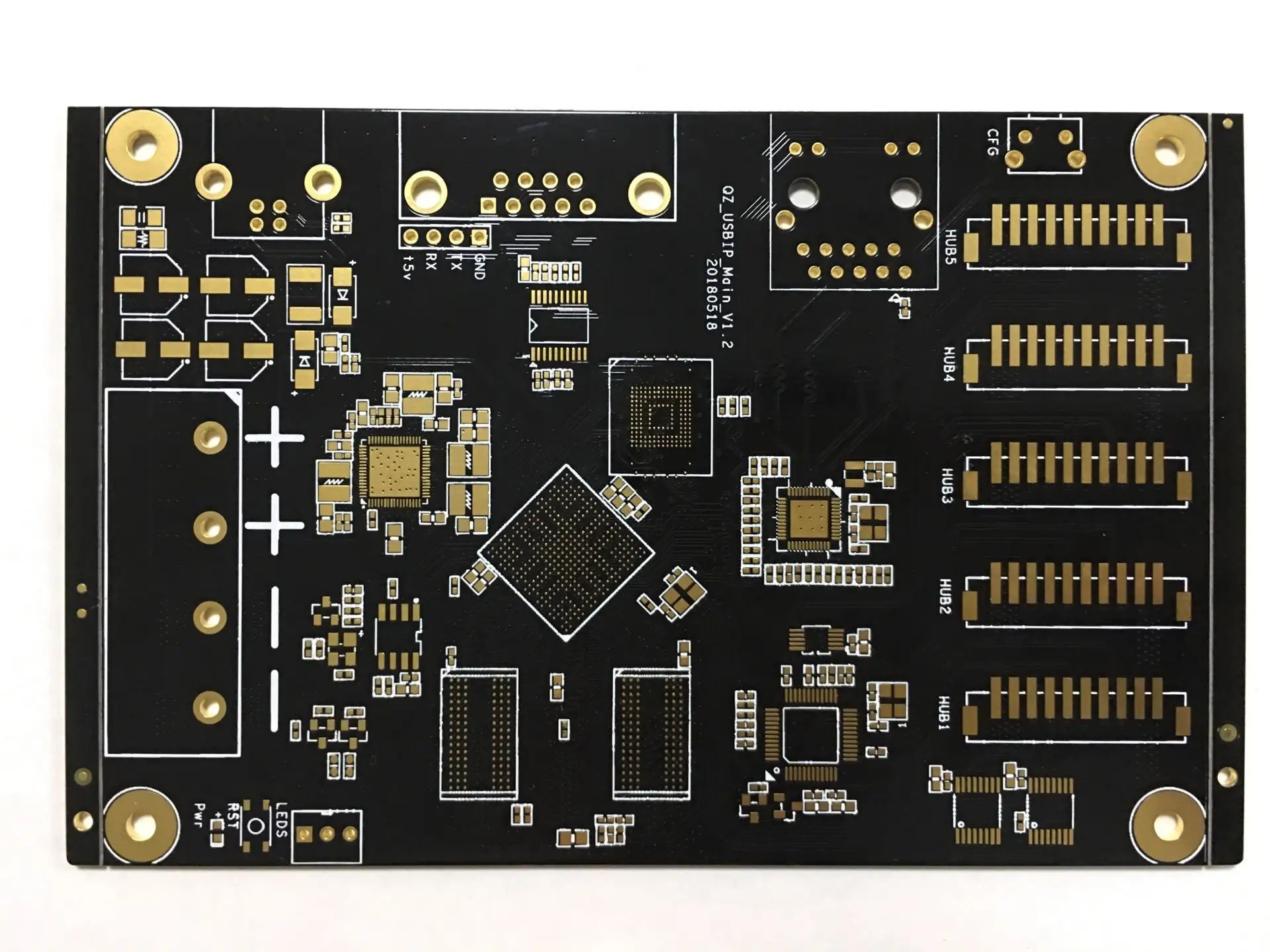

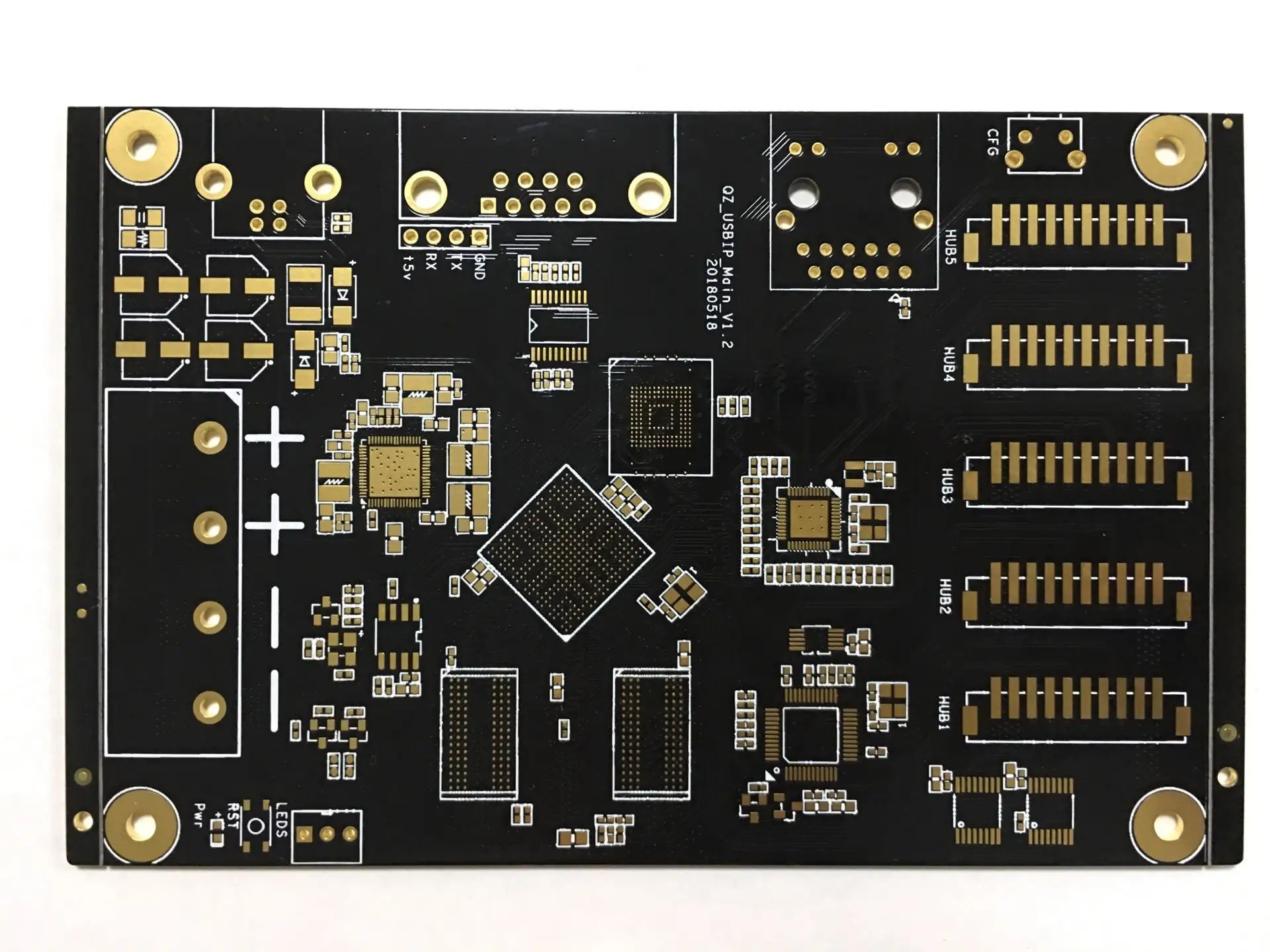

Process composition editing of SMT surface mounting technology of PCB

Circuit board manufacturing, circuit board design, PCBA processing manufacturers explain the process composition of SMT surface mounting technology for circuit boards

Printing (red glue/solder paste

The process flow is simplified as: printing ------ patch ------ welding ------ maintenance (each process can be added with a detection link to control the quality)

Solder paste printing

Its function is to skip the solder paste at a 45 degree angle to the PCB pad with a scraper, so as to prepare for the welding of components. The equipment used is a printing machine (solder paste printing machine), which is located at the front end of the SMT production line.

Parts mounting

Its function is to accurately install the surface mounted components on the fixed position of PCB. The equipment used is the mounting machine, which is located behind the printing machine in the SMT production line. Generally, high-speed machine and universal machine are used together according to production requirements.

Reflow soldering

Its function is to melt the solder paste, so that the surface mounted components and PCB are firmly welded together. The equipment used is a reflow soldering furnace, which is located behind the SMT mounter in the SMT production line. The requirements for temperature are quite strict, and real-time temperature measurement is required. The measured temperature is reflected in the form of profile.

AOI optical detection

Its function is to detect the welding quality of the welded PCB. The equipment used is automatic optical inspection machine (AOI), and the location can be configured in the appropriate place of the production line according to the needs of inspection. Some are before reflow soldering, and some are after reflow soldering.

repair

Its function is to repair the PCB detected to be faulty. The tools used are soldering iron, repair workstation, etc. Configured after AOI optical detection.

Splitting

Its function is to cut the PCBA of multiple connecting plates into individual pieces, generally using V-cut and machine cutting methods.

The circuit board manufacturer, circuit board designer and PCBA processor will explain the process composition and editing of SMT surface mounting technology for circuit boards.