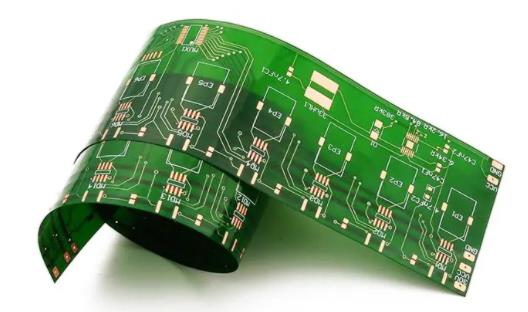

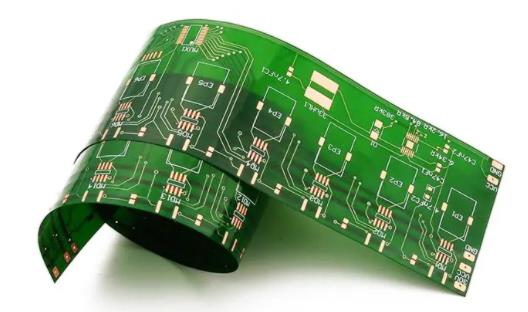

What tests are required for FPC patch before delivery? You know what?

PCB manufacturers, PCB designers and PCBA manufacturers explain to you what tests should be done for FPC patches before they leave the factory? You know what?

What reliability tests do FPC patches have?

1. Aging test

Place the FPC paster board with the test function of OK under the specific temperature and humidity conditions, and conduct repeated opening and closing, simulation function operation, load operation and other operations. Test the stability of the FPC patch board by continuously working for 24 to 72 hours. Aging test takes a long time, so large-scale batch operation cannot be carried out. In actual process, aging test is only sample sampling, and the total output of this batch of products can be determined by the qualification rate of sampling test.

2. Vibration test

In the process of delivery to customers, many FPC pasters usually cause some problems due to vibration during transportation, such as parts falling off and welding plate cracking. Through the vibration test, the vibration effect in the transportation process can be effectively simulated in the laboratory, and the hidden dangers in the welding process can be gradually exposed. To avoid batch welding and improve the overall delivery yield. At present, there is a professional simulation motion vibration workbench on the market, and the price is not high. You can buy one for 5000 yuan.

3. Surge impact test

In the process of FPC patch processing, it can normally work under normal voltage, but transient faults will occur in certain surges. Many circuit designs are imperfect. They often do not consider the fatal impact of transient voltage or current surges on the entire circuit, which requires us to sample the surge surges before mass production of FPC patches.

4. Packaging test

Packaging test is often ignored, which leads to a very interesting problem: we spent a lot of energy to improve the FPC patch board, but lost our way in the final stage of packaging and transportation. The factory shall simulate the packaging form of the FPC patch board for proper drop test.

The reliability test of FPC patch board is not limited to the above items. Each FPC chip factory can discuss with customers to determine specific reliability test plans according to the actual situation, so as to pursue higher quality manufacturing.

PCB manufacturers, PCB designers and PCBA manufacturers explain to you what tests should be done for FPC patches before they leave the factory? You know what?