Surface assembly method of PCBA processing

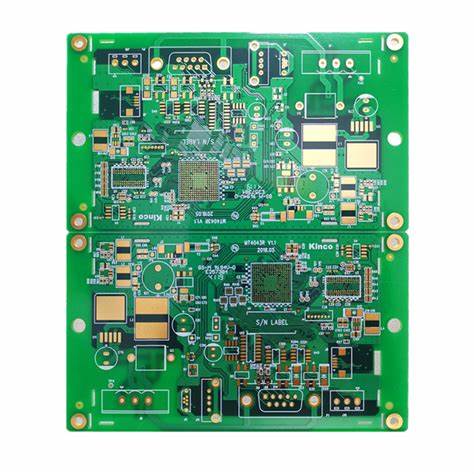

Electronic OEM foundry is also a relatively common processing cooperation method in today's electronic processing industry, which can indeed save a lot of trouble for R&D companies. PCBA processing is the main process in electronic processing, which includes a series of processes such as PCB board making, SMT patch processing, plug-in processing, testing, etc. These processes together can be called PCBA processing, and the processed finished circuit board can also be called PCBAs. Below, Guangzhou Electronics OEM manufacturer Pater Electronics will introduce some PCBA assembly methods.

PCBA processing is to form a finished electronic product after a complete set of processing processes such as PCB boarding, SMT patch processing, DIP plug-in processing, quality inspection, testing, and assembly. This processing process is called PCBA processing, and PCBA can also be said to be this Processed circuit boards. There are many kinds of PCBA, and there are several assembly methods for PCBA processing. The following professional PCBA factory Petter Technology will briefly introduce some assembly methods for you.

1. Single-sided mixed packing

single-sided mixed assembly means that SMT patch components and plug-in components are respectively distributed on both sides of the circuit board. This type of assembly adopts single-sided PCB and wave soldering processes. There are two specific assembly methods:

1. Paste first and then insert: first mount SMC/SMD on the B side of the PCB, and then insert THC on the A side.

2. Insert first and then paste: first insert THC on the A side of the PCB, and then install SMD on the B side.

Two, double-sided mixed

Double-sided mixing means that SMT patches and DIP plug-ins can be mixed and distributed on the same side or both sides of the PCB. Double-sided mixed assembly purchase double-sided patch, double wave soldering or reflow soldering. There are two commonly used assembly methods for this class:

1. SMT components and DIP components are on the same side: SMT patch components and DIP plug-in components are on the same side of the PCB; DIP plug-in components are on one or both sides.

2. There are SMT patch components on one side and both sides of the DIP component: put the surface mount integrated chip (SMIC) and THT on the A side of the PCB, and put the SMC and small outline transistor (SOT) on the B side.

3. Full surface assembly

PCBA processing assembles all circuit boards as single-sided and double-sided PCBs (or ceramic substrates). There are only SMT patch components on the PCB, no plug-in components.

1. Single-sided mixed packing

The circuit board used for assembly is a single-sided PCB. Single-sided mixed assembly means that SMT patches and DIP plug-in components are distributed on different sides of the PCB. The soldering side is a single side, and the patch side is another separate side. This type of assembly method adopts single-sided PCB and wave soldering process, and there are two specific assembly methods:

1. Paste first and insert later: that is, first mount SMC/SMD on the B side of the PCB, and then insert THC on the A side.

2. First insert and then paste method: first insert THC on the A side of the PCB, and then install SMD on the B side.

Two, double-sided mixed

The circuit board used in the assembly of this PCBA processing is a double-sided PCB. SMT patches and DIP inserts can be mixed and distributed on the same side or both sides of the PCB. In this type of assembly method, there is also the difference between posting first and posting SMC/SMD. Generally, it is reasonably selected according to the type of SMC/SMD and the size of the PCB. Usually, the first paste method is used. There are two commonly used assembly methods for this class:

1. SMT components and DIP components on the same surface: SMT component and DIP plug-in components are on the same side of the PCB; DIP plug-in components are on one or both sides. This type generally uses SMC/SMD first and then plug-in DIP.

2. There are SMT patch components on one side and both sides of the DIP component: put the surface mount integrated chip (SMIC) and THT on the A side of the PCB, and put the SMC and small outline transistor (SOT) on the B side.

3. Full surface assembly

All circuit boards assembled by this PCBA process are single-sided and double-sided PCBs, and there are only SMT components on the PCB without THT components. Since the current components have not yet fully realized SMT, there are not many such assembly forms in practical applications. There are two ways to assemble this class:

1. Single-sided surface assembly.

2. Double-sided surface assembly.