PCBA board division process explained by the PCB editor

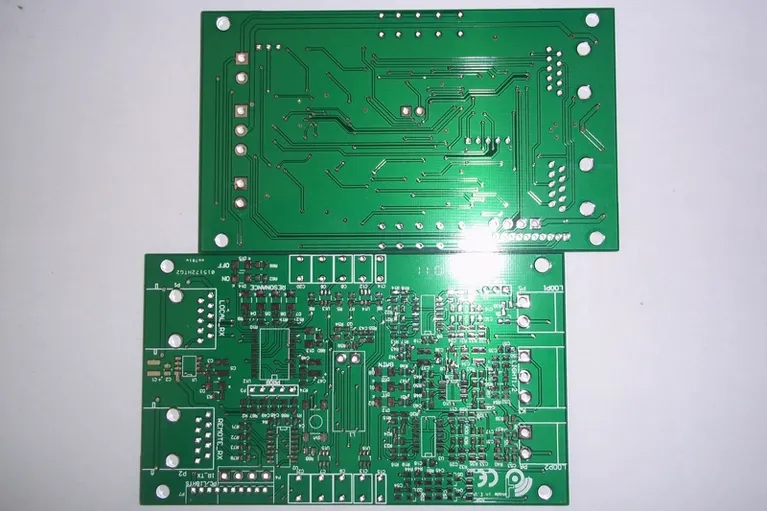

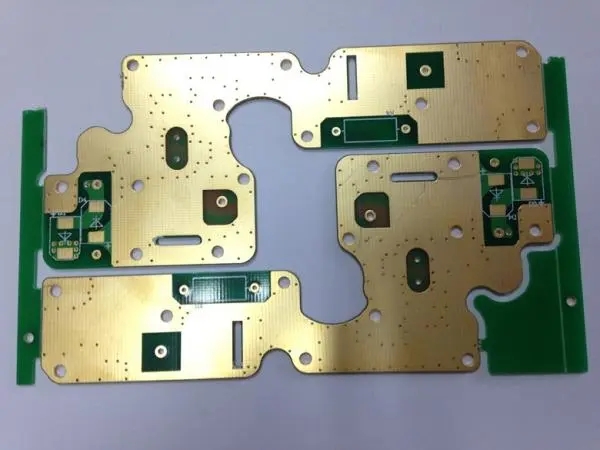

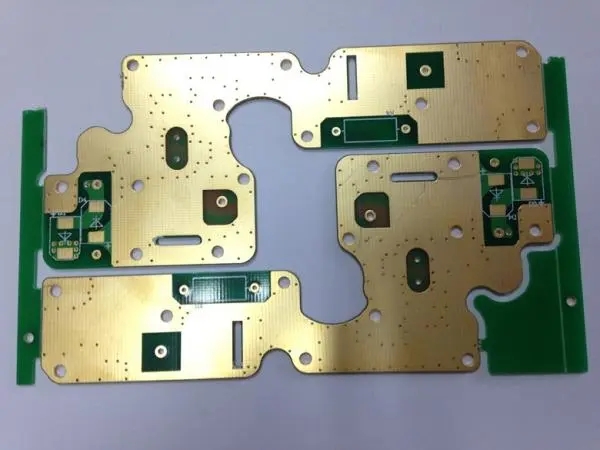

When we are processing PCBA, some PCBs are small in size. For the sake of production efficiency, we need to make PCBA panels in a way of assembly. After finishing PCBA processing, we need to divide PCBA panels. In the process of splitting, some precautions should be taken to prevent the intact PCBA board from being damaged.

During manual splitting, it is necessary to hold the lower edge of the PCBA plate with both hands when folding the plate edge, and the place 20mm away from the V-cut to avoid bending deformation, damage to the PCBA electrical circuit and parts, and tin path.

Requirements for machine partition:

1. Stable support point

Without support, the generated stress may damage the base plate and welding points. Twisting the plate or stressing the assembly during splitting can cause hidden or obvious defects.

2. Wear protective tools

Before operation, be sure to prepare for protection, and install high-frequency eye protection lighting devices to protect the safety of operators. You'd better wear a pair of eyes to protect your eyes.

3. Always wipe the machine spindle and cutter with alcohol to remove PCB dust generated in the board splitting process and maintain the normal operation of the board splitting machine.

4. After using for a certain number of times, oil the sliding rod and bearing of the board splitter to make them smooth, and check whether the screws are loose.

5. During the operation of the machine, the worktable should be kept clean, and it is better not to place other things on it to avoid the damage of tools and articles caused by things falling on the tools. Although there is an electric eye for maintenance, attention should be paid to a certain safety interval between fingers and tools in the process of use.

In general, when PCBA boards are divided, machine boards are more efficient and less damaged than manual boards. However, when the machine is divided, it is necessary to operate strictly according to the process to reduce human errors.

PCB manufacturers, PCB designers and PCBA processors will explain the precautions for PCBA board splitting.