If we study the history of PCBs, we will notice that they gradually shift according to market demand. But this is nothing new, right? What's new in our market demand. While we thrive on technology, from optimization to best, we face a special need. Instead of making the case from the PCB, we need to make the board from the case design. But we have enough capacity to meet the demand.

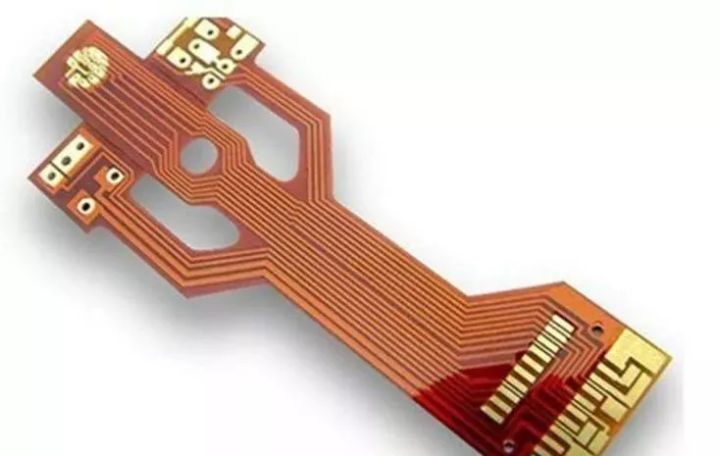

One of the popular printed circuit boards today is the flexible circuit board. Flexible PCBs allow you to assemble product circuits when the design of these products does not allow for rigid circuit boards. Therefore, they are invaluable for many electronic applications.

Flex PCBs have their own demons; they may be too flexible!

They may not be very stiff where stiffness is required. This is where human experience comes into play. We created PCB stiffeners for these cases. You may not be familiar with this name, or you may have just heard it. You are not sure what they are and where they are used.

The use of PCB reinforcement board

First, it's important to understand that PCB stiffeners are not an integral part of the board design. It exists only to provide mechanical support. When you need it, we call it a stiffener. Here are some God reasons for needing a stiffener:

Any specific area of the reinforcement board.

Maintain proper thickness in flex circuits.

Supports PCB assemblies and connectors.

Constrain flexible parts where they should be.

For better handling of thin circuit boards.

Keep certain areas of the flex circuit flat and stable.

Complies with ZIF connector specifications.

Increase the circuit bend radius at the intersection of rigid and flexible parts. This will avoid stressing the flexible part during multiple bending operations.

Basically, stiffeners are used when you need a rigid area in a flex circuit, possibly to protect the components or connectors attached there. This does not bend the circuit and protects the integrity of the part's solder joints.

PCB stiffener material

<When talking about using something, the first thing to think about is the material that makes it out of it. We usually make PCB stiffeners like most flex PCBs for FR4. FR4 ribs can also have copper features such as pads or plated holes for component mounting. Aluminum and polyimide are some other materials.

Rib thicknesses range from 0.008" to 0.059". The most commonly used thicknesses are 0.020", 0.031", 0.039" or 0.059". The thicker the PCB stiffener, the more support it provides. But each design seeks a different thickness. If you want the board to be thicker, use polyimide stiffeners. You will place them on the contact fingers as specified by the ZIF connector. It should be the connector that the flex circuit plugs into. Some common thickness requirements are 0.3mm or 0.2mm. Depending on the flex circuit material construction, the stiffener thickness can vary between 0.002" and 0.008". If you use ZIF stiffeners to thicken your board, your board may be harder than you need to.

In some cases, you may need to use other materials, such as stainless steel or aluminum, for PCB stiffeners. Correctly, you think these materials are more expensive. But you get better rigidity and heat dissipation. While there will be specific situations, you can put these expensive materials to your advantage. But most manufacturers don't think the benefits are worth the added cost of using a flexible circuit board.

PCB stiffener application

When we use ribs for Plated Through Hole (PTH) components, the ribs should be on the same side of the flex that we insert the component. This allows access to pads on the flex circuit. You can also attach stiffeners to both sides of the part. But then the assembly will require an array configuration review. Just to make sure you don't run into any complications during assembly. When we need an assembled array for flex circuit design, it is common and cost effective to include FR4 stiffeners throughout the array boundary. This ends up being a strict array. In most cases, this allows parts to run automated assembly in the same way as rigid circuit board designs. This also eliminates the need for any additional tool boards etc.

Typically, you will use heat and pressure to attach the ribs to the circuit. So basically, by thermal bonding. You can also attach PCB stiffeners using pressure sensitive adhesive. We have a wide variety of adhesives. Two popular adhesives are generally pressure sensitive adhesives (PSAs) and thermal adhesives. We use these varieties to meet specific performance requirements. They have heat exposure, chemical resistance and adhesion to a variety of materials. The type of adhesive depends on the location and/or configuration of the reinforcement. For example, if the rib does not extend to the circuit contour, in most cases it will require a PSA attachment and add an additional rib contour on the wire mesh for precise placement.

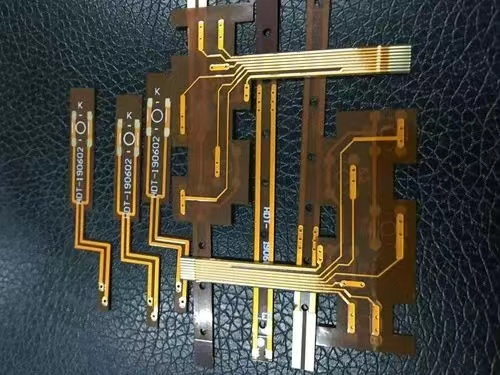

FR4 stiffeners are used for flexible PCBs in our own factory.

Before we wrap up the stiffener discussion, let's take a peek at the interesting ones.

We will now distinguish between rigid-flex PCBs and rigid PCBs based on FR4 stiffeners.

A rigid flex PCB is a flexible PCB but it is a bonded FR4 stiffener for increased rigidity during assembly. Therefore, a circuit board with stiffeners is still essentially a flexible circuit. Rigid-flex circuits are referred to as hybrid flexible circuits including rigid and flexible substrates. We laminate them into a single structure. By definition, you can see that rigid-flex circuits are not flex circuits.

There are no traces on the rigid part of the rigid flex, even on the pads. Such rigid components only increase the rigidity of the location. That said, it's just a mechanical connection between the two. However, for rigid-flex PCBs, both rigid and flex components are designed with traces, and we connect them through vias. That is, it is not a mechanical connection but an electrical connection of a rigid-flex PCB.

As we discussed in the previous point, it is also different if we talk about their connection. Rigid-flex PCBs have electrical connections, while rigid PCBs are used for mechanical support.

"Imagination is more important than knowledge. Because knowledge is limited, and imagination encompasses the whole world, stimulates progress, and breeds evolution." - Albert Einstein

What we basically want to convey is that we can guide you, train you on certain topics, but what the world needs is your imagination. Whatever we've discussed in this article may be technical, but it's human instinct. Bring this guide to PCB stiffeners to make your PCB stronger than ever.