PCB engineers share the benefits of flexible PCB design

Rigid PCB is very suitable for many applications, but depending on the way you choose to use PCB, you may need to improve it to a new level. At that time, flexible PCBs entered the market - they enabled you to truly customize your next PCB project, driving innovation and design forward.

The technology involved in flexible PCB (also known as flexible circuit) has developed rapidly as required. There are many different types of flexible PCB, enabling manufacturers to adapt them to many specific needs.

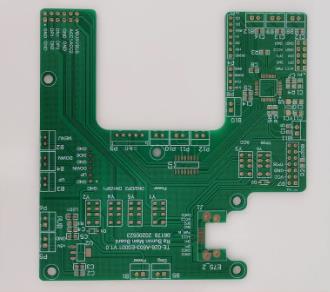

Composition of flexible PCB

Of course, one of the biggest obstacles to designing flexible PCB is the nature of PCB deployment, especially in aerospace and national defense industries. Whether the PCB is rigid or flexible, it needs to be designed to withstand any situation that may occur. The ambient or operating temperature, vibration, and violent swings of all moving parts around the PCB mean that it must be able to withstand extreme conditions at its core.

In general, the lightness of PCB seems to directly conflict with each other. However, flexible PCB can actually give manufacturers a hand in the competition. Even though they are composed of thin flexible materials, these same materials also enable flexible PCB to have high bending capacity, strength and overall flexibility.

Advantages of flexible PCB

Flexible PCBs enable designers and engineers to increasingly drive technology toward smaller sizes. Whether it is a satellite running around a satellite or a consumer MP3 player, the flexible PCB can enable the circuit to pass through a narrow space, but still maintain its integrity.

However, the advantages of flexible PCB exceed the inherent ability of bending and bending. Providing greater adjustability for designers and engineers also means customizing the design to increase airflow, thereby lowering operating temperatures. The flexibility also enables the PCB to better withstand excessive vibration. The shape factor is also positively affected. Less material means less weight, and in some applications will have a significant impact on the overall performance.

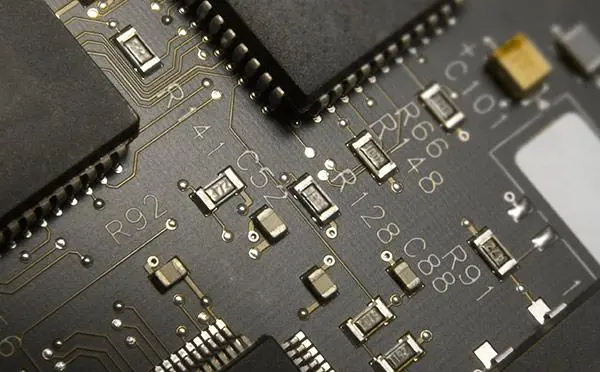

The connectivity of flexible PCB has also been improved. The circuits used by flexible PCBs have ultra-high wiring density, so they occupy less internal space than traditional wire harnesses. The flexible connection capability also means that the human error factors existing in traditional PCB components are greatly reduced, because they do not need to be connected manually.

Perhaps the biggest advantage of flexible PCB solutions is lower cost of ownership. The lack of board to board connections and jumper wires enables designers to freely design boards that can complete the work they should do without making necessary compromises when using rigid PCBs. Circuit board processing, circuit board assembly and processing manufacturers explain that engineers share the benefits of flexible PCB design.