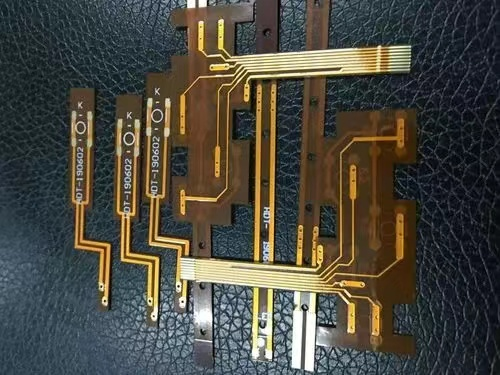

FPC flat wire is defined as a connecting wire group that can be bent to a certain extent on Baidu. Its base material is generally calendered copper, which is resistant to twists and turns and flexible. At the same time, it is also a form of functional expression of FPC. Having said that, the next content is to explain the advantages and disadvantages of FPC.

advantage

First of all, its advantages. The volume and weight of electronic products can be greatly reduced by using FPC, which is suitable for the development of electronic products in the direction of high density, miniaturization and high reliability. Therefore, FPC has been widely used in aerospace, military, mobile communications, laptops, computer peripherals, PDAs, digital cameras and other fields or products. In addition, it can also be arranged arbitrarily according to the spatial layout requirements, and move and expand freely in three-dimensional space, so as to achieve the integration of component assembly and wire connection.

shortcoming

In the process of producing products, cost should be the most important consideration. Because the soft FPC is designed and manufactured for special applications, the initial cost of circuit design, wiring and photographic plate is high. Unless there is a special need to apply soft FPC, it is better not to use it in a small amount of applications. In addition, since a lot of efforts have been invested, the later maintenance is also essential, so soldering and rework require trained personnel.

How to store FPC flat cable

Unlike other products, FPC cannot contact with air and water. So how should we store this product correctly? I believe you will find the answer after reading the following content.

Do you know the advantages and disadvantages of FPC flat cable

First of all, the vacuum of FPC FPC flexible circuit board cannot be damaged. When packing, a layer of bubble film needs to be enclosed around the box. The bubble film has good water absorption, which plays a good role in moistureproof. Of course, moistureproof beads are also indispensable.

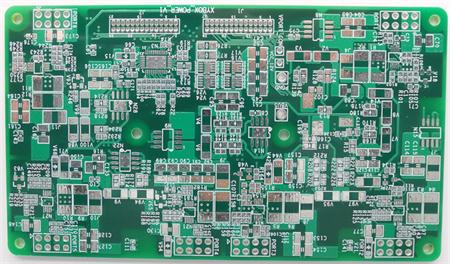

Secondly, after the box is sealed, the box must be stored in a dry and ventilated place separated from the wall and off the ground, and also avoid sunlight. The temperature of the warehouse should be better controlled at 23 ± 3 ℃ and 55 ± 10% RH. Under such conditions, PCB boards with surface treatment such as gold deposition, electrowinning, tin spraying and silver plating can be stored for 6 months, and PCB boards with surface treatment such as silver deposition, tin deposition and OSP can be stored for 3 months.

FPC flexible circuit board can be vacuum packed and stored for shipment after final finished product inspection. So why does FPC need vacuum packaging? How to store after vacuum packaging? How long is its shelf life? I believe that after reading the above content, we will have a clear answer.