For some small partners who just contact aluminum substrate, the difference between aluminum substrate and PCB board is still questionable. Today Xiaobian for this question specifically to say to you.

Aluminum substrate is a kind of metal copper-covered plate with good heat dissipation performance. Generally, the veneer is a three-layer structure, which is respectively the circuit layer (copper foil), insulation layer and metal base. Printed circuit boards, also known as printed circuit boards, are devices that provide electrical connections to electronic components.

Circuit board belongs to the big category, aluminum substrate is just one of them, in the design is in accordance with the requirements of pcb board. Usually, what we call aluminum substrate is a single-sided PCB based on aluminum, which has good thermal conductivity and is generally used in the LED industry. Now the most commonly used LED aluminum substrate has two sides, the white side is LED pin welding, the other side is aluminum base, in contact with the heat conduction part of the general will be coated with thermal gel.

Usually we say PCB board refers to copper base. According to the different number of layers can be divided into single layer and multilayer. Relative to aluminum substrate, copper substrate and aluminum substrate. Aluminum substrate because of its special polypropylene material, better than PCB board heat dissipation, and the price is relatively expensive.

What is pcb board three anti - adhesive, what is the main function

PCB in this question refers to printed circuit board, also known as printed circuit board, refers to the equipment that provides electrical connection of electronic components. This kind of three-proof glue is very common in the electronic industry and widely used. And there is no PCB board three anti adhesive, in fact, on the PCB coated with three anti adhesive. Xiaobian today to talk with you seriously!

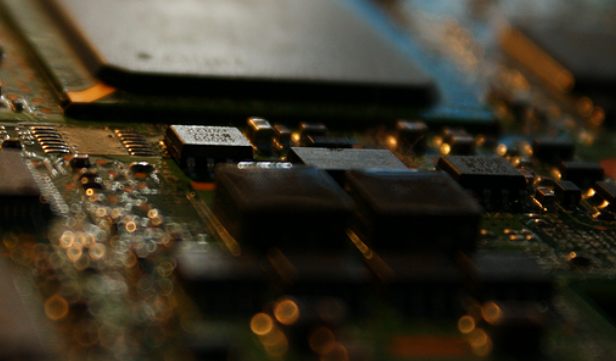

Easy to cause PCB board damage factors.

Moisture is the most common and destructive factor affecting PCB board performance. Excessive moisture will greatly reduce the insulation tolerance of the conductor, accelerate the decomposition rate, reduce the Q value and corrode the conductor. The metal part of PCB board often appears the situation of green copper, which is due to the chemical reaction between copper metal and water steam and oxygen.

Why should PCB board be coated with three anti - adhesive?

Due to the use of three rubber PCB board, not only has waterproof, moisture-proof, dust-proof "three" performance, but also has cold and heat shock resistance, anti-aging, anti-radiation, anti-salt spray, anti-ozone corrosion, anti-vibration, good flexibility and good adhesion.

The application of tri-proofing on PCB boards and parts can reduce or eliminate the degradation of electronic operating performance due to adverse operating environment effects.

Because of the different application environments of the three proofing adhesive, different end products will focus on the performance requirements of the three proofing adhesive. Refrigerators, washing machines, water heaters and other household appliances are required to be moisture-proof, outdoor fans, street lamps are required to have excellent anti-fog performance.

Three anti rubber as PCB circuit board "God of protection", its professional level can be seen. To buy this kind of adhesive products with professional needs, natural to choose professional regular brand, use more assured, such as professional R & D and production of three anti adhesive CosMolar, according to different needs, to provide customized solutions to suppliers.

Electronics are very afraid of being destroyed, if you need to use electronics in harsh environments. We strongly recommend the use of triple proofing on PCB boards for a good protective coating. With moisture-proof, anti-corrosion, shock-proof, protection function. Now, you know why to apply three anti-rubber on the circuit board, have the need of small partners do not quickly act.

Requirements for circuit board positioning holes:

Set at least two positioning holes in the diagonal of the PCB board, and note the overposition problem.

Second, the positioning hole is light, that is, non-metallic through the hole, can make it connected with the plate and high precision, its diameter error range is generally within 0.1mm.

The edge distance between the positioning hole and the plate should be at least 2mm, which is not easy to crack under the condition of ensuring the strength of PCBA.

The above, in fact, is not only the positioning of PCB board, but also applicable to the positioning of other parts and stay.

Recommended reading.

The PCBA3D model is created in Creo by invoking the library, ultimately eliminating the need for manual modeling.

Product structure - anti-static design.

"Error-proof" Design -- 10 Design principles to avoid mistakes.

Special note: The content of this article is organized, edited and original by the public account. Some pictures come from the network for learning and communication only. If copyright issues are involved, please contact us.

Suppose you have an apple, I have an apple, and we each have an apple;