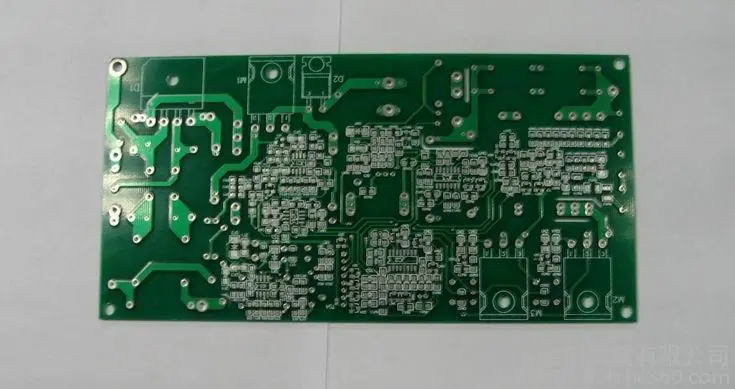

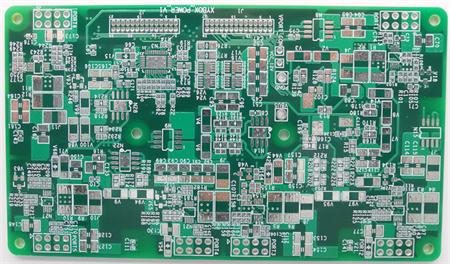

A PCB circuit board is composed of PCB circuit boards, components and software. In my opinion, the ability of maintenance personnel and inspection tools are very important when repairing PCB circuit boards. It is difficult to maintain modern PCB circuit boards only by relying on one's experience without necessary tools. It is also difficult to advocate online testers and other testing equipment without paying attention to personnel quality. When the industrial control PCB circuit board is repaired, the board you are facing will be handled differently. But * the basic idea is to find out the bad components and replace and repair them. Can we just replace all the replaceable components on the board? I have tried to replace it, but it is not good. Some components need to be debugged. Pay attention to the overall effect. Use online tester and other tools like mine sweeper, mark each component and check it once, and compare the VI curve. In this way, some faults can be found, but not all of them can be repaired. "Because the chips passed the online tester are not necessarily damaged; the chips passed the test are not necessarily undamaged." Not every component can be found in the component library. The machine tool PCB circuit board is constantly updated, so your detection tools are also constantly updated.

The quality of the maintenance personnel directly affects the success or failure of the maintenance. In the absence of any schematic diagram, a relatively unfamiliar industrial control PCB circuit board needs to be repaired. In addition to the profound hardware skills, a maintenance engineer who has a good understanding of the circuit principle and structure is also required. When he sees a strange PCB circuit board, he should carefully observe the hardware structure to determine the role of the board, and ask the customer what kind of alarm was reported when the board was installed on what machine tool. When judging the function of a PCB circuit board, it is necessary to construct the block diagram of the secondary PCB circuit board in mind, and analyze which link is faulty from the alarm information.

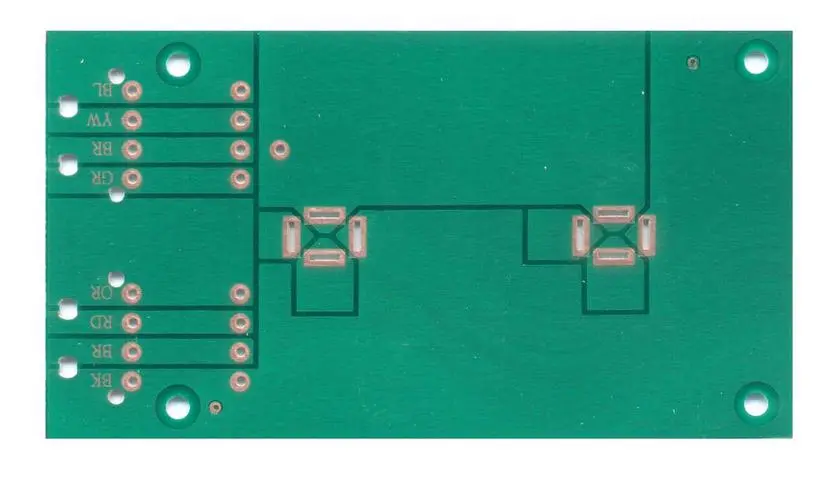

During the maintenance of industrial control PCB circuit boards, the method of the staff is also very important. The repair of PCB circuit boards is a very delicate work. There are many components and PCB circuit boards that are easy to be damaged. Therefore, the operation should be very careful and necessary auxiliary tools such as clamps are needed. Dismantling, welding, etc. shall be skilled. Before starting, the whole operation process shall be planned to avoid unnecessary damage. For chips with programs, try to back up those that can be backed up, and never move those that cannot be backed up. If it is found that the chip with program is damaged, and no spare or replacement chip can be found, then the PCB circuit board cannot be repaired.

In addition to finding the bad things to repair, * the difficulty is to check whether you have repaired them and debugged them on the computer. No matter how you repair them, * must eventually be installed on the machine tool and the PCB circuit boards sent to the customer must be good. This requires computer testing before they are sent out. Our company purchases a large number of maintenance test benches and makes tests based on the simulation of the customer's boards to ensure that the PCB circuit boards sent to the customer can be used normally, No delay in production.