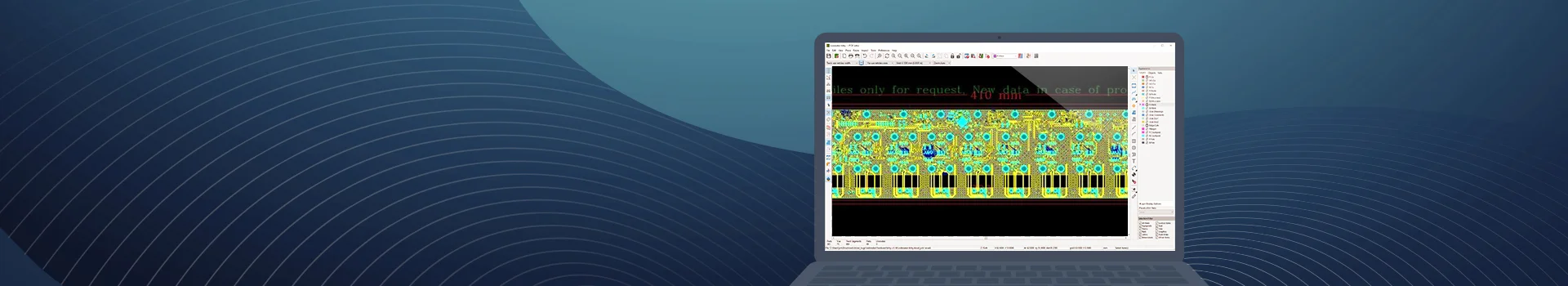

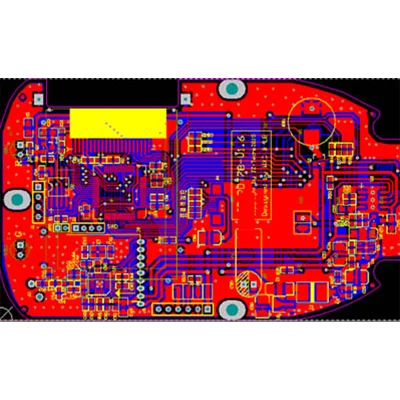

Rigid-flex PCB design for medical equipment

Name: Rigid-flex PCB design for medical equipment

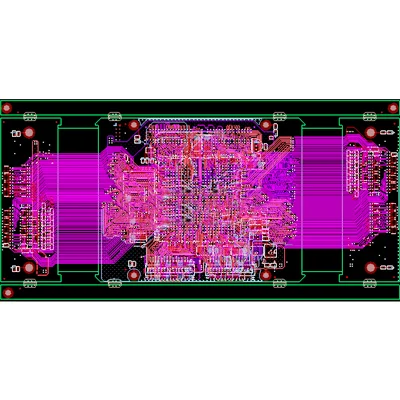

Designable layers: 1-32 layers

Minimum line width and line spacing: 3mil

Minimum laser aperture: 4mil

Minimum mechanical aperture: 8mil

Copper foil thickness: 18-175цm (standard: 18цm35цm70цm)

Peel strength: 1.25N/mm

Minimum punching hole diameter: single side: 0.9mm/35mil

Minimum hole diameter: 0.25mm/10mil

Aperture tolerance: ≤φ0.8mm±0.05mm

Hole tolerance: ±0.05mm

Hole wall copper thickness: double-sided/multi-layer: ≥2um/0.8mil

Hole resistance: double-sided/multi-layer: ≤300цΩ

Minimum line width: 0.127mm/5mil

Minimum pitch: 0.127mm/5mil

Screen printing color: black, white, red, green, etc.

