Application of PCB in Medical Industry and Flexible PCB Production

PCB manufacturers, PCB designers and PCBA manufacturers explain the application of PCB in the medical industry and the assembly of flexible PCB production

The medical field is different from the past. Technological progress has revolutionized the industry. This change is more obvious in electronic diagnosis, research and treatment systems and tools. Every day, some complex electronic devices/instruments are introduced to simplify various medical procedures. This growth benefits the circuit board industry to a large extent, because without PCB, new inventions cannot be realized. In order to meet the changing needs of medical device/diagnostic mechanism manufacturers, today's PCB manufacturers make extremely simple parts into highly complex printed circuit boards. PCB manufacturers use professional high-speed laminates, copper and aluminum substrates, ceramics, and coatings to make these boards most suitable for medical applications.

Today, let's take a look at the application of PCB in the medical industry!

Application examples

Where are industrial printed circuit boards used? In short, everywhere. From simple flow system to advanced vesicle pressure measurement system, PCB shows their existence. They are engaged in the development of the following tools:

L Blood glucose meter

L Electrocardiograph

L Heart monitor

L Thermometer

L CT scanning system

L EMG activity system

L Infusion control

L Peristaltic infusion technology

L Blood pressure meter

L Magnetic resonance imaging (MRI) scanning system

L X-ray computed tomography (CT) scanning system

L Gas analyzer

L Digital cell counting device

L Pacemaker analyzer

L Ultrasonic equipment

L Laser therapeutic instrument

L Level controller

L Nerve stimulation device

L Digital temperature monitor

L ENT diagnostic instrument

L Medical data transmitter

L Gas chromatograph

Customizing options

Customization is the trend today. In terms of circuit boards, the medical industry also chooses the same method. Customers can provide correct specifications for plate size in X direction, plate size in Y direction, total number of holes, minimum routing and spacing size (inches), plate material, number of layers, surface coating, etc. manufacturer. Therefore, the manufacturer will work according to the given specifications and deliver products suitable for your application.

Description and method of flexible circuit board production assembly

In the production process of flexible circuit boards, in order to save costs, improve production efficiency and shorten the production cycle, they will be produced in the form of patchwork rather than monolithic production. There are several principles to follow when assembling flexible circuit boards.

1. On the premise that each process can be produced, try to "squeeze" the circuit board assembly. The so-called "squeeze" is to reduce the distance between adjacent boards and circuit boards, thereby reducing the size of the whole assembly, saving production materials, and reducing production costs.

2. The spacing between single plates shall be at least 2.5mm. First of all, this is to meet the requirements for positioning holes. In the process of mass production, die stamping is generally used for molding. In order to enhance the accuracy of die stamping, positioning holes need to be placed between each piece in the assembly to avoid the offset of die stamping, which will lead to the scrapping of flexible circuit boards; In the process of sample production, laser cutting is generally used for forming. In order to avoid slight deviation and avoid deviation of one piece and the whole piece, single pieces cannot be directly connected, so that they do not affect each other.

3. Etched characters shall be added to the flexible circuit board assembly, and the size and quantity of the assembly shall be briefly described, so as to facilitate the verification and verification in subsequent production.

4. Add positioning holes at the four corners of the whole assembly, and select one corner to mark different positioning holes, so as to keep the direction consistent in the subsequent process production, so as not to lead to the return of film sealing and character printing.

5. The width of the plate shall be fixed as 250mm and the length shall be within 250mm as far as possible. The larger the size of the plate, the greater the offset, the worse the production precision, and the higher the defective rate of finished products.

After reading the previous section, you should know more or less about it. Now let's briefly introduce the three methods of flexible circuit board assembly.

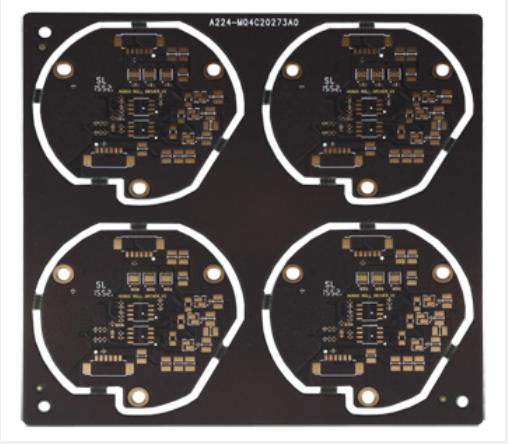

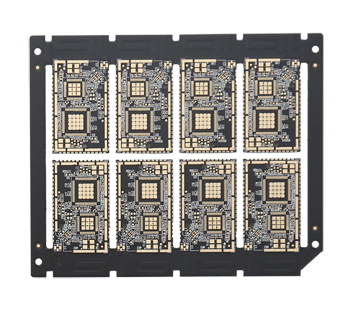

1. Regular composition. Arrayed directly in the direction of a single piece, it is most suitable for flexible circuit board assembly with regular shape, such as rectangle, square, circle, ellipse, etc;

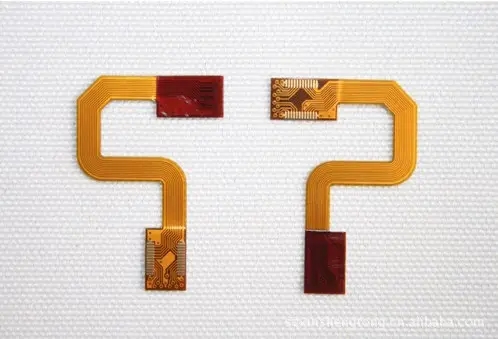

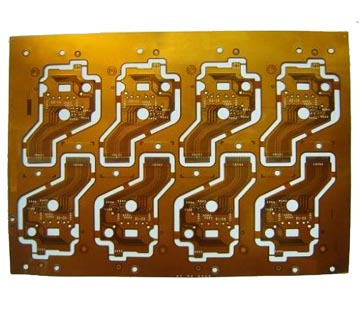

2. Oblique splicing. Tilt the single piece to a certain extent, and then array it, so as to maximize the use of the space for the assembly, such as the curved bars, folds, etc;

3. Reverse stitching. That is, combine one positive and one negative of a single PCS. PCB manufacturers, PCB designers and PCBA manufacturers will explain the application of PCB in the medical industry and the production of flexible PCB.