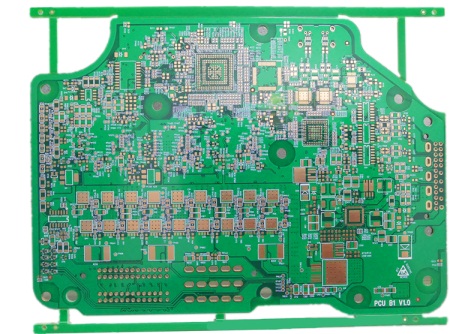

The simple truth is that it must be suitable for its intended application, not the opposite. Therefore, as a PCB designer, you will find that there are many different PCB size and shape requirements. Here are some ideas for an excellent way to use these different board dimensions.

Understand the size and shape requirements of PCB before starting layout

It can satisfy the trouble of radical schedule and design delay. It is understandable why some PCB layout designers will open their eyes to begin their PCB design. Of course, the problem is that they may lack key design information, especially in terms of size or overall dimensions or circuit board shape. When it comes to PCB layout, medium-sized design changes have become a reality. One thing you need to do is to deepen the impact of future changes without complete information from the beginning. Without good board contour data for preliminary work, you may face the possibility of having to conduct a large number of redesign in the future.

To avoid such problems, make sure that you understand the size and shape requirements of the design before starting the layout. This includes not only the X and Y dimensions of the plate, but also the height limit. This will require working closely with your entire design team to get the information you need. And don't hesitate to ask as many questions as possible. You do not want to suffer from having to replace many circuits in the design in the future, because you do not realize that there will be mounting holes where the main processor is placed.

With the required board data, you can now create a board profile using several different options.

In the past, PCB design tools were more obstacles than help when drafting objects such as circuit board outlines. Fortunately, these tools have evolved over the years and users can now create board profiles with several options.

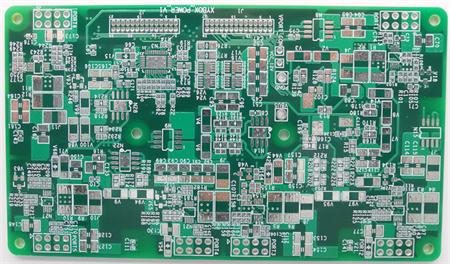

You can draw a layout tool utility that allows designers to manually draw the outline of their boards. These tools not only create the main profile for you, but also add additional profiles for layout and routing constraints. In addition, you can use the drawing function in the tool to manipulate the contour lines and create arcs or other graphic features to finally determine the required size and shape.

Many design tools will also provide you with creation wizards, which will automatically complete the drafting of the board outline. The wizard not only contains tools for creating the board outline, but also builds the board layer stack and sets the basic routing width and spacing size. Such a wizard can save you a lot of time and effort in creating the outline of the circuit board.

In addition to these drawing tools, modern PCB design CAD systems often provide you with other useful utilities to handle board contours. When dealing with complex PCB shapes, a very important function is to import mechanical CAD data into PCB database. The data can be in many different formats, including DXF, IDF, IDX and IPC-2581.

Your PCB design CAD system will read these formats and create board profiles accordingly. You can even save these profiles as templates for reuse in new designs. Of course, the key is to use a CAD system that supports all these different functions.

The importance of a complete design tool system

A good PCB design CAD system can not only support different import formats and provide you with a large number of drawing tools, but also provide many other benefits. One of the most useful functions is to be able to display PCB layout and mechanical design simultaneously in the layout tool. This allows designers to see how their layout works throughout the system design. With the 3D function of the layout tool, designers can interactively handle their component placement in real time and correct all gap errors of the designed mechanical features.