Surface treatment: lead/lead-free tin spray, ENIG, silver, OSP

Service: Provide OEM service

Certificate: ISO9001.ROSH.UL

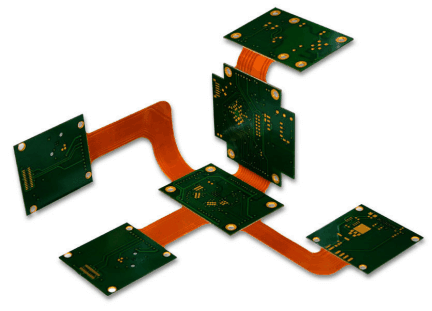

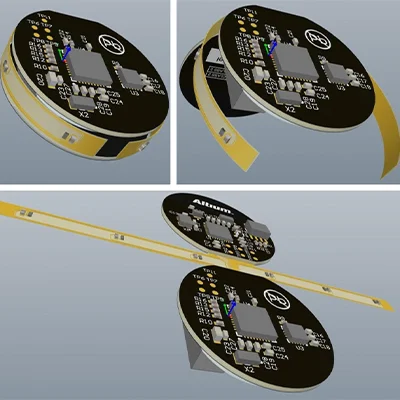

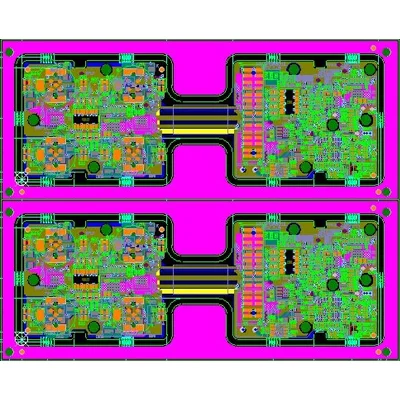

Due to their high versatility, flex and rigid-flex PCBs have been widely integrated into many applications in the medical industry. Since rigid-flex PCBs eliminate the need for connectors, they reduce cost and the amount of installation space required. Their ability to fold into tight spaces makes them useful for medical devices and equipment. As innovations in medical technology continue to reduce the size and weight of devices - especially those that are wearable or portable - rigid-flex PCBs will continue to be sought after throughout the medical industry.

Some of the more common medical devices that require flex and rigid-flex PCBs include:

Defibrillators: These devices restore a normal heartbeat by delivering an electrical shock to the heart tissue. There are different types of defibrillators, including implantable defibrillators, wearable defibrillators, automated external defibrillators (AEDs), and manually controlled external defibrillators commonly used in medical facilities. In all types of defibrillators, the PCB controls the electronics that allow these devices to function.

Drug Delivery System: The drug delivery system provides controlled release of the drug. There are many types of equipment used for these purposes. One of the most common examples is an infusion pump, which injects drugs such as insulin or analgesics into a patient. In all systems, the PCB ensures accuracy and reliability.

Handheld Devices: Many medical devices are hand-held instruments, cameras or tools, and operator comfort during use is paramount. Flex and rigid-flex PCBs allow electronic devices to fit into the space available in these devices. Another benefit of rigid-flex technology is its resistance to degradation during autoclaving of medical devices.

Handheld Monitors: Portable medical monitors can reliably monitor vital signs such as blood pressure, pulse oximetry, and body temperature. Flex and rigid-flex PCBs facilitate reliable device functionality and help reduce size and improve portability in recent designs.

Medical Imaging Equipment: Medical imaging equipment is essential for diagnosing and treating a patient's internal medical problems. Devices such as MRIs, X-rays, pill cameras, and CT scanners all rely on PCBs to operate.

Pacemaker: A pacemaker regulates the rhythm of the heartbeat by sending out electrical pulses. Some need to run continuously, while others only run periodically in a more responsive fashion. In all cases, the PCB is essential for device operation.

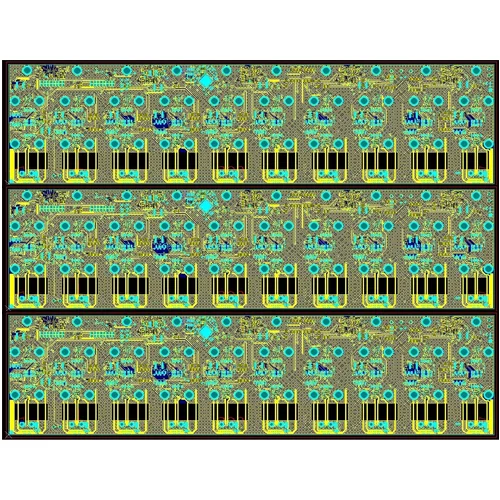

Name: Rigid-flex PCB design for medical equipment

Designable layers: 1-32 layers

Minimum line width and line spacing: 3mil

Minimum laser aperture: 4mil

Minimum mechanical aperture: 8mil

Copper foil thickness: 18-175цm (standard: 18цm35цm70цm)

Peel strength: 1.25N/mm

Minimum punching hole diameter: single side: 0.9mm/35mil

Minimum hole diameter: 0.25mm/10mil

Aperture tolerance: ≤φ0.8mm±0.05mm

Hole tolerance: ±0.05mm

Hole wall copper thickness: double-sided/multi-layer: ≥2um/0.8mil

Hole resistance: double-sided/multi-layer: ≤300цΩ

Minimum line width: 0.127mm/5mil

Minimum pitch: 0.127mm/5mil

Screen printing color: black, white, red, green, etc.

Surface treatment: lead/lead-free tin spray, ENIG, silver, OSP

Service: Provide OEM service

Certificate: ISO9001.ROSH.UL

- Previous:No

- Next:Multilayer flexible PCB design manufacturer